The distance or time periods for the replacement of the timing belts are recommended by the manufacturer. Failure to replace a timing belt in time will result in a complete breakdown or catastrophic failure of an engine, This article discusses the causes of timing belt failures and provides relevant suggestions.

Causes of Timing Belt Failure

2025-10-09

Failure of a Timing Belt

The timing belt tensioner can be replaced at the same time when the belt is being replaced, this is common. In some engines in which the timing belt runs the coolant pump, the coolant pump is also typically replaced. The common failure modes of timing belts are either delamination and unraveling of the fiber cores or stripped teeth. Stripped teeth leave a section of the belt where the cog of the drive will slip. Breakage of the timing belt, because of high tensile fibers’ nature is not common. The timing belt can be slowly wearied by debris and dirt that get mixed with oil and grease. This causes premature belt failure.

The correct belt tension is critical in the life expectancy of a timing belt. If the belt is too loose, it will whip, and if it is too tight, it will whine and apply excess strain on the cogs’ bearings. In either case, the life of the belt is drastically shortened. The belt tensioner also fails, apart from the belt itself. The other failures that can occur are from various gear and idler bearings and these cause the belt to derail.

Causes of Timing Belt Failure

The various causes of timing belts failure include:

Misalignment Failure

One of the main causes of timing belt drive failure is misalignment. Misalignment is caused by uneven or excessive tooth wear, tensile failure and belt tracking. To increase the lifespan of your timing belt, always check and align your shafts and timing pulleys. This saves lots of downtime.

Excessive Load

Excessive load is the cause of the shearing of teeth in a timing belt. Excessive load or shock loads can also cause uneven excessive tooth wear and tensile failure. To eradicate this problem, the drive must be redesigned.

Under-Tensioned Belt

Ratcheting, which is the skipping of teeth, is due to a timing belt being under-tensioned. Under-tension results in the excessive or uneven wearing of the teeth, and excessive drive noise. To set the correct tension on a timing belt, use a tension gauge.

Weak Drive Structure

If there is an excessive vibration of a drive, or your timing belts are under belt stretch, there might be a weak drive structure. To stop this problem, try reinforcing the structure of the drive.

Damaged or Worn Pulleys

The lifespan of a timing belt is reduced by damaged or worn pulleys. If the teeth are worn out, they cause the belt to wear and or damage. The belt can be cut by nicks or gouges. It is important to inspect and replace pulleys that show signs of wear.

Failure Modes of timing belts

There are numerous causes for timing belt failure modes, and sometimes determining the specific failure mode can be challenging. The purpose of this application memorandum is to define, illustrate, and identify common timing belt failure modes, enabling us to implement appropriate preventive measures and corrective actions.

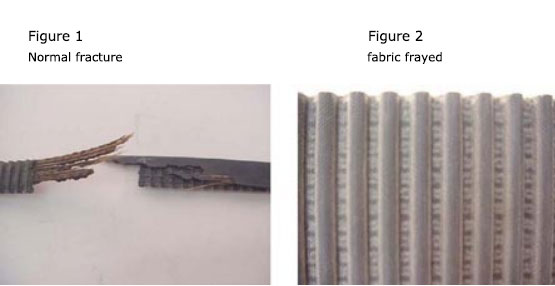

Normal Wear and Failure of Belts: After 2 to 3 years of operation, belt failure becomes normal when the core wire reaches its fatigue life. After prolonged operation, belt failure due to core wire reaching its fatigue life represents an ideal failure mode. Figure 1 shows a ragged, 45-degree serrated fracture pattern typical of normal fatigue failure in the belt core wire.

timing belt teeth may also fail, but this is not considered an ideal failure mode. During prolonged operation, while the belt maintains its initial size and shape, tooth wear occurs. Exposed fibers from the belt's fabric layer cause the teeth to appear rough and frayed, as shown in Figure 2.Timing Belts operating for 2 to 3 years require no further corrective measures.timing belt lifespan varies significantly depending on application and various objective factors. Influencing factors include transmission power rating, environment, belt installation tension, belt-pulley matching, pulley quality standards, and even how the belt is cut, packaged, transported, and installed.

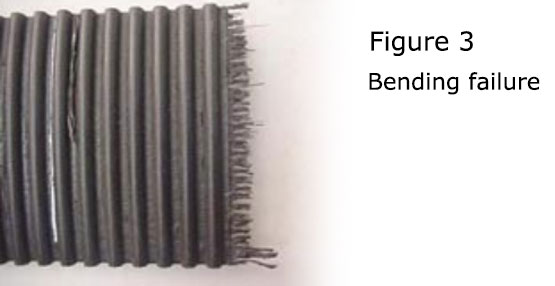

Timing belt buckling failure: Buckling failure in timing belts typically manifests as a straight alignment of core fibers along the fracture surface, as shown in Figure 3. This failure mode occurs when the belt core fibers are bent to an extremely small diameter. Abrupt bending subjects the belt's core fibers to immense stress, causing them to bend and become damaged, thereby reducing the belt's tensile strength. Belt kink failure is the most common failure mode, typically associated with improper belt operation, insufficient installation tension, undersized pulley diameter, and foreign objects within the pulley.

Causes of timing belt buckling due to improper operation include: improper storage, improper packaging, and improper handling before and during belt installation. A belt operating under insufficient tension may continue to skip teeth until it reaches an acceptable tension level—a phenomenon known as self-tensioning.

Self-tensioning is most clearly observable at the slack end of the timing belt or where the belt teeth enter the pulley groove. When self-tensioning occurs, the timing belt teeth pop out of the pulley groove until increased tension at the tight end forces the teeth back into the groove. When the belt is forced back into the pulley groove, it often causes a sudden, intense bending at the contact point between the timing belt and the pulley. This bending can damage the belt's core wires. This type of core wire damage is referred to as kinking. If the tension on the tight side is insufficient to force the belt teeth back into the pulley groove, the belt will skip teeth, which can also result in kinking failure or damage to the timing belt teeth.

When a timing belt engages a pulley with an undersized diameter, it can damage the belt's core or cause buckling failure. Pulley diameters and idler pulleys smaller than the specified minimum, the presence of idler pulleys between the belt and pulleys, or even manually bending the belt at a sharp angle can all lead to buckling failure.

Foreign objects entering the drive system can also cause belt kinking. These objects create sharp angles between the timing belt and pulley, causing the core wire at that point to bend. Forcibly prying the belt onto the pulley with tools can also damage the belt. After damage from foreign objects or improper tool use during installation (such as screwdrivers), the belt may not fail immediately, but its overall service life will be reduced.

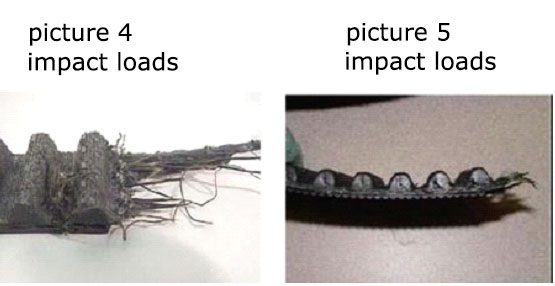

Impact Loads: When intermittent or periodic torque loads demanded by driven equipment exceed normal levels, these impact loads surpass the force the timing belt itself can withstand, resulting in impact loads within the drive system. This often accelerates timing belt failure. Conventional V-belts can mitigate impact loads through momentary slippage, but timing belts must transmit all loads.

Severe impact loads can cause the belt core to fracture in a coarse, uneven pattern, as shown in Figure 4. Teeth in the belt may develop root cracks and/or tooth breakage after instantaneous impact loads in the pulley. If the impact load occurs only once or repeats cyclically at a fixed position on the belt, the remaining teeth may still appear normal. Figure 5 illustrates how root cracks can propagate within a tooth. Cracks originating at the root may sometimes extend to the tooth tip. When excessive cracks accumulate, the tooth may shear off, leaving only a portion of the tooth intact.

Impact loads generated by driven equipment may be an inherent part of transmission system operation or may arise from occasional, severe conditions such as blockages. If impact loads in the transmission system are unavoidable, the core strength of the timing belt must be enhanced, or intermittent operation can be achieved by replacing the timing belt drive with a V-belt.

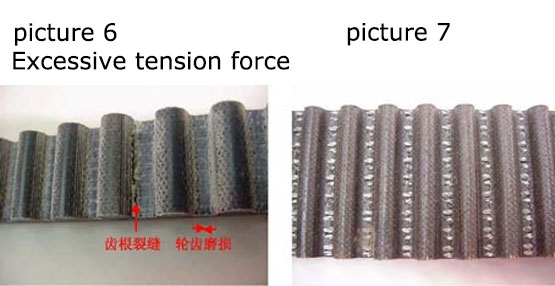

Excessive belt installation tension: Over-tensioning the timing belt can cause shearing or fracturing of the belt teeth. Many over-tensioned belts exhibit clear signs of gear tooth wear on their tooth surfaces. Figure 6 shows an example of a compressed surface area and root cracking on a timing belt. Cracks at the tooth roots typically propagate through the core wire to adjacent cracks, causing individual belt teeth to gradually detach. Figure 7 shows wear marks on a large pulley caused by a belt subjected to excessive tension. Excessive surface pressure on the belt leads to widespread wear, ultimately exposing the belt's core wire. To prevent such wear issues, the appropriate belt installation tension must be precisely set.

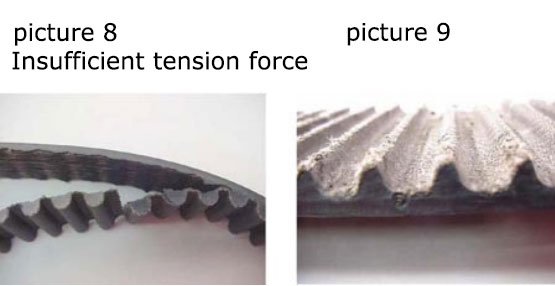

Insufficient tension during timing belt installation: Insufficient tension during installation in transmission systems under moderate to high loads can also lead to premature belt failure. Typically, belt failure caused by insufficient tension manifests as tooth skipping. Tooth skipping occurs when belt teeth climb out of their corresponding pulley grooves, causing their roots to lose load-bearing capacity. Continued transmission load acts on the belt's sides, bending the teeth and causing them to skip. As teeth roll, rubber tears from the root along the core cord. As the rubber tear propagates, the belt teeth begin to detach from the belt in strips, as shown in Figure 8. Failure due to excessive tooth jumping may appear similar to insufficient adhesion between the rubber and the cord. However, unlike tooth jumping failure, failure caused by insufficient adhesion typically leaves the exposed cords within the belt neat and orderly.

When the belt teeth climb out of the pulley groove and self-tension, the timing belt is prone to tooth skipping before rubber tearing and tooth detachment occurs. Damage to the belt core caused by tooth skipping often leads to premature strength failure of the belt. The damage pattern resembles both clean breaks from flexural failure and jagged, angled fractures from impact loads. If the belt does not skip teeth and continues running during self-tensioning, excessive tooth wear frequently occurs. This type of tooth wear, termed hook-shaped wear, results from mismatched belt teeth and pulleys, as shown in Figure 9. Hook-shaped wear stems from insufficient installation tension and unstable drive systems experiencing center distance variations under low tension conditions.

Increasing the installation tension of a belt can typically prevent premature tooth skipping and hook-shaped wear. If increasing the installation tension still fails to prevent belt failure, it may indicate that the drive system structure is insufficiently robust to prevent misalignment. To enhance belt performance, it is essential to increase the supporting force of the transmission structure. If raising installation tension is impractical, enlarging pulley diameter allows the belt to transmit higher loads at lower tension levels. Appropriate installation tension values can be obtained from Yonghang's design software, calculated using the design manual, or by consulting Yonghang's expert team.

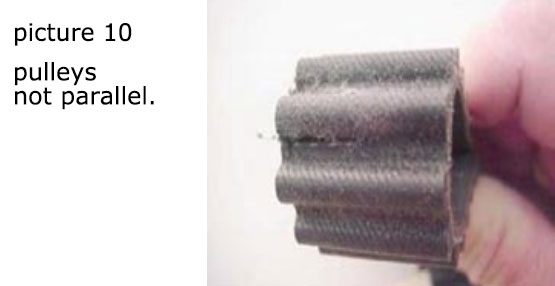

Misaligned pulleys: When the belt is in operation, the pulley shafts are angled relative to each other, or the pulley teeth exhibit taper issues during manufacturing. This results in uneven compression between the belt teeth due to the non-uniform load applied to the belt. Belt failure often initiates as a crack at the tooth root or along the side of the belt subjected to maximum tension, propagating across the entire belt width until the teeth shear off. Due to high tensile forces, the side experiencing severe compression may also exhibit significant wear, and the belt may climb or roll toward the pulley flange. Figure 10 illustrates severe wear on one side of the belt caused by high tensile forces.

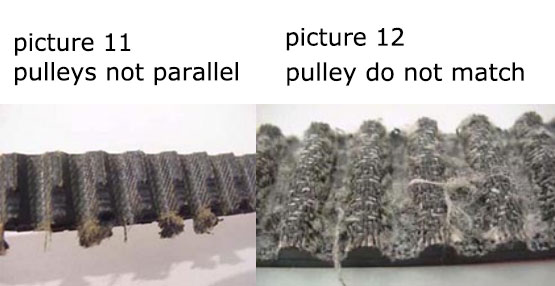

When a belt runs on non-parallel pulleys with sidewalls, severe wear occurs on both sides if the belt is squeezed between two opposing sidewalls. In such cases, the belt may tear from the root of the teeth or split along both sides. This tearing eventually propagates across the entire belt, leading to shear failure of the teeth.

When a belt runs on one pulley with flanges and another pulley without flanges, and the pulleys are not parallel, the belt will partially shift toward the pulley without flanges. This portion of the belt on the flangeless pulley will bear the entire load and may develop a concentrated wear area after running for a period of time. Figure 11 illustrates concentrated wear across most of the tooth surface, with no wear elsewhere. Root cracks may form beneath the worn area. Belt strength failure or tooth surface fatigue will ultimately cause premature belt failure.

Pulley Imbalance or mismatch: Whether caused by substandard pulley manufacturing or excessive wear, premature belt failure is often difficult to identify. This is partly because when a belt fails, few people meticulously inspect the pulleys, often attributing the issue solely to the timing belt itself. When a timing belt runs on a dimensionally flawed pulley, its teeth exhibit significant wear on the sides, while the belt's side fabric develops a fuzzy, frayed or flaked appearance, as shown in Figure 12.

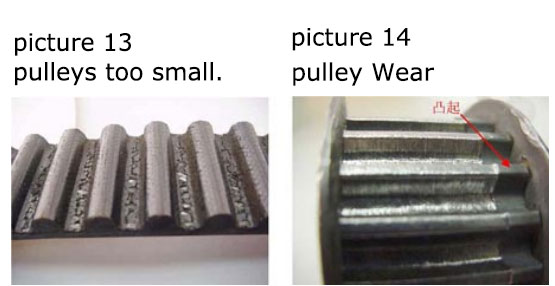

When toothed belts (HTD, GT2) operate in pulley systems with excessively small diameters, they may suffer extensive splitting and tensile failure, as shown in Figure 13. Trapezoidal-toothed belts (XL, L, H, T5, T10, T20) typically exhibit root cracks or tooth shearing, though tensile failure is relatively uncommon.

Excessive tension may cause increased pulley wear. On belts that have been in operation for extended periods, the tooth surfaces or canvas may sometimes be completely worn away, indicating that pulley wear has also occurred. Once a belt wears down, its core wire comes into contact with the pulley, leading to wear on the outer circumferential groove of the pulley. A raised ridge on the pulley's tooth crest is a sign of pulley wear, as shown in Figure 14. Caution: Abraded surfaces are extremely sharp. Use a screwdriver to feel for them to avoid cutting your hands. In such cases, the pulley should be replaced.

Pulley wear occurs most rapidly in corrosive atmospheres. Severely worn pulleys typically exhibit groove wear and a reduction in the machined outer diameter. Pulley wear leading to belt failure is characterized by polished damage to the belt's tooth base and localized dimensional deformation in the tooth area. Hard chrome-plated pulleys can extend their service life in corrosive atmospheres. Additionally, if a newly replaced belt exhibits shorter lifespan than its predecessor, carefully inspect the pulley for excessive wear.

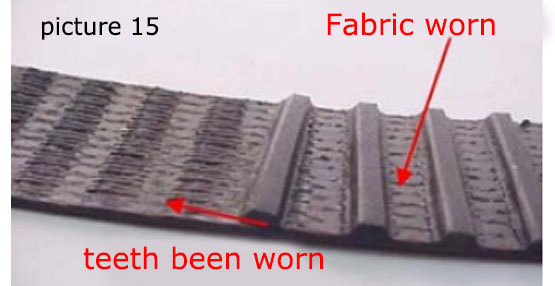

Pulley Runout: When a belt operates within a pulley system exhibiting radial runout, the belt tension fluctuates periodically as the pulley rotates. The greater the runout, the higher the peak tension rises. This effect causes the tooth base to appear crushed, as shown in Figure 15. The crushed belt body may resemble damage caused by excessive tension in belts running on undersized pulleys. Extreme periodic tension variations often lead to tooth edge tearing or elongation failure of the belt.

When installing pulleys onto tapered bushings, or after re-boring the smallest pulley bore, runout often occurs. Detailed instructions on standard installation procedures and ensuring proper shaft-bore fit are provided in Yonghang's relevant design manuals.

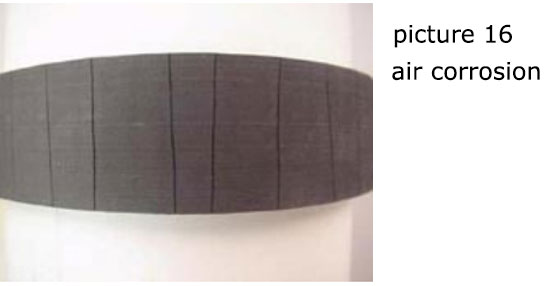

Corrosive Atmospheres: When belts operate in corrosive air environments—such as foundry mixers, iron ore processing equipment, or phosphate mining conveyors—the tooth flanks and tooth base height wear down, often leaving polished areas in the affected zones. Figure 16 shows a worn Power Strong GT2 belt in a highly corrosive environment. Pulleys typically wear faster in corrosive air, so both pulleys and belts should be replaced together. To extend belt and pulley life, install a sealed cover pressurized with clean air to prevent contamination from corrosive dust particles.

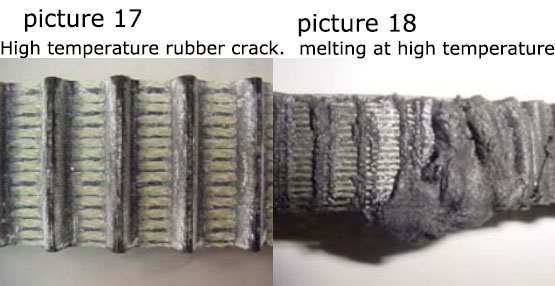

This hardening, combined with bending during operation, causes cracking along the belt's back. These cracks run parallel to the teeth direction and frequently occur at the center of the teeth, as shown in Figure 17. Shear forces at the teeth can also lead to tensile failure of the belt.

High-temperature-resistant rubber belt structures are suitable for applications demanding such environments. These specialized belt designs enhance service life.

To determine whether specialized high-temperature-resistant belts can improve performance in specific applications, please contact Yonghang's sales representatives.

Chemical Degradation: The failure of rubber belts exposed to volatile organic solvents and ozone resembles that observed under high-temperature conditions. The rubber components harden, leading to cracking on the belt's back surface. However, the cracking patterns are inconsistent because the hardening of the rubber structure occurs predominantly near the belt's surface. This can result in both longitudinal and transverse cracking, potentially forming a wide variety of shapes.

Figure 18 shows the high-temperature melting of the GT2 PU timing belt.

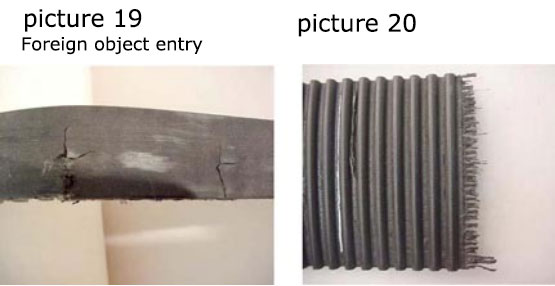

Foreign Object Ingestion: When foreign objects enter between the pulley and belt, they cause damage to both the belt teeth and core strands. Core strands typically break internally (as shown in Figure 19) or fail shortly thereafter due to excessive bending (as shown in Figure 20). Partial core wire breakage significantly reduces the belt's tensile strength. This also leads to a marked decrease in belt lifespan. If a timing belt is found damaged, it should be replaced, and the pulleys should be inspected. Any damaged pulleys should also be replaced promptly.

By systematically understanding these fault patterns and their causes, the failure rate of the timing belt can be effectively reduced, thereby enhancing the reliability and service life of the belts. Hope this can be of help to youare currently using the timing belt

I am Lucy, the author of this article. If you have any requirements related to synchronous belts, please send me an inquiry.

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

Recommended for you

no data

Get in touch with us

Useful Links

Products

Contact Details

Add:

4th Floor, Building B8, Chuangbao Creative Park, Federal Industrial Zone, West Yushan Road, Panyu District, Guangzhou, China. 511400

Tel: +86 134 1810 3085

E-mail: sales@yhbelt.com

Copyright © 2026 Guangzhou Yonghang Transmission Belt Co., Ltd. - www.yhbelt.com All Rights Reserved. | Sitemap | Privacy Policy