1. What are the main factors affecting the belt of the box gluer?

2. How to clean and maintain the belt of the gluer?

12 Years Transmission Belts Coating Customized Factory.

1. What are the main factors affecting the belt of the box gluer?

2. How to clean and maintain the belt of the gluer?

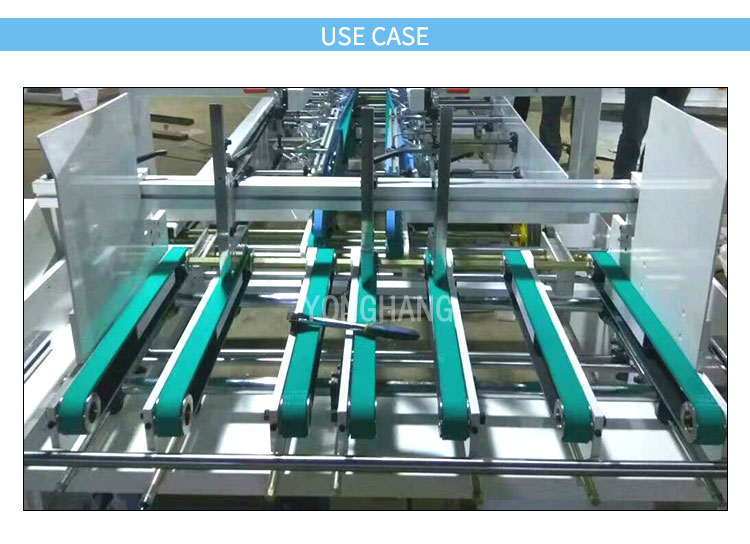

1. What are the main factors affecting the paste box belts?

(1) The gap between the main knife and the paste box belts of the gluing machine

The height of the installation position of the main control mechanism of the gluer directly affects the wear and tear of the paste box belts. Generally the number of sheets of paper conveyed by the main control knife mechanism should not exceed two.

(2) The tension force of the paste box belts should be moderate

Too loose tension will cause slippage with the roller; too tight will cause the belt to be over extended and reduce the service life of the paste box belts.

(3) The direction of the paste box belts operation

When the machine is running, the direction of the belt of the box gluer is consistent with the direction of the slope, if it is not consistent, the belt will easily cause the interface to break.

(4) In addition, you need to pay attention to the machine before running to check that there are no sharp objects around the belt in contact with it, thus avoiding direct wear and tear on the paste box belts.

2. How to clean and maintain the paste box belts?

Due to the material of the paste box belts itself, any organic solvents (e.g. alcohol, petrol, thinner, acetone, etc.) should be avoided when cleaning the belt, and only water or a mild household detergent should be used to achieve the cleaning effect. When it is necessary to rinse the belt with plenty of water, the belt should be removed from the machine (remember to mark the direction in which the belt is running). If the belt is under tension, the tensile layer of the nylon sheet in the middle of the belt is extremely sensitive to humidity and swelling and deformation in contact with water will affect the belt. The belt should be dried as soon as possible, even after rinsing it with plenty of water when it is not under tension, and should be dried in a well-ventilated environment for 24 - 36 hours to allow the nylon sheet of the belt to return to its normal moisture condition before reinstalling it on the machine.

Please contact us direct for more information regarding your specific requirements.

Whatapp&wechat:+ 0086 13725100585

Email :sales@yhbelt.com

Contact Details