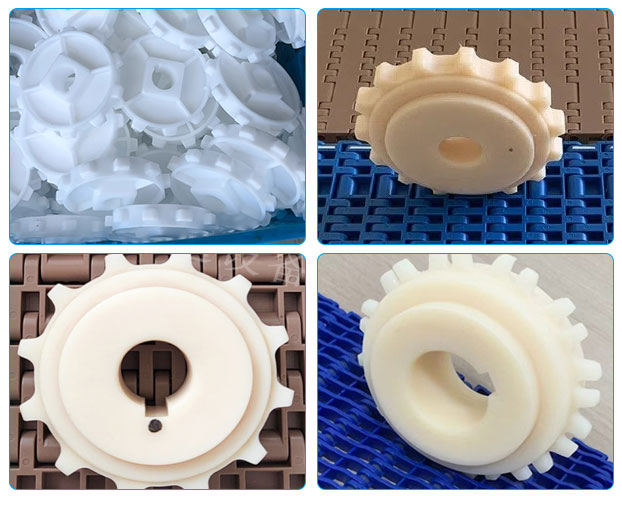

Injection-molded sprocket and machined sprocket are two common types of industrial manufacturing products, exhibiting significant differences in manufacturing processes, costs, and application scenarios.

12 Years Transmission Belts Coating Customized Factory.

wath is different molded sprocket and machined sprocket?

Injection-molded sprocket and machined sprocket are two common types of industrial manufacturing products, exhibiting significant differences in manufacturing processes, costs, and application scenarios.

molded sprocket:This process is well-suited for high-volume production, as molds can be reused, enabling high production efficiency.

Machined parts, on the other hand, are created by removing excess material from raw stock through mechanical processes like cutting, grinding, and drilling to achieve the desired shape and dimensions. This method offers high flexibility and is ideal for small batches or customized production. Machined parts, requiring no molds, involve lower initial investment but higher unit costs, particularly at higher production volumes.

Application scenarios, injection-molded parts are widely used in automotive, electronics, and home appliance industries, where large-batch part requirements exist alongside demands for appearance and dimensional accuracy. Machined parts are more prevalent in aerospace, medical devices, and mold manufacturing, where precision, material properties, and customization are paramount. Additionally, material selection differs between injection-molded and machined parts. Injection molding typically employs plastics like polypropylene and polyethylene, which offer excellent formability and cost-effectiveness. Machined parts, however, can utilize various materials including metals, plastics, and composites, selected based on specific requirements.

In terms of production cycles, injection-molded parts have relatively shorter lead times since production accelerates once the mold is completed. Machined parts, however, require longer production cycles as each component undergoes individual processing, often involving multiple machining stages. In summary, injection-molded and machined parts each have distinct advantages and disadvantages in manufacturing processes, cost, application scenarios, material selection, and production cycles.

The choice between these manufacturing methods requires comprehensive consideration of specific product requirements, production volume, and cost budgets. We currently offer a range of injection-molded and machined parts in various materials to meet the needs of different industries and applications. Please contact us for more information.

If you want to know more, please visit our website:www.yhbelt.com,Yonghang transmission belt company has been focusing on transmission belt and pulleys research and development and production for 12 years, the use of factory direct sales mode, with 10000m² plant, more than 8000 sets of molds, more than 50 advanced equipment, support customization, and provide 12 months of free after-sales service and technical support!

Wechat&Whatapp:86+134 1810 3085

Emali:sales@yhbelt.com

Contact Details