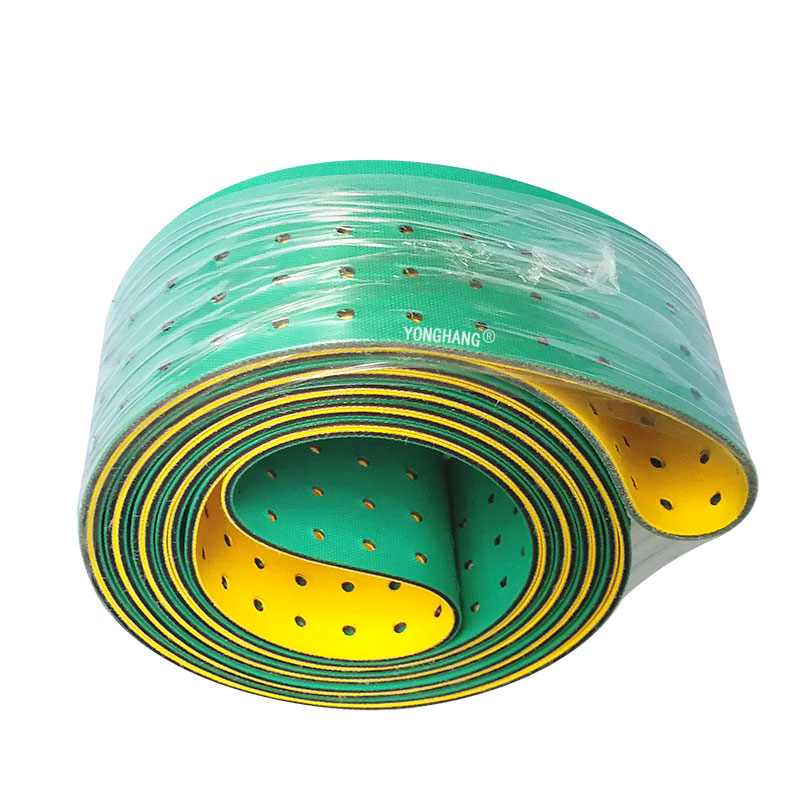

(1) As the middle core layer of the nylon flat belt core is on a flat surface, the adhesion between the side rubber and the belt core is small and the side rubber is easy to fall off, which resulting in delamination.

(2) As the width of the top and bottom layer of pressed edge glue is too large (20 mm), it is easy to expose the cloth on the side of the nylon flat belt, which leading to delamination.

(3) As the upper and lower top layers are curved in contact with the side rubber, it is easy to form a hollow edge leading to a split in the side rubber, which also easily leads to delamination.

(4) Due to the single specification of the side rubber, the nylon flat belt needs to be stretched for different thicknesses, which is not only labour-intensive, but also unstable in quality and leads to uneven belt width. It is easy to bring the side exposed cloth, side sponge lead to delamination.

To sum up, the single variety of side rubber and the unreasonable structure of the side rubber are the main reasons for delamination.

![What is the main reason for the delamination of nylon flat belt| Yonghangbelt 1]()

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13418103085

Email :sales@yhbelt.com

![What is the main reason for the delamination of nylon flat belt| Yonghangbelt 2]()