What is a plastic chain plate?What are the classifications of plastic chain plates?The transportation and storage methods of plastic chain plates?

Plastic Chain Belts Classification Transportation and Daily Maintenance

Introduction to Plastic Chain Belts

Plastic chain belts are primarily made from materials such as plastic steel (ACETAL), polypropylene (PP), polyethylene (PE), nylon (PA), and others. They represent a new type of conveyor belt offering significant advantages over traditional belts: high strength, resistance to acids, alkalis, and saltwater, wide temperature tolerance, excellent anti-adhesion properties, compatibility with side guides, high incline capability, easy cleaning, and simple maintenance. They are suitable for conveying in diverse environments, including pharmaceuticals, food processing, packaging, daily chemical products, automotive manufacturing, logistics, amusement facilities, transmission belts, and conveyor equipment.

Transportation and Daily Maintenance

1. During transportation and storage, keep the conveyor belt clean. Avoid direct sunlight or exposure to rain/snow. Prevent contact with acids, alkalis, oils, organic solvents, and similar substances. Store at least one meter away from heat-generating equipment.

2. Maintain warehouse temperatures between 18-40°C (64-104°F) during storage. Keep relative humidity between 50-80%.

3. During storage, products must be rolled without folding and rotated quarterly.

4. Conveyor belts of different types, specifications, or ply counts should not be joined together. Adhesive bonding is recommended for splicing.

5. Select conveyor belt type, structure, specification, and ply count based on operational conditions.

6. Conveyor belt operating speeds should generally not exceed 2.5 m/s. (Use it in accordance with the manufacturer's instructions.)For large-sized, highly abrasive materials and fixed-type discharge devices, lower speeds should be prioritized.

7. The relationship between the diameter of the conveyor's drive pulley and the fabric layers of the belt, the matching of drive and redirect pulleys, and the required trough angle of idlers should be selected reasonably according to the conveyor's design specifications.

8. Material feeding should follow the belt's running direction. Chutes should be used to minimize impact from falling material and reduce drop height. On the receiving section, shorten idler spacing and use cushioning idlers to prevent material leakage. Flexible, appropriately rigid baffles should be employed to prevent excessive hardness from damaging the belt surface.

Observe the following precautions during belt operation:

① Prevent material buildup on idlers that impedes rotation. Avoid material jams between drums and belts. Lubricate moving parts but avoid oil contamination on the conveyor belt.

② Avoid starting under load.

③ Correct belt misalignment promptly during operation.

④ Repair localized damage to the belt immediately to prevent further deterioration.

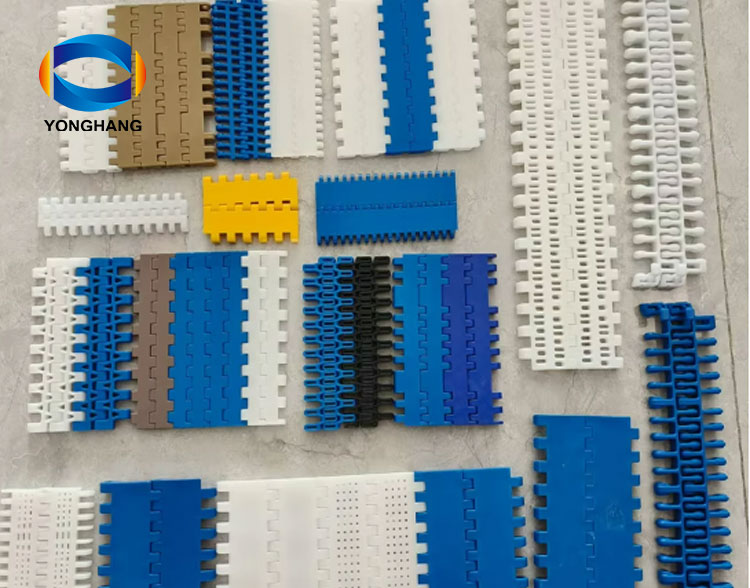

Classification

By Material: Polypropylene(PP), Polyoxymethylene (POM), Polyethylene(PE)

By Pitch: 8.4mm,9.5mm,12.5mm,12mm,12.7mm,14.5mm,15.2mm, 15.25mm,19.05mm, 19.5mm,25.4mm, 31.75mm, 32mm,27.2mm, 38.1mm, 50.8mm, 57.15mm

By environmental rating: Food-grade, Non-food-grade

By performance: High-temperature resistant, Oil-resistant, Abrasion-resistant, Acid/alkali corrosion-resistant

Q: Are you a trading company or manufacturer?

A: We are a manufacturer of modular belt, chains belt and conveyor components, with head office in Guangzhou, China, and three big factories located in Dongguan, Foshan and Jiangmen.

| Characteristics | POM | PP |

| Mechanical strength | High rigidity, high wear resistance | Medium strength, high toughness |

| Working temperature | ﹣40°-80°C(High temperature releases odors) | ﹣0℃-100℃ (brittle at low temperatures) |

| Chemical properties | Not tolerant of strong acids | Strong (acid and alkali resistant, solvent resistant) |

| Application | Heavy-duty conveying, precise transmission (automobile assembly line, logistics transportation (high wear + precision) choose POM) | Food processing, corrosive environment. For food factory baking lines (high temperature + hygiene),ChoosePP |

FAQ

Q: Are YONGHANG® products in accordance with FDA regulations and Rosh Directives?

A: Our standard materials (PP, POM, PE, PA) comply with the FDA regulations and Rosh Directives. A letter of assurance can be made available on demand.

Q: Can we use YONGHANG® Modular Conveyor Belt in corrosive environment?

A: YONGHANG® belts can be used in medium to severe abrasive applications, however, special product recommendations and conveyor design guidelines must be followed. More information, pls contact our online Customer Service or email to YONGHANG® Team.

Q: What is the temperature range for the belt material?

A: YONGHANG® belts offers various materials suitable for operation in temperatures ranging from -60°C to 400°C. Specific material should be chosen based on your operating temperature.

Q: What is the real meaning of the belt strength?

A: The belt strength is the maximum tension (per foot or meter of width) the belt can continuously run at.

Q: How long will it take me to get quotation?

A: You will always receive any requested quote by the end of the next working day at the latest, but often quotes are emailed to you before you hang up the phone

Contact Details