Variable speed belt manufacturers in China | Yonghang

Variable Speed V-Belt: This is a raw edge cogged v-belt with a wider cross-section than classical belts. There are two types: full coverage with fabric and edge cutting.They are designed to be used with variable speed pulleys. Their section can be made into standard or non-standard sizes.Made from chloroprene rubber (Neoprene) or EPDM.Its unique rubber fiber properties ensure it has both high lateral rigidity and longitudinal flexibility, offering high load-carrying capacity and a long service life.Cast teeth reduce heat accumulation or stress concentration, thereby extending the belt's lifespan. The smooth running structure ensures minimal variation even at high speeds. It complies with RMA oil-resistant and heat-resistant standards.The variable speed belt is available in RMA and ISO standards.

Product Introduction

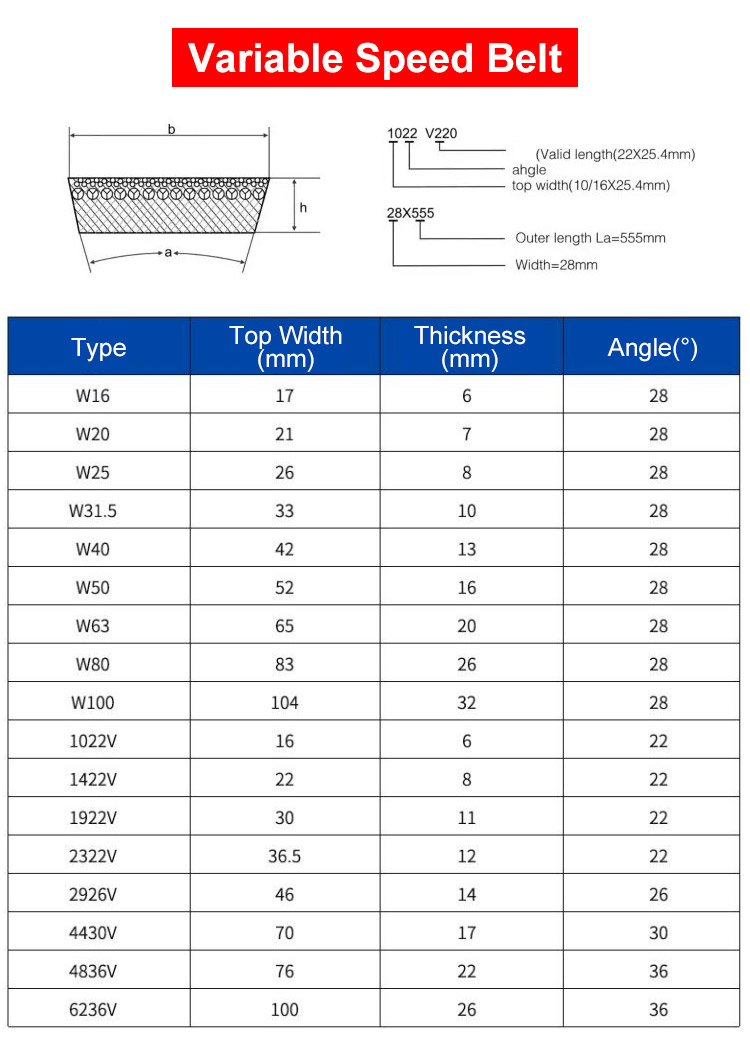

Products Presentation/Parameters Product Variable Speed V-Belt NO. Project Result 1 specifications W16 W20 W25 W31.5 W40 W50 W63 W80 W100 1022V 1422V 1922V 2322V 2926V 4430V 4836V 6236V 2 EPDM Working temperature ﹣60°C to —135°C 3 Length Scope(mm) 447-3150mm 4 Width Scope(mm) 17-100mm 5 Thickness Scope(mm) 6-26mm 6 Material EPDM/CR 7 Hardness 65 A 8 Wire core Aramid

| Products Presentation/Parameters | ||

| Product | Variable Speed V-Belt | |

| NO. | Project | Result |

| 1 | specifications | W16 W20 W25 W31.5 W40 W50 W63 W80 W100 1022V 1422V 1922V 2322V 2926V 4430V 4836V 6236V |

| 2 | EPDM Working temperature | ﹣60°C to —135°C |

| 3 | Length Scope(mm) | 447-3150mm |

| 4 | Width Scope(mm) | 17-100mm |

| 5 | Thickness Scope(mm) | 6-26mm |

| 6 | Material | EPDM/CR |

| 7 | Hardness | 65 A |

| 8 | Wire core | Aramid |

Variable Speed V-Belt Core Function: Continuously Variable Transmission (CVT)

This is the fundamental difference between it and ordinary V-belts or timing belts.

By adjusting the effective working diameter of the two pulleys (typically tapered pulleys with adjustable groove widths), the output shaft speed can be continuously and smoothly varied within the designed range without stopping the machine.This achieves continuously variable transmission.

Typical Structure:

Cross-sectional Shape: Typically wedge-shaped or multi-wedge-shaped, similar to standard V-belts or multi-V-belts. This allows it to fit well into the V-shaped grooves of tapered pulleys, providing high friction and lateral stability.

Tooth design: Many modern continuously variable belts (especially those used in high-demand applications such as automotive CVTs) feature a special tooth design on the inner side of the belt (the side in contact with the pulley groove).

Function:

Improves flexibility, allowing the belt to bend more smoothly over varying wheel diameters.

Reduces bending stress, extending service life.

Assists in heat dissipation.

In certain designs, the tooth profile also provides some meshing action, improving transmission efficiency and slip resistance (though the primary driving force remains friction).

Materials:

High-strength synthetic rubber (such as neoprene) is typically used as the base material to provide elasticity and friction.

The internal tensile layer uses high-strength fibers (such as polyester, aramid, or steel wire) to withstand primary tensile forces.

The outer layer may have wear-resistant and heat-resistant coatings.

What is the difference between chloroprene rubber and EPDM rubber?

CR: Operating temperature range: -20°C to 100°C. Due to its polar nature, it exhibits excellent resistance to non-polar solvents such as mineral oil, fuel oil, and aliphatic hydrocarbons. It has better oil resistance than most general-purpose rubbers (such as NR, SBR), but not as good as specialized oil-resistant rubbers (such as NBR, FKM). It has poor resistance to polar solvents (such as ketones, esters). The raw material cost is slightly higher than EPDM, but it has a shorter vulcanization time, though the raw rubber has poor storage stability.

EPDM: Operating temperature range: -60°C to 135°C. It exhibits excellent resistance to polar solvents (such as alcohols, ketones, esters, and certain refrigerants) as well as water, hot water, steam, detergents, and acid-base solutions. It possesses outstanding weather resistance, ozone resistance, and heat aging resistance, making it one of the best among known rubbers. Its highly saturated main chain structure provides exceptional resistance to UV radiation, ozone, and oxidative degradation. This is one of EPDM's most notable advantages. The raw material cost is slightly lower than CR, but the vulcanization speed is slower. However, it has excellent raw rubber storage stability.

Conclusion

If you need weather resistance, ozone resistance, heat resistance, water/steam/polar chemical resistance, insulation, low-temperature performance, and low cost, choose EPDM.

Main applications:

Industrial equipment: Machine tools requiring speed adjustment (such as drilling machines, lathes, milling machines), fans, pumps, conveying equipment, printing machinery, textile machinery, etc.

Automobiles: The core transmission component of continuously variable transmissions (CVTs), enabling smooth acceleration and good fuel economy. CVTs in automobiles typically use metal belts or chains, which are more advanced and durable forms, but the basic principle (changing the effective diameter of the pulleys to achieve speed variation) remains similar.

Agricultural machinery: Certain transmissions in harvesters and tractors.

Home appliances: Some appliances requiring speed regulation (though motor-based speed control is now more common).

Advantages:

Stepless Speed Control: Enables smooth, continuous speed changes.

Relatively Simple Structure: More compact than gearboxes.

Overload Protection: Slippage can prevent equipment damage to a certain extent (but excessive slippage will damage the belt).

Vibration Damping: Rubber material can absorb certain vibrations and impacts.

Smooth and Quiet Operation: (Under good conditions).

Limitations/Considerations:

Efficiency: Typically lower than gear drives or synchronous belt drives due to sliding friction losses (though tooth design reduces slippage).

Speed/Power Limitations: Limited application at extremely high speeds or very high power levels.

Maintenance: Requires regular tension checks; belts wear out and need replacement.

Accuracy: Speed control accuracy is inferior to electrical speed control methods such as servo motors.

Alignment requirements: Belt pulleys require proper alignment during installation.

Environment: Harsh environments such as oil contamination or high temperatures can significantly short

Company Advantages

Frequently Asked Questions about v belt supplier

Contact Details