The main differences between T-series and AT-series timing belts lie in their tooth profile design, which affects their load capacity, operational noise, and precision. While both have the same trapezoidal tooth shape, the AT-series features a modified design with a curved root that offers better performance

What are differences between T series and AT series timing belt?

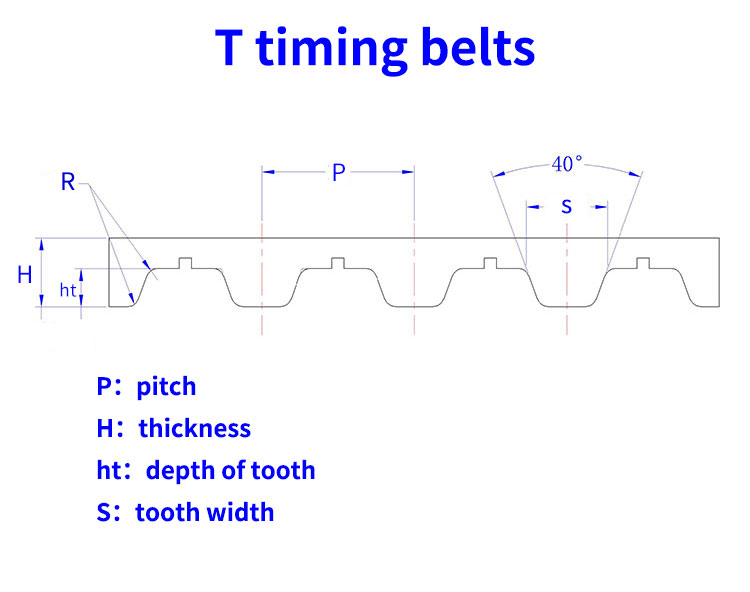

· Tooth profile: trapezoidal tooth shape.

· Types include:T2.5 T5 T10 T20 (There is also a specially customized size T9)

· Performance: Under low-speed, heavy-load conditions, it provides a robust, durable, economical, and reliable synchronous drive solution.

· Applications: heavy construction machinery, paper machinery, pumps, compressors, textile machinery.

T series PU Timing Belt Data Sheets

| Trapezoidal Profile | T2.5 | T5 | T10 | T20 | T9 |

| Tooth Pitch t [mm] | 2.5 | 5 | 10 | 20 | 9 |

| Belt Thickness H [mm] | 1.3 | 2.2 | 4.5 | 8 | 4.5 |

| Tooth Height h1 [mm] | 0.7 | 1.2 | 2.5 | 5 | 2.5 |

| Tooth width S [mm] | 1.5 | 2.67 | 5.32 | 10.14 | 4.6 |

| Tooth Angle 2β [°] | 40 | 40 | 40 | 40 | 40 |

| Rotational Speed | approx.10000ft/min | approx.10000ft/min | approx.8000ft/min | approx.5000ft/min | approx.7800ft/min |

| Peripheral Speed | approx. 50m/s | approx. 50 m/s | approx. 50 m/s | approx.30-40m/s | approx.approx.40~50m/s |

| Ultimate Tensile Strength [N/10mm belt width] | 1000 | 1572 | 3912 | 6400 | 3120 |

Imperial pitch series timing belts

· Tooth profile: trapezoidal shape.

· Types include:MXL XXL XL L H XH XXH

· Performance: Under low-speed, heavy-load conditions, it provides a robust, durable, economical, and reliable synchronous drive solution.

· Applications: heavy construction machinery, paper machinery, pumps, compressors, textile machinery.

· It is worth noting that the pitch of the inch trapezoidal timing belt is all measured in inches, such as 0.08 inches, 0.2 inches, 0.375 inches, 0.5 inches, and so on.

Imperial pitch PU Timing Belt Data Sheets

| Trapezoidal Profile | MXL | XXL | XL | L | H | XH | XXH |

| Tooth Pitch t [in] | 0.08″ | 0.125″ | 0.2″ | 0.375″ | 0.5″ | 0.875″ | 1.25″ |

| Belt Thickness H [in] | 0.0449″ | 0.0598″ | 0.09″ | 0.142″ | 0.169″ | 0.441″ | 0.618″ |

| Tooth Height h1 [in] | 0.02″ | 0.03″ | 0.05″ | 0.07″ | 0.09″ | 0.25″ | 0.375″ |

| Tooth width S [in] | 0.0449″ | 0.068″ | 0.101″ | 0.183″ | 0.241″ | 0.495″ | 0.75″ |

| Tooth Angle 2β [°] | 40 | 50 | 50 | 40 | 40 | 40 | 40 |

| Rotational Speed | approx.10000ft/min | approx.10000ft/min | approx.10000ft/min | approx.7800ft/min | approx.7000ft/min | approx.5000ft/min | approx.4900ft/min |

| Peripheral Speed | approx.50 m/s | approx.50 m/s | approx.50 m/s | approx.40~50m/s | approx.40m/s | approx.30m/s | approx.25-30 m/s |

| Ultimate Tensile Strength [N/10mm belt width] | 1000 | 1200 | 1230 | 2450 | 3750 | 6000 | 11450 |

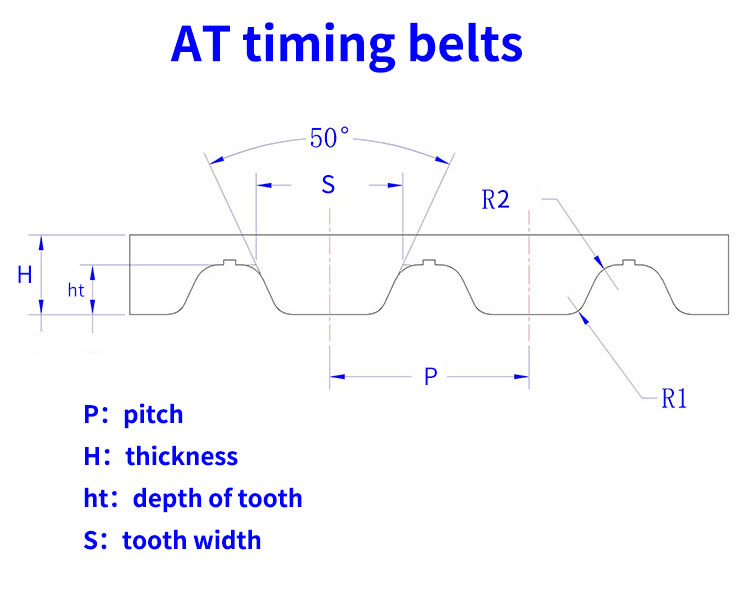

· Tooth profile: Curved tooth root (50°angle)

· Types include:AT3 AT5 AT10 AT15 AT20

· Performance: Under low-speed, heavy-load conditions, it provides a robust, durable, economical, and reliable synchronous drive solution.

· Applications: heavy construction machinery, Ceramic cutting machine production line, glass edging machine,pumps, compressors, textile machinery.

| Trapezoidal Profile | AT3 | AT5 | AT10 | AT15 | AT20 |

| Tooth Pitch t [mm] | 3 | 5 | 10 | 15 | 20 |

| Belt Thickness H [mm] | 1.9 | 2.7 | 4.5 | 6.5 | 8 |

| Tooth Height h1 [mm] | 1.1 | 1.2 | 2.5 | 3.8 | 5 |

| Tooth Angle 2β [°] | 50 | 50 | 50 | 50 | 50 |

| Rotational Speed | approx. 20000 ft/min | 10000 ft/min | approx. 10000 ft/min | approx. 8000 ft/min | approx. 6500 ft/min |

| Peripheral Speed | approx. 80 m/s | approx. 80 m/s | approx.60 m/s | approx. 50 m/s | approx. 40 m/s |

| Ultimate Tensile Strength [N/10mm belt width] | 1600 | 2800 | 6800 | 7680 | 8960 |

| Feature | T-Series (Trapezoidal Tooth) | AT-Series (Modified Trapezoidal Tooth) |

| Tooth Profile | Standard trapezoid (40°angle) | Modified Trapezoidal Tooth (50°angle) |

| Primary Advantage | Good all-around performance | Higher load capacity, reduced backlash |

| Load Capacity | Standard | Up to 30% higher than equivalent T-series |

| Operational Noise & Precision | Standard | Lower noise and higher transmission precision |

| Common Models | T2.5, T5, T10, T20 | AT5, AT10,AT15, AT20 |

| Compatibility | Not compatible with AT-series pulleys | Not compatible with T-series pulleys |

When selecting a belt or replacing an existing one, keep these points in mind:

Focus on Performance Needs: If your application demands higher power transmission, greater precision, and quieter operation, the AT-series is generally the better choice. For standard duty applications, the T-series may be sufficient.

Prioritize Compatibility: T-series and AT-series belts and pulleys are not interchangeable. You cannot use a T5 belt on an AT5 pulley, or vice versa. Always match the series exactly.

Check the Pitch: Both series share the same pitch (e.g., T5 and AT5 both have a 5mm pitch), so the part number does not indicate compatibility. The physical tooth profile is the deciding factor.

I hope this detailed comparison helps you make an informed decision. If you can share more about your specific application, I might be able to offer more tailored advice.

Belt Material

PU: T series timing belt in polyurethane material with reinforced steel or Kevlar cord, which has characteristics of oil resistance, chemical resistance and high load capacity.

Rubber: T series timing belt in rubber material with fiberglass core featured with heat resistance and aging resistance.

Key Points for Timing Belt Model Selection

For example, T20 and AT20

1. The AT20 synchronous belt teeth have a larger contact area with both sides of the pulley teeth compared to the T20: The T20 has a tooth angle of 40°, while the AT20 has a tooth angle of 50°. Under the same number of teeth, module, and width, and when space is limited, the AT20 transmits greater force. Therefore, the T20 model is rarely used in general mechanical design now; the AT20 is used directly!

2. AT20 timing belts are designed for 30% greater load capacity than T20: The larger tooth profile and significantly wider tooth surface of AT20 minimize tooth deformation, distributing the load over a larger area.

Load, speed, transmission accuracy and environmental conditions all needed to be considered comprehensively when selecting timing belt models. T series more economically can be used in situations with light loads and low speed.AT is recommended in scenarios with heavy loads. If there is oil and dust in the environment, it is necessary to match the polyurethane material toothed belt, which has better wear resistance and chemical corrosion resistance than rubber material.

There was a ceramic factory Ceramic cutting machine production line stopped production due to frequent breakage of the timing belt, after the investigation we found that the original design used T20 belt, but the actual load peak exceeded the rated value by 30%. After replacing AT20 belt and adding tension pulley, continuous operation for half a year without fault, transmission efficiency increased by 20%. This case shows that accurate calculation of operating parameters and reserving 20% safety margin can effectively extend the life of the timing belts.

Contact Details