What are differences between HTD timing belt and STD timing belt?

Tooth Design Differences: Core Differences

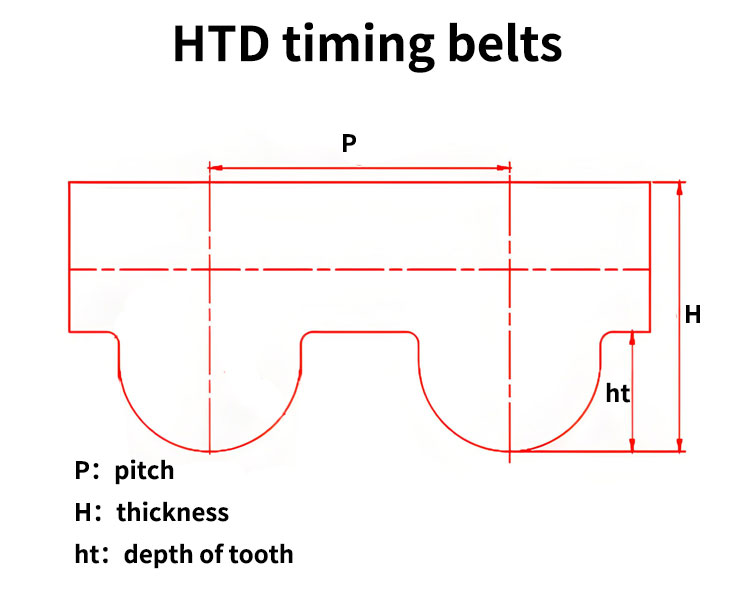

HTD timing belt is arc tooth timing belt,Types include:HTD3M HTD5M HTD8M HTD14M, HTD timing belt has a special tooth profile and deep tooth design to increase torque carrying capacity and reduce slippage, so it performs well in high load, low speed or high torque transmission.

![HTD timing belt data table]()

HTD timing belt data table

| type | HTD 2M | HTD 3M | HTD 5M | HTD 8M | HTD 14M | HTD 20M |

| P(mm) | 2 | 3 | 5 | 8 | 14 | 20 |

| H(mm) | 1.38 | 2.4 | 3.6 | 6 | 10 | 15 |

| ht(mm) | 0.75 | 1.22 | 2.06 | 3.38 | 6.02 | 8.4 |

![STD timing belt data table]()

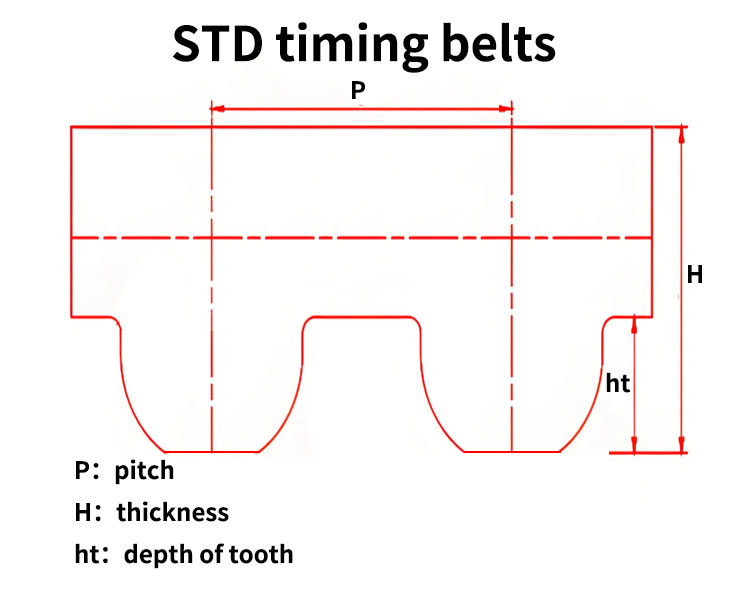

STD timing belt data table

| type | STD 2M | STD 3M | STD 4.5M | STD 5M | STD 8M | STD 14M | STD 20M |

| P(mm) | 2 | 3 | 4.5 | 5 | 8 | 14 | 20 |

| H(mm) | 1.36 | 1.94 | 2.81 | 3.4 | 5.6 | 10 | 13.2 |

| ht(mm) | 0.84 | 1.14 | 1.71 | 1.91 | 3 | 5.3 | 8.4 |

STD timing belt is flat-top semi-arc timing belts:STD3M,STD4.5M,STD5M,STD8M,and STD14M are high-torque and high-precision timing belts.Compared to HTD, it has an additional pitch of 4.5M timing belt. This is a more precise drive system. renowned lawn mower belts are made with the S4.5M size.

The STD timing belt is an upgraded version of the HTD timing belt with stronger functions,also known as high-torque timing belt,use for heavy-duty applications requiring high precision and stability,such as medical instruments,winning equipment and CNC machine tools.

Comparisons of Performance and Application Scenarios

| Feature | HTD Timing Belt | STD Timing Belt |

| Tooth Profile | Full, rounded arc | Semi-arc with a flatter top |

| Primary Advantage | Higher torque capacity due to the rounded, deeper teeth | Greater stability and precision under load due to the flatter tooth top |

| Performance | experience slippage or tooth jumping more easily than STD | More stable, less slippage, and constant transmission ratio |

| Noise | Can be noisier than STD | Quieter operation, even at high speeds |

| Applications | General-purpose high-torque applications industrial machinery | Heavy-duty applications requiring high precision and stability |

Comparisons of Belt Material

PU: timing belt in polyurethane material with reinforced steel or Kevlar cord, which has characteristics of oil resistance, chemical resistance and high load capacity.

Rubber: timing belt in rubber material with fiberglass core featured with heat resistance and aging resistance.

Key Points for Timing Belt Model Selection

Load, speed, transmission accuracy and environmental conditions all needed to be considered comprehensively when selecting timing belt models. HTD series can be used in situations with light loads and high speed. STD is recommended in scenarios with heavy loads, low noise and low speed. If there is oil and dust in the environment, it is necessary to match the polyurethane material toothed belt, which has better wear resistance and chemical corrosion resistance than rubber material.

There was a food factory packaging line stopped production due to frequent breakage of the timing belt, after the investigation we found that the original design used HTD8M belt, but the actual load peak exceeded the rated value by 30%. After replacing STD-8M belt and adding tension wheel, continuous operation for half a year without fault, transmission efficiency increased by 18%. This case shows that accurate calculation of operating parameters and reserving 20% safety margin can effectively extend the life of the timing belts.

Why Choose Yonghang Circular Arc Tooth Timing Belts?

Yonghang is a factory of timing belts, offering both T-type and circular arc timing belts. We provide a variety of materials, including rubber and PU, and can add various coatings such as red glue, APL, foam, transparent PU, silicone, felt, and rough-top PVC.please contact us directly regarding specific requirements for different coatings, special fabrication or to discuss the possibility of any other technical changes.