In the apparel industry, garment folding machines are a common type of high quality apparatus equipment. Since the introduction of garment folding machines, many garment industries have started to speed up production, shorten packaging times and at the same time reduce labour costs. Garment folding machines are able to quickly fold garments of different materials and qualities, and can be used to group these garment products into categories. When using the equipment, Yonghangbelt reminds everyone of the need for correct usage and the following matters of the polyamide belt.

12 Years Transmission Belts Coating Customized Factory.

Pay attention to 5 matters of polyamide belt when using the garment folding machine!|Yonghangbelt

2022-09-26

×

First, every day is to often check the sealing of the reducer surface and shaft end, such as oil leakage is serious, must identify the causes and take appropriate measures.

Second, every day after work often check the oil volume of the reducer. When the oil level is too low, that is, the little finger into the oil level plug hole, bending contact not oil, should add a comparable brand of lubricant.

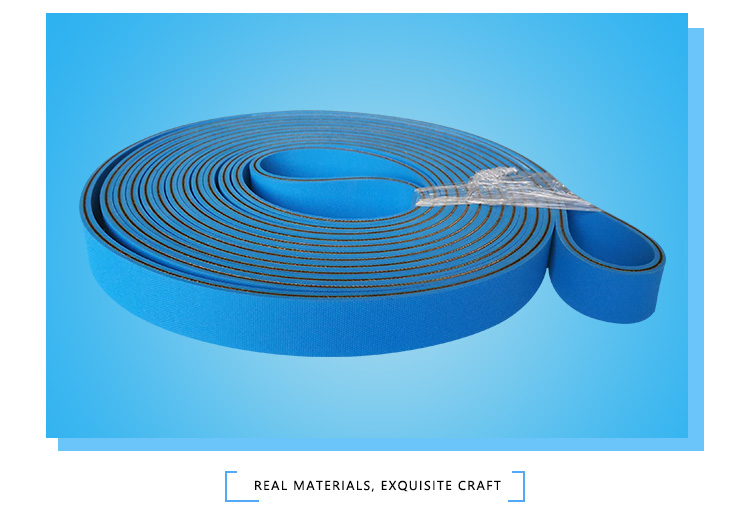

Third, clothing folding machine need to frequently check the wear and tear of the clothing folding machine polyamide belt, to maintain the appropriate initial tension, do not make the initial tension is too large. Note to keep the polyamide belt clean, avoid sunlight or rain and snow soaked, avoid contact with acids, alkalis, oils, organic solvents and other substances, 1 m away from the heating device. Clothing folding machine polyamide belt as an important part of the folding machine conveying, need to be more care!

Fourth, garment folding machine use to frequently check the sealing situation at both ends of the output shaft of the reducer to prevent oil leakage, tablecloth folding machine use process to keep the reducer clean.

Five, clothing folding machine in the rotation process is dependent on the reducer in the rotation, all reducer is the power source of the folding machine, the folding machine must be replaced after 300 runs of lubricating oil, the second time for 1000 hours, and later for every 2000 hours to replace.

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13418103085

Email :sales@yhbelt.com

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

Recommended for you

no data

Get in touch with us

Useful Links

Contact Details

Add:

4th Floor, Building B8, Chuangbao Creative Park, Federal Industrial Zone, West Yushan Road, Panyu District, Guangzhou, China. 511400

Tel: +86 134 1810 3085

E-mail: sales@yhbelt.com

Copyright © 2026 Guangzhou Yonghang Transmission Belt Co., Ltd. - www.yhbelt.com All Rights Reserved. | Sitemap | Privacy Policy

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service