In the previous article, we discussed the differences between HTD timing belts and STD timing belts.

Now let's examine the differences between RPP timing belts and STD timing belts.

In the previous article, we discussed the differences between HTD timing belts and STD timing belts.

Now let's examine the differences between RPP timing belts and STD timing belts.

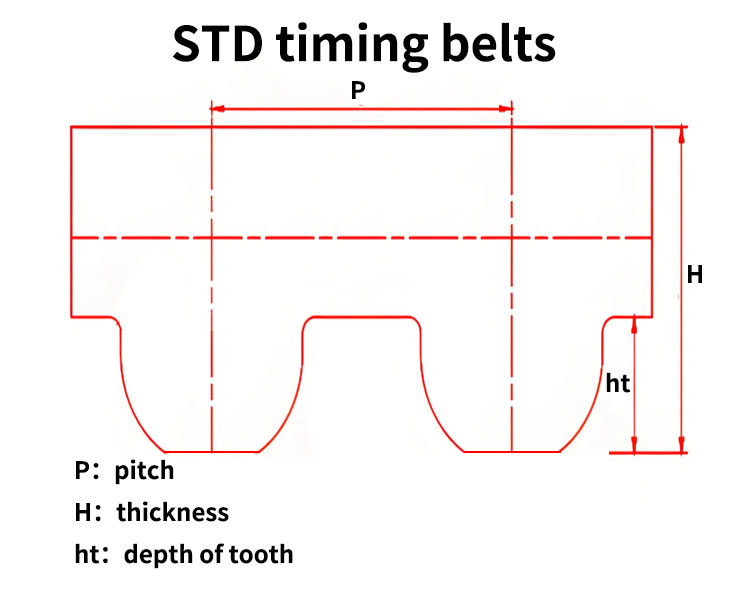

STD timing belt data table

| type | STD 2M | STD 3M | STD 4.5M | STD 5M | STD 8M | STD 14M | STD 20M |

| P(mm) | 2 | 3 | 4.5 | 5 | 8 | 14 | 20 |

| H(mm) | 1.36 | 1.94 | 2.81 | 3.4 | 5.6 | 10 | 13.2 |

| ht(mm) | 0.84 | 1.14 | 1.71 | 1.91 | 3 | 5.3 | 8.4 |

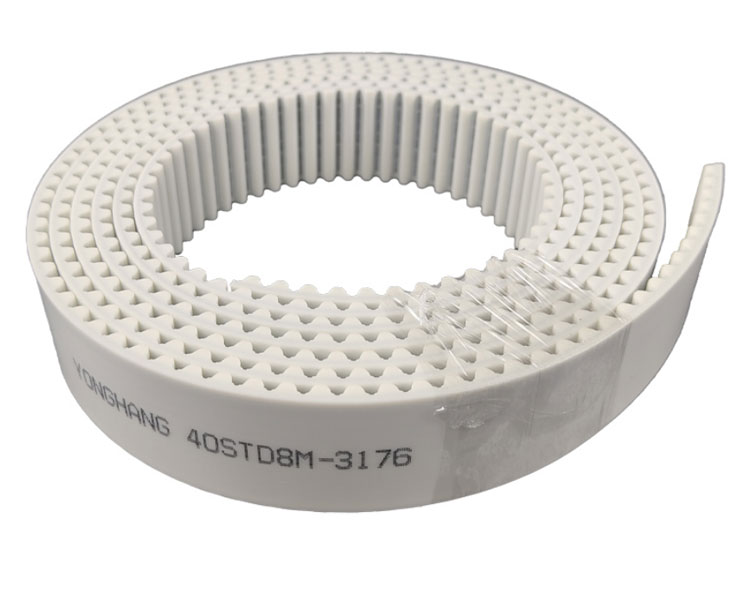

STD timing belts in a modified curvilinear belts,the feature is flat-top semi-arc tooth, commonly used types include:HTD3M HTD5M HTD4.5M HTD8M HTD14M, (abbreviated as. S3M. S5M S4.5M S8M, S14M)

The STD timing belt is an upgraded version of the HTD timing belt with stronger functions,also known as high-torque timing belt,use for heavy-duty applications requiring high precision and stability

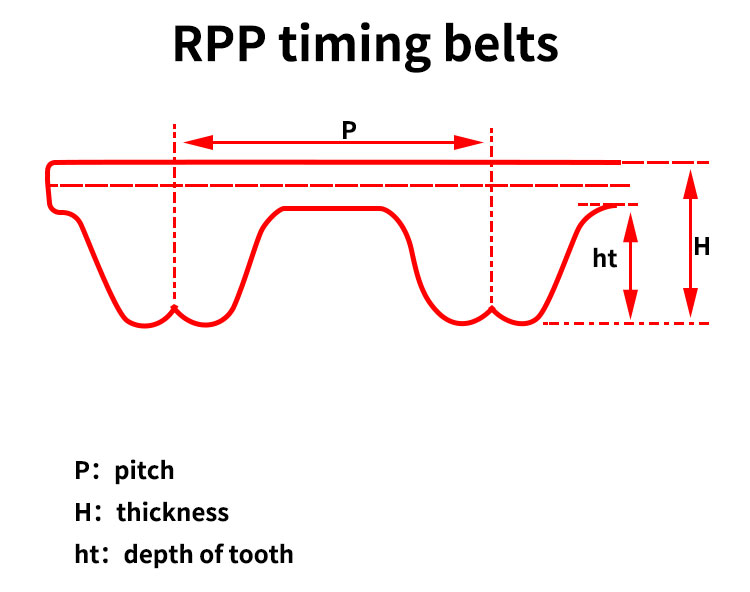

RPP timing belt data table

| type | RPP2M | RPP3M | RPP5M | RPP8M | RPP14M |

| P(mm) | 2 | 3 | 5 | 8 | 14 |

| H(mm) | 1.36 | 1.9 | 3.5 | 5.5 | 10 |

| ht(mm) | 0.76 | 1.15 | 1.95 | 3.2 | 6 |

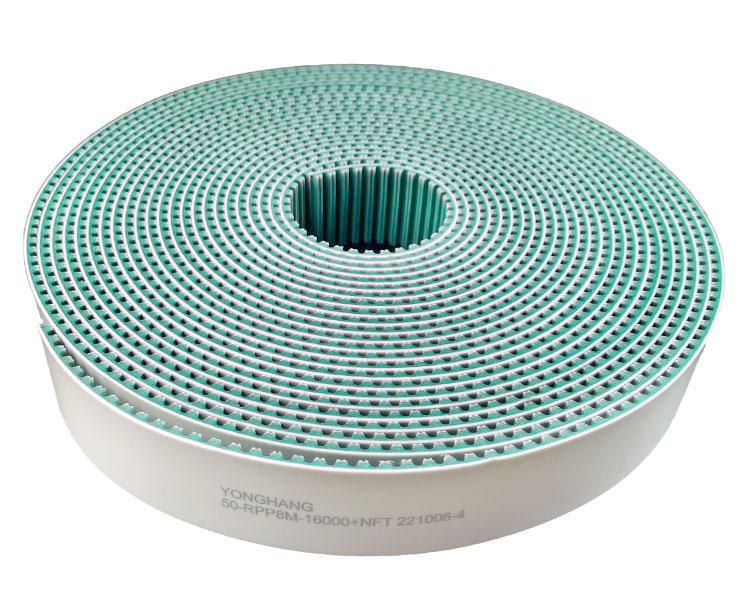

RPP modified circular arc tooth belt, ,the feature is Parabolic ("M" type) with a notch,commonly used types include: RPP3M RPP5M, RPP8M, RPP14M, (abbreviated as. P3M. P5M P8M, P14M)

RPP Timing belts usually have tooth cap green cloth PAZ/NFT,The M-type tooth design of RPP timing belts reduces the contact surface between the belt and pulley, The design can significantly improve the distribution of stress.significantly lowering noise levels and enhancing flexibility during bending. Compared to STD timing belts, they offer a smaller turning radius.

The RPP tooth profile better combines the advantages of HTD and STD and has been improved.

Key differences summarized

| Feature | STD Timing Belt | RPP Timing Belt |

| Tooth Profile | Semi-circular arc with a flat top | Parabolic ("M" type) with a notch |

| Performance | Stable, high-precision, low-noise upgrade from HTD | Higher precision and flexibility for high-speed applications |

| Best Use Case | General high-torque applications | High-speed, high-precision, and low-noise applications |

STD timing belt

· Tooth profile: Semi-circular arc with a flat top.

· Construction: An upgrade from the older HTD (High Torque Drive) belts.

· Performance: Offers better stability, higher precision, reduced slippage, and lower noise than HTD belts.

· Applications: Suitable for applications requiring high torque, accuracy, and stability, including various industrial and high-performance systems.

RPP timing belt

· Tooth profile: Parabolic or "M" shaped tooth with a notch at the top.

· Construction: An improved version of both HTD and STD belts.

· Performance:

· The notch allows for better meshing and reduces noise.

· The parabolic profile improves tooth flexibility and load-bearing capacity.

· Designed for high-speed, high-precision, and low-noise operations.

Applications: Ideal for high-end applications like precision robots and high-end printers. Such as: servo motors, CNC machine tools, industrial robots, precision conveying equipment, etc.

Key Points for RPP STD Timing Belt Model Selection

· For new equipment designs or replacements, prioritize the RPP series. It represents a more advanced and reliable technology. Although the per-unit cost may be slightly higher, its extended lifespan, enhanced reliability, and superior performance typically result in lower overall cost of ownership.

· STD timing belts should only be retained when maintaining legacy equipment originally designed for STD pulleys. STD and RPP pulleys are not interchangeable due to fundamentally incompatible tooth profiles. Forced mixing will result in accelerated wear and failure.

Why choose RPP timing belts instead of STD timing belts?

· Enhanced Durability: The unique circular arc tooth design minimizes wear and extends belt life, providing a longer-lasting solution for your machinery.

· Superior Power Transmission: The innovative tooth shape reduces the risk of slippage, ensuring efficient and reliable power transmission even under heavy loads.

· Quiet and Smooth Operation: Thanks to the advanced design, these belts reduce vibration and noise, offering a quieter and smoother operational experience.

· High Efficiency: With reduced friction and improved tooth engagement, the Circular Arc Tooth Belts deliver greater energy efficiency, helping to lower operational costs.

· Customizable Solutions: Puteken offers a range of sizes and materials to meet specific application requirements, ensuring a perfect fit for your equipment.

· Reliable Performance: Whether in high-speed or high-torque environments, these belts provide consistent, high-performance operation across a wide range of industries.

Especially in scenarios such as automatic doors and windows, elevator hoists, and stage curtain opening and closing, where lower noise levels are required, RPP timing belts are the preferred choice for the industry.

We hope this article can be of help you. If you have any suggestions or wish to obtain a quotation, please contact us.

Contact Details