This article introduces the types, profiles, materials, interface methods, applications and advantages of timing belts.

About Yonghang About Timing Belts user manual | Yonghang

What are Timing Belts

Synchronous belts, also known as timing belts, are a new type of transmission belt that combines the advantages of belt drives, chain drives, and gear drives.

You can envision it as a rubber belt with teeth. It transmits motion and power by meshing its teeth with corresponding grooves on the pulley.

Its most fundamental characteristic is “synchronization”: this means there is no relative slippage between the driving pulley (input) and the driven pulley (output), ensuring a precise transmission ratio. In other words, when the driving pulley completes one revolution, the driven pulley will also rotate the exact corresponding number of revolutions.

Design of Timing Belts

There are two main components of a timing belt: the molded cords inside the timing belt for carrying the torque load and the plastic compound used to shape the teeth and cover the cord itself. These components are available in different types of materials for different types of timing belts. To determine the type of materials to use, one has to consider the end use of the belt. Timing belts’ cords are usually made out of fiberglass, polyester, or Kevlar. They transmit power in the drive system through the belt.

The cord and the belt teeth are oriented at right angles with each other so that the cord can linearly transmit the power applied to the belt. An example of a belt that carries huge loads is the serpentine belt utilized in automobile engines. In smaller drive systems, elongation of the belt is minimal.

Belt stretch does not exist practically in small drive applications since the cord materials are so strong in relation to the loads that they transmit. Too high loads can cause breakage of cords as well as belt teeth jumping, or cogging over the pulley teeth. During the construction of timing belts, a mold in which the plastic is injected is present. The plastic is then injected into the mold that already contains the wound cord and accurate tooth profiles that are cut into the mold.

There is always a different mold available for each different belt length since there must be the exact number of teeth in the mold as there are on the finished belt. This is done to produce a finished, continuous belt that has no beginning or end. A mold can produce a sleeve that has a width of 18 to 36 inches having the number of teeth that is desired. The sleeve is accurately trimmed into the desired belt widths by special slitting tools. Food processing belts are made from urethane, when FDA requirements must be met. With urethane, any particles are less likely to be seen because urethane can be colored or left in a clear natural state. This is a different case with black neoprene belts.

The standard material for timing belts is neoprene because it exhibits good wear characteristics and from the mold, it accurately holds the tooth profile. To reduce wear, neoprene belts have a facing that is made from nylon fabric. To meet special requirements for low dust or particle applications like office copiers, clean rooms or medical, engineered polymers are used. To generate less dust than neoprene, an EPDM polymer is used as a core with all tooth wear surfaces over coated with nylon. This also ensures the accurate holding of tooth profile for many hours of use compared to urethane or neoprene belts.

Timing Belt Teeth

Strong timing belt teeth are reliable for keeping the crank and cam shafts synchronized, and there is a wide range of metric pitches for the teeth. Pitch is the distance measured from the center of onetooth to the center of another adjacent tooth on a timing belt. Pitches impact other timing belt pulley factors that include the number of teeth and diameter. Older timing belts are designed using trapezoidal-shaped teeth, when it comes to teeth design.

However, new manufacturing techniques that allow for curved teeth to combat the challenges with noise and lifespan that are common in multiple belts designed using trapezoidal shaped teeth. An important point to note on the construction of timing belts is that a timing belt with shortened width offers improved performance due to the reduction of weight and friction.

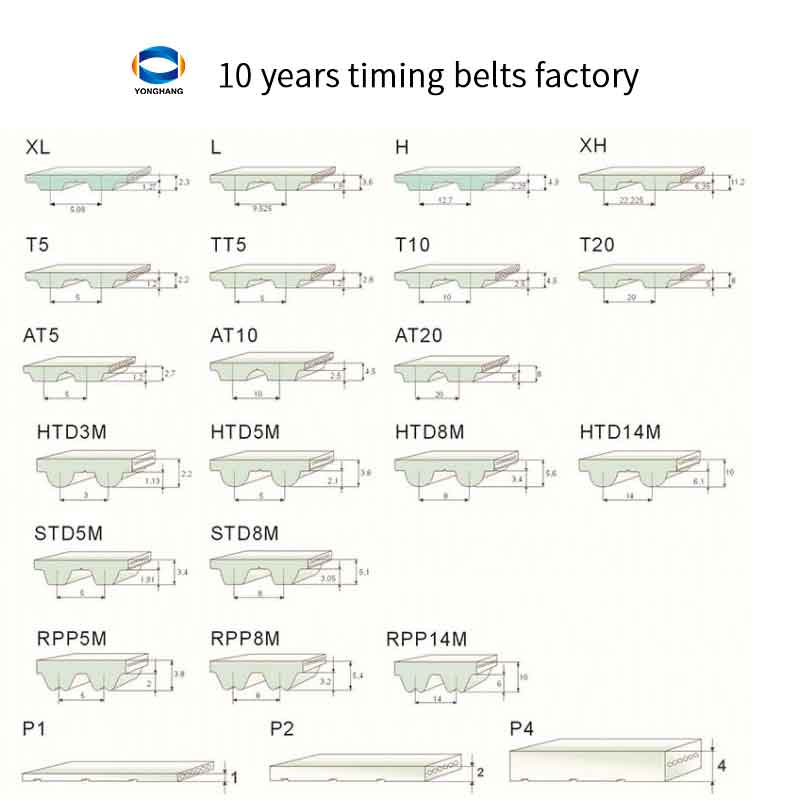

Timing Belt Tooth Profiles

There are many different arrangements of timing belt teeth depending on the desired application and environment.

As already mentioned before the first arrangement is the trapezoidal arrangement, while curvilinear tooth profiles are used by more modern timing belts.

Trapezoidal Timing Belts

For transmitting forces, trapezoidal teeth are extremely effective. However, when the levels of torque and speed are high, teeth of this blunt shape tend to wear down fast. Trapezoidal teeth remain common despite their faults, and for precision conveying and linear positioning belts, they are typically the primary choice

Curvilinear Timing Belts

Curvilinear toothed timing belts have a smoother and more rounded tooth shape. These types of belts reduce the risk of tension loss and they alleviate the high concentration of force that is experienced by trapezoidal teeth. Curvilinear timing belts have drawbacks of their own despite the great improvements they offer over other tooth designs. Curvilinear belt teeth are prone to a greater amount of play between the grooves of the pulleys and the teeth of the belt. This difficulty is referred to as backlash, and results in less accurate positioning of the timing belt, and the performance of the timing belt is potentially decreased.

Modified Curvilinear Timing Belts

These types of belts seek to combine the strengths possessed by both curvilinear and trapezoidal tooth profiles. Modified curvilinear belts have a shallower tooth depth and steeper sides. As a consequence, they are capable of transmitting forces of higher speed and torque effectively, without putting a sacrifice on durability. These types of belts are often primary choice industrial applications that are demanding.

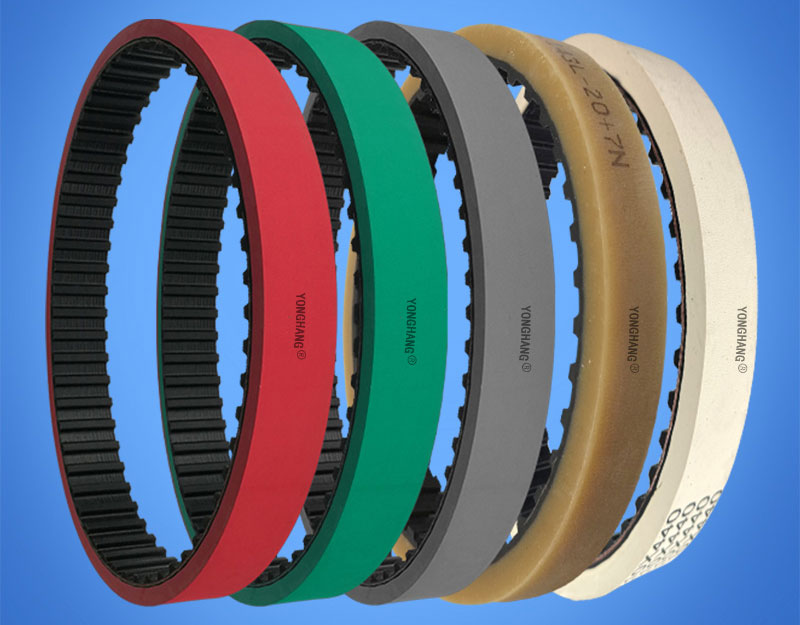

Rubber coated Timing Belts

Rubber is the most famous timing belt construction material used across industries and applications. Many of the internal combustion engines found in a great diversity of packing machine use timing belts that are made out of some type of rubber or rubber compound. Even though rubber is the most commonly used material for timing belts, it does have some drawbacks.

Timing belts made from rubber are notorious for stretching and breaking relatively quickly if they are subjected to high temperatures and quantities of motor oil found in the Environmental Conditions. Nowadays, there are multiple types of rubber materials that are temperature resistant due to the advancement of technology. These rubber materials are now used to prolong the lifespan of your timing belts, and improve their resistance to distortion.For example, Silicone, EPDM

Greater strength and traction is also offered by improved rubber compounds and reinforcing fibers. These improved rubber compounds also guard against sheared teeth or any other potential damage to the belt.

Polyurethane Material timing belts

Polyurethane has become a famous option for timing belts due to its properties which are resistance to high temperatures, natural greater elasticity and resistance to harmful effects of oil. For a broad range of applications, timing belts made from polyurethane are long lasting and offer extremely energy efficient solutions.

Polyurethane timing belts are capable of delivering high tensile strength and they also provide higher loading capacities. These higher loading capacities are crucial for the production of optimal torque. These types of belts are preferred by many in the industry because their cleaning and maintenance is relatively easy. Polyurethane is the best choice of material for making timing belts for multiple types of power transmissions and roller conveyor systems.

Open Ended PU Timing Belts

Open ended timing belts are available in different types of materials including extruded, thermoplastic polyurethane. These types of belts are dimensionally stable and they are made ideal for use in linear drive systems by their precise positioning.

They have a high spring rate and their tooth shear strength is excellent. For a linear drive with stiffness and repeatability that is high, the steel tension members are recommended over aramid fiber. The stiffest and strongest open ended timing belt is the move-series AT10 or AT15. Open ended timing belts are available in 50m rolls or specified cut length.

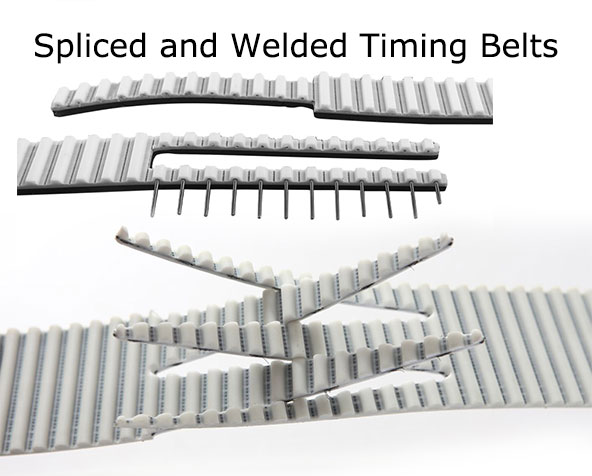

Spliced and Welded PU Timing Belts

In many general purpose applications, spliced and welded are utilized. Their construction type is preferred in conveying as well as for profiles and backings that are welded. At the start of these types of belts, there is a length of roll stock that is open that contains finger splices cut into the belt and is then welded together using heat.

Spliced and welded timing belts have the same sealed edges and smooth back as open ended timing belts. These types of belts have 50 percent of truly endless belt strength because they are welded. They can purchased it in the length for need.

Truly Endless PU Timing Belts

Truly endless polyurethane timing belts are extruded without a weld. This makes truly endless timing belts the strongest construction type, making them ideal for applications that involve power transmission. Truly endless timing belts have steel tension members as a standard and are found in different types of materials.

The AT is the most famous tooth configuration for more tooth shear strength. Double sided timing belts are also available for drive systems whose shaft direction changes. These types of belts are available with unsealed edges. If they are closely inspected, a pin-hole location of the tension member is found, where it exited the belt during the process of extrusion.

Applications and Advantages of Timing Belts

The various applications of timing belts include:

Automobile Timing Belt

Timing belts are used in timing belt/cam belt systems that are present in most automobiles on roads across the whole world. It can be said that the mobility of the modern world is greatly made possible by the efficient operation of automobile timing belts. The toothed timing belts available in automobile applications are belts of high performance.

They consist of special materials for the coordination of the rotational motion of the crankshaft of the engine with the camshaft of the engine. To ensure the intake/exhaust valves in the engine’s combustion chambers open properly at the precise moment of expansion or compression, coordinated precision is necessary. It is also necessary for ensuring sustainable continuation of the engine’s combustion process. This coordination determines the pace of the engine, and if it doesn’t function properly, combustion will not be possible.

A high level of synchronicity must be maintained extremely by these belts, and they must also be able to perform under high rotational speeds. The timing belts must be strong enough to operate under high temperatures, wherever automobiles can be driven.

Steering gear Timing belt

This is a specially designed timing belt. It is of a bevel gear type and helps to facilitate the movement of the steering wheel.

Sewing Machines Timing belt

A sewing machine is another everyday example of a belt driven system. The timing belt is utilized to transfer motion between the sewing pulleys and the motor. Although it is not a high performance, high load application, high speed system like the treadmill and the automobile, the sewing machine remains an excellent example of the application of synchronous timing belts. A sewing machine’s belt system is used to transfer the main drive motor’s rotary motion to the larger spoon head to drive the sewing mechanism.

Timing belts are also utilized in 3D printers, conveyor systems, CVT automatic transmission and industrial automation products.

Advantages of Timing Belts

When timing belts are compared to flat or round belt drives they may have disadvantages like:

· Timing belts have high costs

· They require initial alignment with the timing pulley.

· Timing belts are only used to transfer relatively low power.

· They transfer power at relatively smaller distances.

However, these disadvantages are outweighed by the benefits which include:

· Timing belts produce less noise.

· They have low vibrations.

· Timing belts have no slippage problem.

· Their mechanical efficiency is high, up to 98 percent.

· They have constant velocity ratios.

· Timing belts require low maintenance.

Considerations When Choosing a Timing Belt

The various considerations when selecting a timing belt include:

Material Choices

Clearly seen, there are many different materials used in timing belts due to their own different specifications to which they can handle certain circumstances. As already mentioned earlier, the different types of materials for timing belts include urethane, neoprene, rubber, fabric etc. Each material has its own unique properties that make it the most suitable for a particular application.

Dimensions and Speed

Apart from the type of material, there are also some characteristics that must be considered when opting for a timing belt. These characteristics will influence the smooth operation of the equipment. These characteristics are listed below.

Belt Width

Belt width deals with the plausible amount of tracking force of the belt. Wider timing belts result in greater tracking forces.

Belt Length

Shorter belts have greater tracking forces because of the connection that is between tensile cords and belt molds.

Pulley Diameter

Small-sized pulleys create greater tracking forces. The diameter of the pulley must be greater than that of the belt.

Belt Installation Tension

Due to the impact of various loads of torque gathered by belt tracking, the timing belt’s magnitude of belt installation tension does matter.

Environment Concerns

Timing belts are as fragile as glass. If the operating environment affects the process of this synchronous device, it might be hampered from working. Dust particles can also cause malfunctions in the timing belt system.

Functionality

The function of the timing belt depends on where it is going to be used. Not every material is capable of handling the requirements for all industries. Thus there is a need to conform to the application in selecting a timing belt.

Design

This refers to choosing a standard design or custom design of a timing belt. The design of the timing belt involves questions about the amount of precision required.

Conclusion

Timing belts come in many different types with each type suitable for a certain application. Each timing belt is made out of a specific type of material that makes it perform best in a certain or particular environment. If you are to choose a timing belt for a particular application, always consider the type of material it is made from. This ensures optimal results in the performance of the timing belt for the particular application you choose it for. The replacement of a timing belt is also critical and time reliant.

FAQ

1.Can I have a sample order for Belt?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

2.May I customize the belt to print my logo?

Yes. Please inform us formally before our production and confirm the design firstly based on our sample

3.What are the payment terms?

Western Union, Ali Secure Pay or T/T (company account and personal account)

Yonghang Advantages

1.We have a manufacturing base of 10,000 square meters and more than 8,000 sets of molds. We use advanced manufacturing equipment at home and abroad to specialize in the production of rubber products, plastics, and conveying machinery products.

2.Various conveying systems and parts, rubber flat belts, rubber traction belts, PU timing belts, ATM belts, sausage machine belts, printer belts

3.YONGHANG 10 year focus on Transmission Belt Custom manufacturer.

4.EXCELLENT ENTERPRISE Yonghang company has a production base of 10,000 square meters. Our company is a manufacturer integrating R&D, production and sales。

Guangzhou Yonghang Transmission Belt Co., Ltd. , is focus on power transmission belt production factory.YONGHANG has 10,000+㎡ of Production workshop, The introduction of domestic and foreign advanced manufacturing equipment more than 50+, and so on. Mold more than 8000+, An annual output of various types of transmission belt 500,000+. The main products for the rubber belt series of products, such as coated timing belt, rubber flat belt, haul off belt, PU timing belt, ATM belt, sausage timing belt, printer Belt, Pulleys,and so on. YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on. YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership. We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details