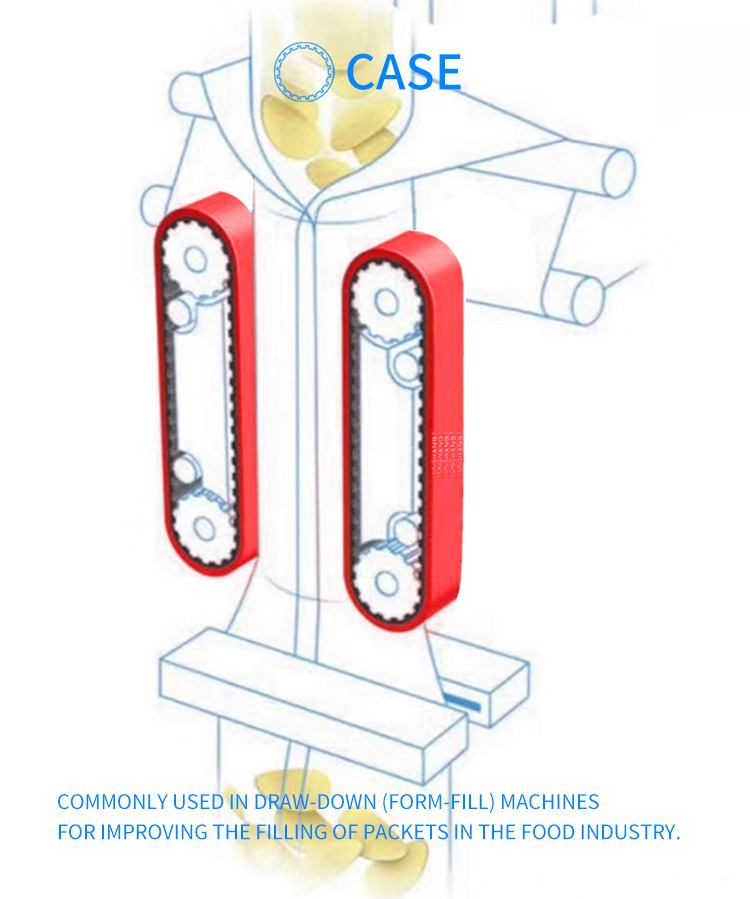

VACUUM TIMING BELTS are utilized in form fill machines within conveying and packaging lines used in food and packing facilities. The vertical form-fill-seal machine creates plastic bags out of a flat roll of plastic film while filling and sealing the bags with product at the same time. Then a pair of belts with the special grip coatings (usually in the vertical position for easier filling control), grip and draw down the bags. When the desired gross product weight is reached the filling stops, and a horizontal sealing bar seals the top of the bag and forms the bottom of the next bag. Because these belts are used vertically people also know them as VFFS draw down belts.

![How many hole patterns kind of VACUUM TIMING BELTS 1]()

These vacuum belts play a suction role in the process of pulling down, so it is necessary to punch various patterns of holes to achieve

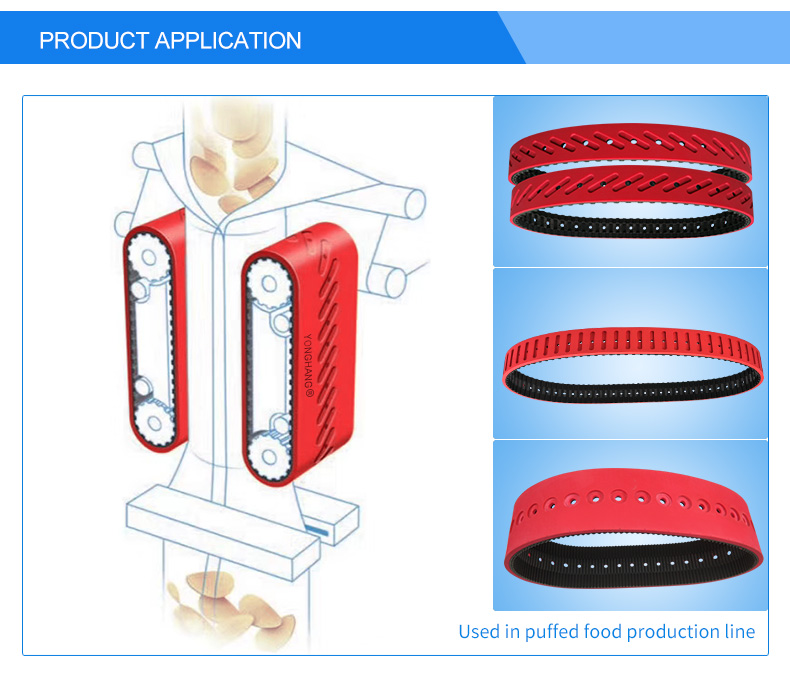

Fabrication: Includes perforation of holes – standard, countersunk, multi-depth in varying sizes and shapes, tooth removal – groove, slots, profiling, grinding, punching

![How many hole patterns kind of VACUUM TIMING BELTS 2]()

Yonghang supplies an extensive range of standard and custom made timing vacuum belts.

Hole patterns : such as round holes, square holes, plum holes, oval holes, water drop holes, countersunk holes,etc. A simple punching belt drawing.

![How many hole patterns kind of VACUUM TIMING BELTS 3]()

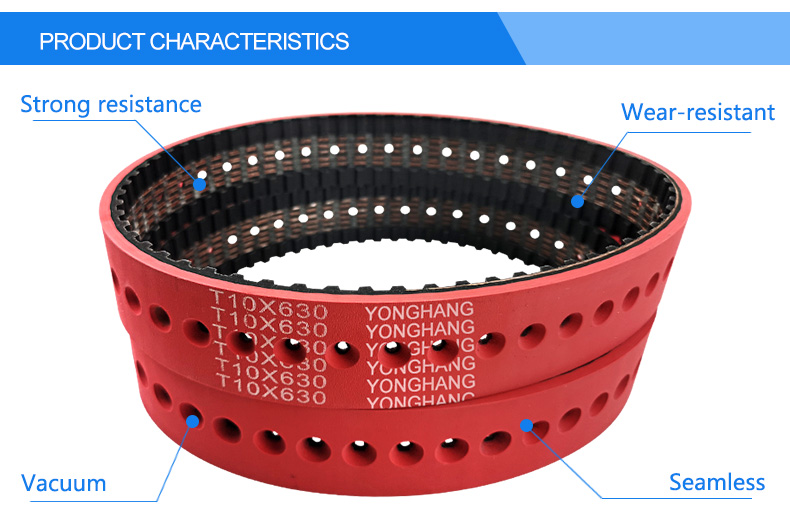

The following details relate to standard or most popular belt specifications.

If applicable, please contact us directly regarding specific requirements for different coatings, special fabrication or to discuss the possibility of any other technical changes.

Machine – Belt suitable for ROVEMA Belt Description

50T10-630

Timing Base Belt

NEOPRENE

Coating – Type / Colour

Natural Rubber

RED

Hardness: 40 ShA (Duro)

Fabrication Details

Tooth Removal:

15mm – Centre

Perforation:

42 Countersink Holes – 4/11mm DIA

![How many hole patterns kind of VACUUM TIMING BELTS 4]()

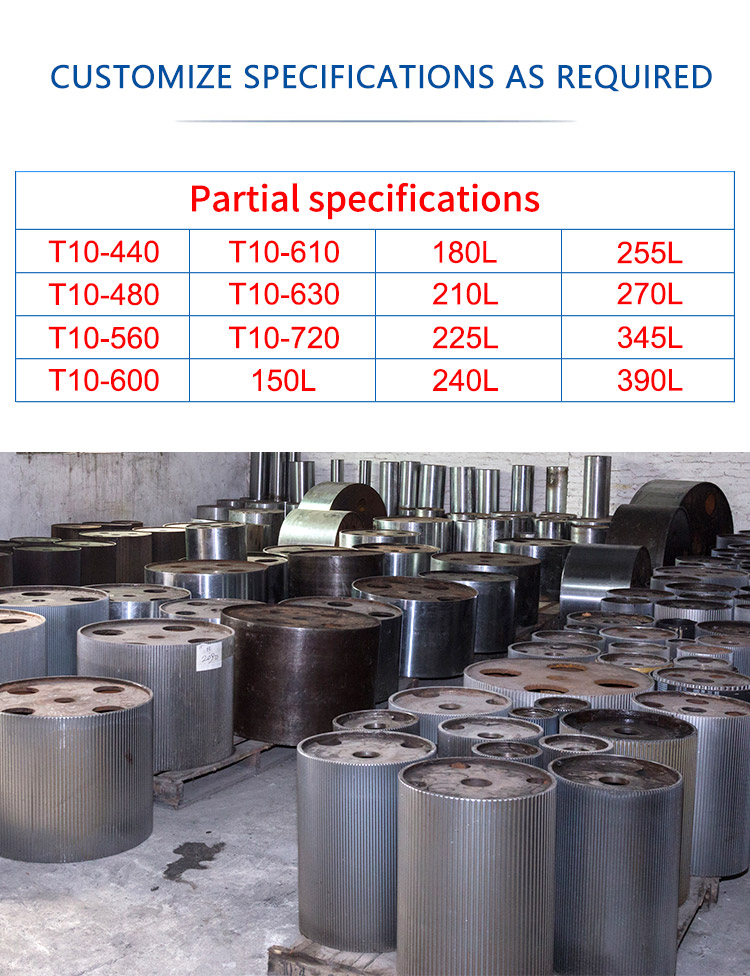

The majority of our fabricated belts are molded seamless truly endless (without a joint). Application of the truly endless belts in the production process greatly reduces many problems associated with spliced belts such as: uneven wear, breaks on the joint line, variation in the speed and movement of the belts. Elimination of spliced joints means that an even hardness is achieved resulting in an increased reliability, durability and longevity. A greater reduction in breakdowns and consequent down time are the major benefits of using our seamless belts.

Our range includes spliced belts – these are supplied if this option is preferred by our customer or if required due to specific application or the size of the belt.

Whatever your belting requirements might be, we are here to help you.

The following is not an exhaustive list of our products.

Please contact us direct for more information regarding your specific requirements.

![How many hole patterns kind of VACUUM TIMING BELTS 5]()