Haul off machine belt is widely used in TQD haul off machines, extruders and other types of traction equipment, I believe that we will encounter the phenomenon of belt slippage in the process of use, belt slippage is a common problem, so how to solve this problem?

12 Years Transmission Belts Coating Customized Factory.

Yonghang Talk About Five Solutions Of Haul Off Machine Belt slippage

2022-06-25

×

Today Yong Hang will introduce you to the five solutions of haul off machine belt slippage, hope it can help you well!

1.Increase the tensioning force (initial tension). Traction equipment in operation, the belt to be stretched, resulting in a decrease in traction, so according to the situation, the use of tensioning devices should also be properly tensioned belt, increase the tension of the belt to improve traction. Of course, in the process of installing or replacing the belt, the belt length must be controlled, and the tensioning device can only be adjusted within a certain range.

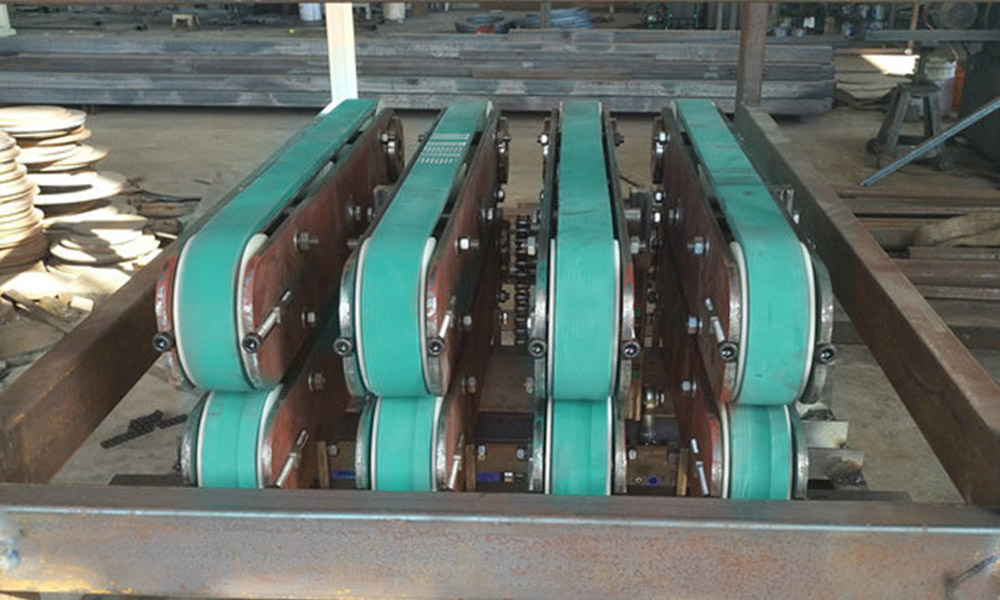

2.Increase the coefficient of friction. Specific measure is protecting the drive pulley, covered with nylon or rubber padding, increase the coefficient of friction.

3.Increase the angle of the housing. For the slope, poor working conditions and traction working environment, consider using double drum drive to increase the enclosure angle.

4.The friction between the transmission drum and the tractor belt is not enough to cause slippage. The main reason is most of the belt with water or wet environment. The solution is to add some rosin on the roller end. But be careful not to add by hand, but should be blown into the blower equipment to avoid accidents.

5.Correct control of roller distance. The distance between rollers or the number of rollers should match with the whole production line. When the slope and load increase, the drop of the tractor belt will increase and the number of rollers needs to be increased. On the contrary, it will decrease. Sometimes belt slippage may be caused by one aspect, but more often it is a combination of two or more of the above.

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :sales@yhbelt.com

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

Recommended for you

no data

Get in touch with us

Useful Links

Contact Details

Add:

4th Floor, Building B8, Chuangbao Creative Park, Federal Industrial Zone, West Yushan Road, Panyu District, Guangzhou, China. 511400

Tel: +86 134 1810 3085

E-mail: sales@yhbelt.com

Copyright © 2026 Guangzhou Yonghang Transmission Belt Co., Ltd. - www.yhbelt.com All Rights Reserved. | Sitemap | Privacy Policy

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service