As a core component of mechanical transmission systems, the specifications and model numbers of timing belts directly impact transmission accuracy and system reliability. Different tooth profiles (such as inch teeth, T-teeth, RPP teeth, HTD, STD, ATK teeth, BATK teeth) follow unique model identification rules. Accurate interpretation of these parameters is crucial for selection and replacement. The following systematically explains how to read the model numbers for various tooth profile Timing belts.

How to Read Timing Belt Number?

This article is from the Yonghang Timing Belt Team, Lucy.This article will guide you on how to read the model number of the timing belts

I. Inch-Tooth Timing Belts (Imperial Trapezoidal Teeth)

Inch-tooth belts use imperial pitch. Model numbers typically begin with a letter denoting the tooth profile, followed by numbers indicating pitch and width.

Common series include:

MXL Series: Pitch 0.08 inches (2.032 mm), widths 3 mm, 6 mm, 9 mm. For example, “MXL-060” denotes a width of 0.6 inches (15 mm). An alternative notation is: B80MXL0.32. Here, the number after “B” indicates teeth count (80 teeth), ‘MXL’ represents the 0.08-inch (2.032 mm) pitch, and “032” signifies a width of 0.32 inches (8 mm).

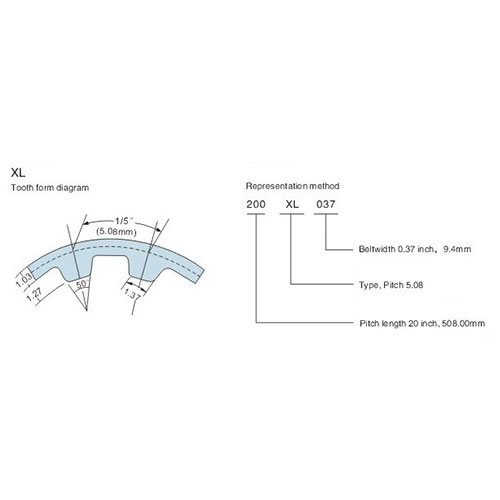

XL Series: Pitch 0.2 inches (5.08 mm), widths 10 mm, 15 mm, 25 mm. Model examples: “458XL120”“458 ”denotes length 45.8 inches (1163.32 mm), “120” indicates width 1.2 inches (30 mm).

L/H/XH/XXH Series: Pitch increases sequentially (0.375 inches to 1.25 inches), with widths extending up to 200 mm. Model examples like “XXH200” denote “200” as 2 inches (50.8 mm) wide.

Reading Method:

Identify tooth profile code: Letter prefix (e.g., MXL, XL) determines profile type.

Interpret pitch: Series corresponds to fixed pitch (e.g., MXL = 0.08 inches).

Determine width: The suffix number directly indicates width (in mm). Note that some models may omit the unit or specify it as mm, e.g., L-1905-25: L denotes tooth profile, 1905 is length in mm, 25mm width. Imperial tooth lengths are typically in inches; conversion to mm usually involves decimals (conversion formula: 1 inch = 25.4mm).

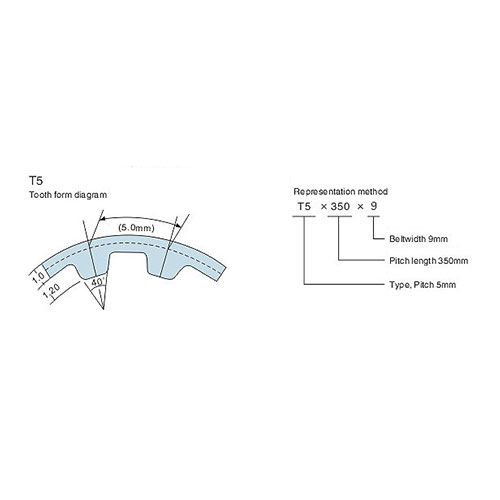

II. T-Tooth Timing Belts (Trapezoidal Teeth)

T-tooth Timing belts use metric pitch. Model numbers begin with “T” followed by the pitch value, length, and width. Common specifications:

T5 Series: 5 mm pitch, widths 15 mm, 25 mm, 40 mm. Model example: “T5-500-30” where ‘500’ denotes 500 mm length and “30” denotes 30 mm width.

T10 Series: Pitch 10 mm, widths 20 mm, 30 mm, 50 mm. Model example: “T10-1000-40” where ‘1000’ denotes length 1000 mm and “40” denotes width 40 mm.

Reading Method:

Tooth Profile Identification: The letter “T” denotes trapezoidal teeth.

Pitch Value: Subsequent digits (e.g., 5, 10) indicate pitch (unit: mm).

Length Parameter: Suffix digits represent length (unit: mm).

Width Parameter: Follows the length specification (unit: mm).

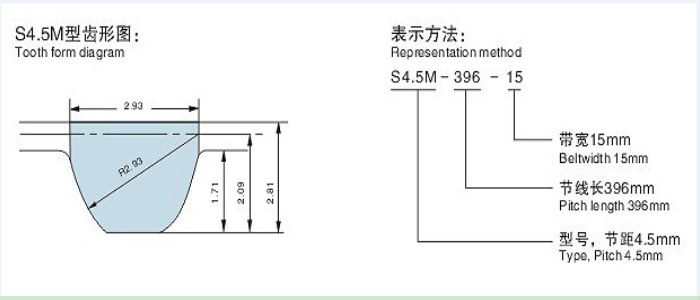

III. Arc-Tooth Timing Belts

· HTD: Represents full-arc-tooth timing belts with a complete circular arc tooth profile.

· STD/S: Represents flat-top semi-arc-tooth timing belts (STD is an upgraded version of HTD with flat-top semi-arc tooth crests).

Middle Number and Letter Combination

· Pitch parameters: Numbers like “3M,” “5M,” or “8M” denote pitch (in millimeters). For example, 8M indicates an 8mm pitch.

· STD model variations: STD models are labeled as S3M, S5M, etc., matching HTD's 3M and 5M pitches but featuring different tooth profiles.

Suffix parameters

· Belt width: The final digit (e.g., 30) indicates a width of 30 mm.

· Length: Denotes the pitch line length (e.g., 1040 represents 1040 mm)

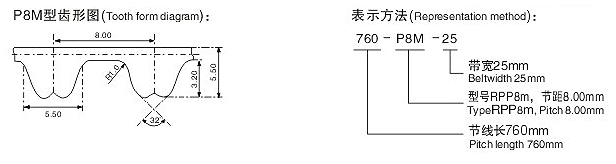

III. RPP Tooth timing Belts (Rabbit Tooth Profile)

RPP teeth are specifically designed for high-speed start-stop applications. Model numbers begin with “RPP” followed by pitch and width. For example:

RPP5M: 5 mm pitch, widths 15 mm or 25 mm. Model names like “RPP5M-800-25” denote ‘800’ for 800 mm length and “25” for 25 mm width.

Reading Method:

Tooth Profile Code: “RPP” denotes rabbit-tooth profile.

Pitch Value: Numeric part (e.g., 5) indicates 5 mm pitch (unit: mm).

Width Parameter: Final digit represents width (e.g., 25) indicates 25 mm belt width (unit: mm).

Length: Denotes pitch line length (e.g., 800 indicates 800mm)

IV. ATK Tooth timing Belts (Self-Tracking Timing Belts with Guide Strips)

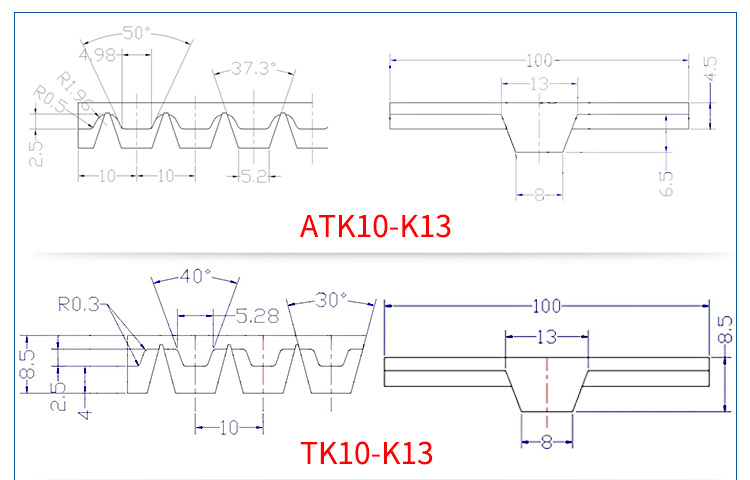

ATK teeth represent high-precision T-shaped anti-drift timing belts. Model numbers begin with “ATK,” followed by pitch guide strip specifications, length, and width. For example:

ATK5K6: Pitch 5 mm, width 20 mm or 30 mm. Model like “ATK5K6-800-30”: ATK denotes timing belt model, 5 indicates 5mm pitch, K6 signifies guide strip base width 6mm (guide strip size 6x10), 800 represents length (mm), “30” denotes width 30 mm.

Reading method:

Tooth Profile Identification: “ATK” denotes AT-type tooth profile guide rail.

Pitch Value: Numeric portion (e.g., 5) indicates pitch (unit: mm).

First letter K followed by pitch value

Second letter K followed by guide rail base width

Length: Represents pitch line length (e.g., 800 denotes 800 mm)

Width Parameter: Final digit indicates width (unit: mm)

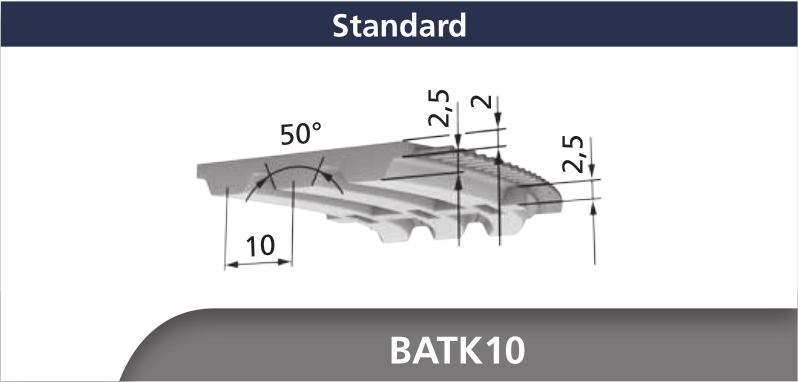

V. BATK Tooth timing Belts (AT Curved Tooth Self-Guiding Integrated Guide Strips)

BATK teeth feature a self-tracking integrated guide strip design. Model numbers begin with “BATK” followed by pitch length and width. For example:

BATK10M: Pitch 10mm, width 50mm, 75mm, or 100mm. Model examples: “BATK10M-5000-50” denotes 5000mm length and 50mm width.

Reading Method:

Tooth Profile Code: “BATK” identifies AT curved tooth self-guiding integrated guide strip teeth.

Pitch value: The numerical part (e.g., 10) indicates pitch (unit: mm).

Length: Denotes the pitch line length (e.g., 5000 represents 5000mm).

Width parameter: The final digit denotes width (unit: mm). Note that guide strips may include additional identifiers (e.g., “K8” or “K13”).

General Reading Steps and Precautions

Observe Marking Location: Model numbers are typically printed on the side or edge of the timing belt. Use a magnifying glass to identify worn markings.

Measure and Verify: If markings are unclear, measure the pitch (distance between adjacent tooth centers) and width, then cross-reference with Yonghang's specification table.

Cross-Check: Combine tooth profile type (trapezoidal/arc/special teeth) with dimensional parameters to avoid misreading.

Consult Professional Support: For ambiguous models, contact suppliers or utilize online tools. Our Yonghang technical experts provide online assistance; alternatively, submit an email for a response within 24 hours.

Mastering these methods enables accurate identification of various timing belt models, ensuring efficient and reliable operation of your transmission system.

Contact Details