Today, Yonghangbelt summarizes the common problems of folder gluer belts in packaging printing and the corresponding solution suggestions.

12 Years Transmission Belts Coating Customized Factory.

Yonghangbelt summarizes the common problems of gluing machine belts in packaging printing|Yong Hang

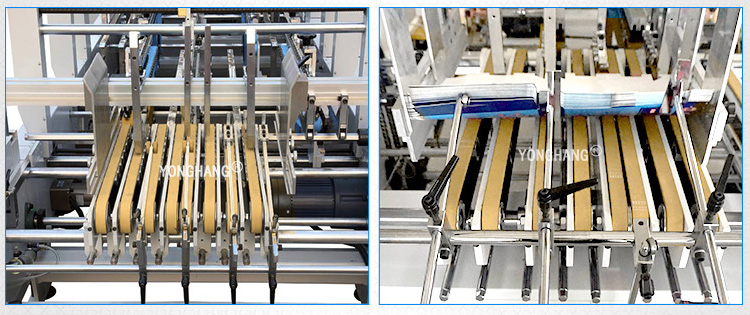

With the development trend of diversification of paper packaging container products becoming more and more obvious in recent years, the folder gluer belts as an important transmission part in the packaging printing gluing machine equipment not only improves the production efficiency but also improves the molding quality!

1. Gluing is not firm

You can check the amount of glue applied, if it is on the UV varnish carton, you need to install a grinding device on the equipment, the bonding part of the hair can be properly bonded.

2. Printed surface scratches

If folding paper using wire, especially small boxes are not recommended to use the belt crease, the wire is easy to scratch the surface.

3. Paper going in the wrong direction

This requires adjustment of the placement of the paper blocking gauge and the pressure balance of each department.

This is a comprehensive problem that needs attention from the die-cutting stage, but if the equipment can be specially designed in the folding section, such as the angle of the knife row folding paper, the problem can be easily solved by lengthening the length from the feeding section to the folding section, which makes the paper walking a gradual process and makes the box shape more regular.

5. The belt is easy to fall off

It may be caused by belt flare, runaway or belt slack, then the cause should be identified and dealt with in a timely manner, such as belt runaway can be solved by adjusting the roller or adjusting the roller group; belt slack can be solved by adjusting the active and driven pulleys or adding tensioning pulleys.

6. Belt breakage

Belt breakage can be caused by fast speed and shifting speed, uneven force due to too long or too short belt, large load, aging of belt material for long term use, etc.; belt should be checked and replaced regularly, speed and shifting speed should be adjusted appropriately, and belt tension should be adjusted appropriately.

Please contact us direct for more information regarding your specific requirements.

Whatapp&wechat:+ 0086 13725100582

Email :sales@yhbelt.com

Contact Details