YONGHANG Cleats can be attached to timing belts at any time using various processes. These include welding, chemical bonding and mechanical connections. The in-house injection moulding process incorporated in the production cycle ensures good product availability.

12 Years Transmission Belts Coating Customized Factory.

How many types of PU timing belt with Cleats ?

2022-09-28

×

YONGHANG Cleats can be attached to timing belts at any time using various processes. These include welding, chemical bonding and mechanical connections. The in-house injection moulding process incorporated in the production cycle ensures good product availability.

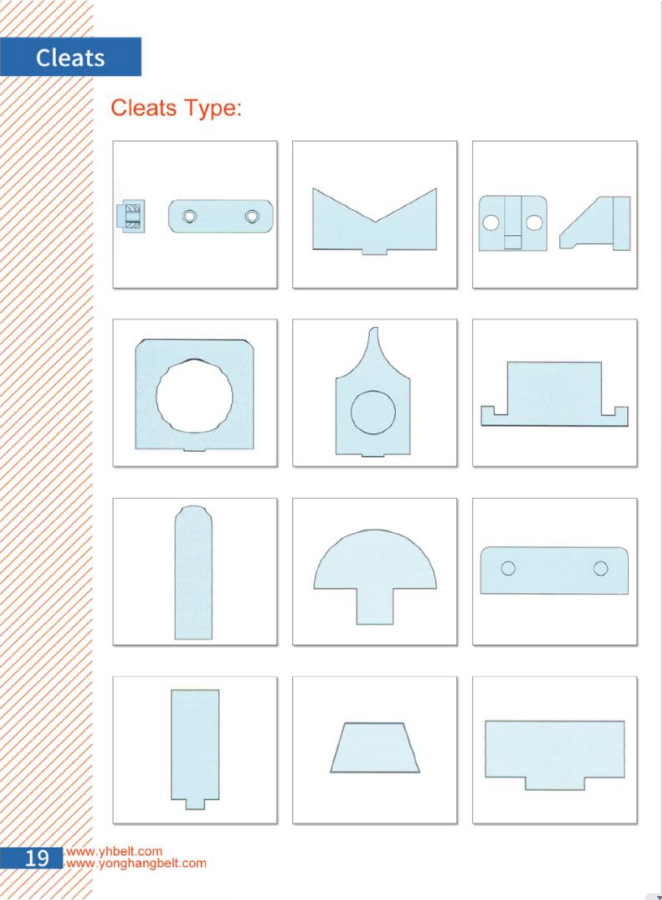

In contrast to coatings that rely on a frictional connection, cleats allow for positive-fit traction of goods on conveyors. They can also, for example:

· Convey and, if necessary, align products longitudinally and/or laterally

· Position them on the conveyor belt

· Separate products

· Enable high accelerations and/or speeds

· Synchronise the conveyed goods with the base belt

If none of these cleats fits your requirements, a suitable cleat can be made

· by mechanically processing an existing cleat

· with a custom-made injection mould.

The use of an injection mould is ideal for producing medium quantities or more of simple cleat shapes and small quantities of more complex cleat shapes. This can be done in the company’s own tool shop.

Yonghang transmission belt company has been focusing on Timing belts with cleats research and development and production for 10 years, the use of factory direct sales mode, with 10000+m2 plant, more than 8000 sets of molds, more than 50 advanced equipment, support customization, and provide 12 months of free after-sales service and technical support!

Please contact us direct for more information regarding your specific requirements.

URL:http://www.yhbelt.com

Whatapp&wechat:+ 0086134 1810 3085

Email :sales@yhbelt.com

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

Recommended for you

no data

Get in touch with us

Useful Links

Contact Details

Add:

4th Floor, Building B8, Chuangbao Creative Park, Federal Industrial Zone, West Yushan Road, Panyu District, Guangzhou, China. 511400

Tel: +86 134 1810 3085

E-mail: sales@yhbelt.com

Copyright © 2026 Guangzhou Yonghang Transmission Belt Co., Ltd. - www.yhbelt.com All Rights Reserved. | Sitemap | Privacy Policy

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service