The Yonghangbelt indicates that the gluing machine is mainly composed of six parts, namely the feeding part, the pre-folding part, the gluing part, the folding part, the pressing part and the receiving part, as follows.

From the internal structure of the gluing machine, you can see the importance of the folder belt!|Yonghangbelt

2022-08-24

×

The Yonghangbelt indicates that the gluing machine is mainly composed of six parts, namely the feeding part, the pre-folding part, the gluing part, the folding part, the pressing part and the receiving part, as follows.

1. Feeding part: the material will be placed on the paper pile. The material is separated one by one and passed to the pre-folding part through the paper belt of the gluing machine, which is completed by the friction drive of the upper and lower paper belts.

2. Pre-folding section: the die-cutting creasing line is used to bend the carton sheet by 120 or 150 and then return it to its original shape through the guide bar to obtain the pre-folding effect. For a simple folded carton, the pre-folding is usually done at the third and first crease line. This pre-folding is very necessary for the automatic filling of the folded carton, which can be easily opened after gluing and is easy to achieve automatic filling. This pre-folding can be done by means of belts and guide rods. For some special folds, different angles and folding rods must be used to complete the pre-folding of folded cartons with a locked bottom, such as hooks for the bottom.

3. Gluing part: It consists of a glue hopper and an impeller. The impeller rotates to bring out the glue from the glue hopper and then applies the glue from the impeller to the flap to form a tape to complete the coating. The amount of glue can be controlled by the thickness of the impeller, which is usually 3mm, and the way of applying glue on the bottom is also the way of applying glue in the current equipment.

4. This part of the fold: through the upper and lower transfer belt using the second and fourth crease line on the carton piece to complete the folding carton together, so that the bonding flap and sticky wall plate on the lap, to complete the initial work of bonding. This part should pay special attention to the parallel and alignment of the crease parts to prevent sticky slant and dew glue.

5. The part of the press fold: bonding flaps and sticky wall panels in the paper belt and auxiliary equipment under pressure to complete the bonding process, and smoothly transported to the next part to complete the bonding.

6. Receiving section: consists of a long stand or vertical stand with a widened conveyor belt. The glued carton is clamped in the upper and lower conveyor belt to obtain a certain pressure and form a solid bonding layer. Because the curing of the adhesive takes some time, the bonding is more secure with the aid of pressure.

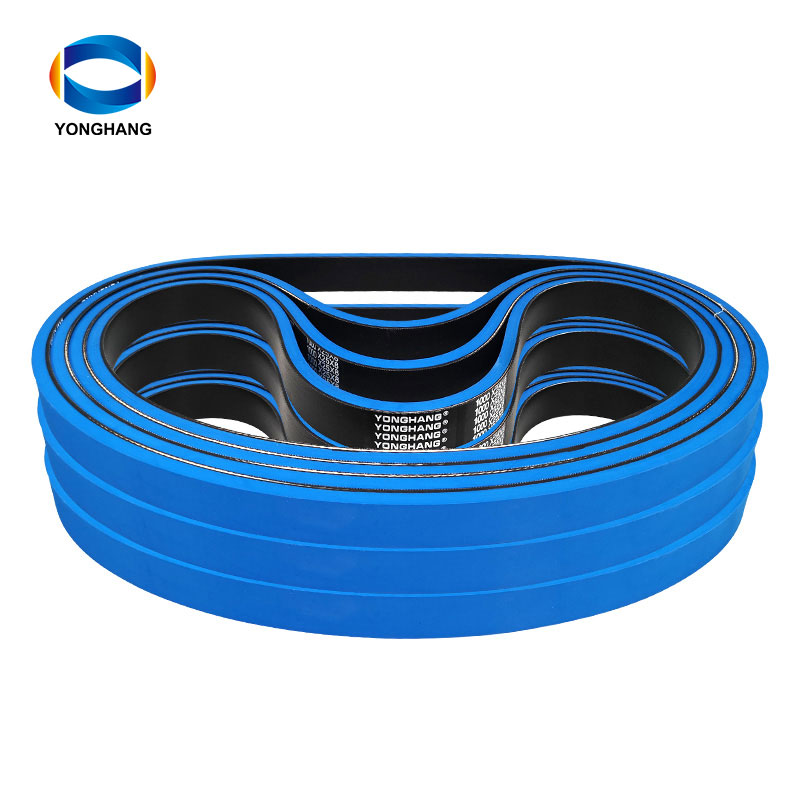

From the above working principle of the box gluer, it can be seen that the folder belt is an essential conveying part. The Yonghangbelt's folder belt adopts a mature mould with an integrated vulcanisation process, without any interface or gap, to ensure that it will not break longitudinally or delaminate during use. The belt body is made of imported raw rubber material, with special wear-resistant fibres added to make it more durable, with good performance of wear resistance, no slippage and no powder loss; and with high strength nylon core as the strong layer, with 35% increase in tensile strength, good dimensional stability and small elongation!

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13725100585

Email :sales@yhbelt.com

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

Recommended for you

no data

Get in touch with us

Useful Links

Products

Contact Details

Add:

4th Floor, Building B8, Chuangbao Creative Park, Federal Industrial Zone, West Yushan Road, Panyu District, Guangzhou, China. 511400

Tel: +86 134 1810 3085

E-mail: sales@yhbelt.com

Copyright © 2026 Guangzhou Yonghang Transmission Belt Co., Ltd. - www.yhbelt.com All Rights Reserved. | Sitemap | Privacy Policy