1. Locate and Decipher the Part Number

The most reliable method is to find the manufacturer's part number printed on the belt's back. This alphanumeric code contains all the specifications you need.

Example 1 (Metric): A code like 25 T5 510 often deciphers as:

25:Belt width in millimeters (25mm)

T5: Tooth profile (Trapezoidal) and pitch (5mm between teeth

510: The effective length, or pitch length, of the belt in millimeters (510mm)

Part No.8M-1000-25

8M:Circle-arc tooth profile and pitch (8mm between teeth)

1000:The effective length, or pitch length, of the belt in millimeters 1000mm

25:Belt width in millimeters (25mm)

Example 2 (Inch): A belt marked 750H100 typically means:

750: The nominal length in inches (75.0 inches)

H:The tooth profile (Trapezoidal) and pitch (1/2" or 12.7mm)

100:The nominal width code (1" or 25.4mm)

The part numbers here, except for the timing belt in imperial units, are all expressed in mm. However, there are also imperial timing belts such as:

Part No. L-2238.375-25 typically means:

L:The tooth profile (Trapezoidal) and pitch (3/8" or 9.525mm)

2238.375:The effective length, or pitch length, of the belt in millimeters(2238.375mm) nominal length in inches (88 inches)

25:The width is 25mm

PU timing belts also feature several specialized models beyond standard rubber timing belts, such as self-tracking timing belts like TK, ATK, and BATK. These are still denoted in millimeters, typically with an additional guide bar dimension specified—for example, ATK10K13*4560*50.

typically means:

ATK10:The tooth profile (AT) and pitch (10mm) But it comes with guide bar.

K13: guide bar bottom width 13mm,guide bar height by the base:width13mm and height 8mm.

4560: pitch length, of the belt in millimeters(4560mm)

50:Belt width in millimeters (50mm)

If the part number is worn off, you will need to take physical measurements.

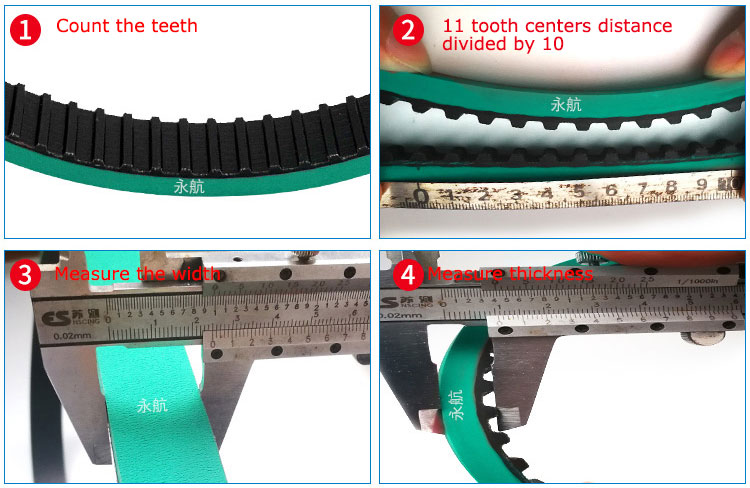

2. Measure the Critical Dimensions

Precise measurement is key. You will need a caliper for accuracy.

1.1. Recognize Common Tooth Profiles

Identify the Tooth Profile and Pitch (P): First, determine if the teeth are trapezoidal (T-type, imperial timing belts) or curved (e.g., HTD,STD, RPP). Then, measure the pitch (P)—the distance between the center of one tooth and the center of the next . Common metric trapezoidal pitches include T2.5(2.5mm)T5 (5mm)and T10 (10mm)T20(20mm), while common inch-based profiles includeMXL(2.032mm)L(9.525mm) H (12.7mm) and XL (5.08mm)XH(22.225)

The tooth profile determines the belt's load-carrying capacity and noise levels.

Trapezoidal (Inch & Metric): Includes MXL, XL, L, H (inch) and T5, T10 (metric). These are general-purpose profiles but are being superseded by curvilinear profiles for high-power applications.

Curvilinear (High-Torque Drive): These profiles, such as HTD (with a rounded tooth) and the more advanced STD and RPP, provide superior load distribution and are less prone to tooth jump-out under heavy loads.

1.2. Identify Pitch Distinguish Between Materials: Rubber vs. PU

The pitch of rubber timing belts lacks a recess at its center, making measurement errors common. To minimize such errors, measure multiple teeth—for example, divide the pitch value obtained from 2-3 teeth by the total number of teeth. This approach yields a more accurate result. Use this method when distinguishing between XL (5.08mm) and T5 (5mm) belts.

![rubber timing belts measure]()

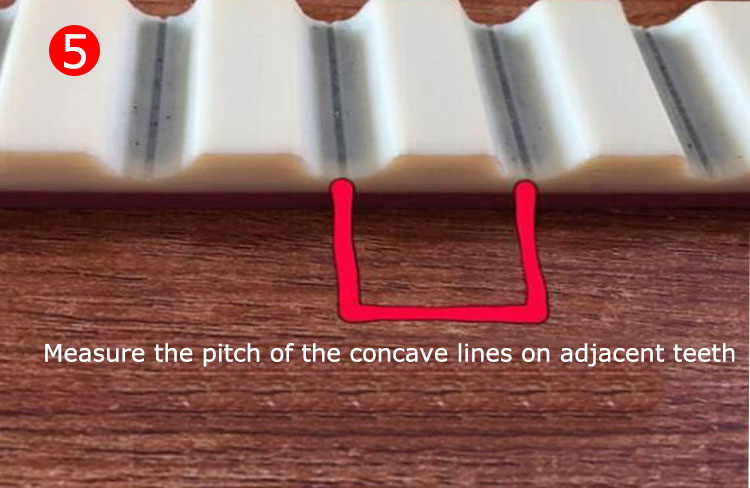

· PU timing belts,Measuring the pitch is very simple. During production, PU timing belts are manufactured using extrusion and molds, both of which incorporate groove lines. When measuring pitch, the position of the groove lines between adjacent teeth allows for accurate pitch measurement. If differentiation remains unclear—for example, between T10 (10mm) and L (9.525mm)—the belt's thickness, tooth width, and other factors can be used to determine the correct pitch.

![pu timing belts measure]()

3· Identify the length and Width

3.1Count the Number of Teeth (Z): Count all the teeth on the belt. The pitch length can be calculated as Pitch Length (L) = Number of Teeth (Z) × Pitch (P).

3.2· Measure the Belt Width: Measure the width of the belt across the top (toothed) surface

By systematically following these steps—checking the part number, taking precise measurements, and identifying the material and profile—you can confidently select the correct timing belt for any application. When in doubt, consult with a Yonghang timing belt technical datasheet or Yonghang Expert Team to verify your findings.