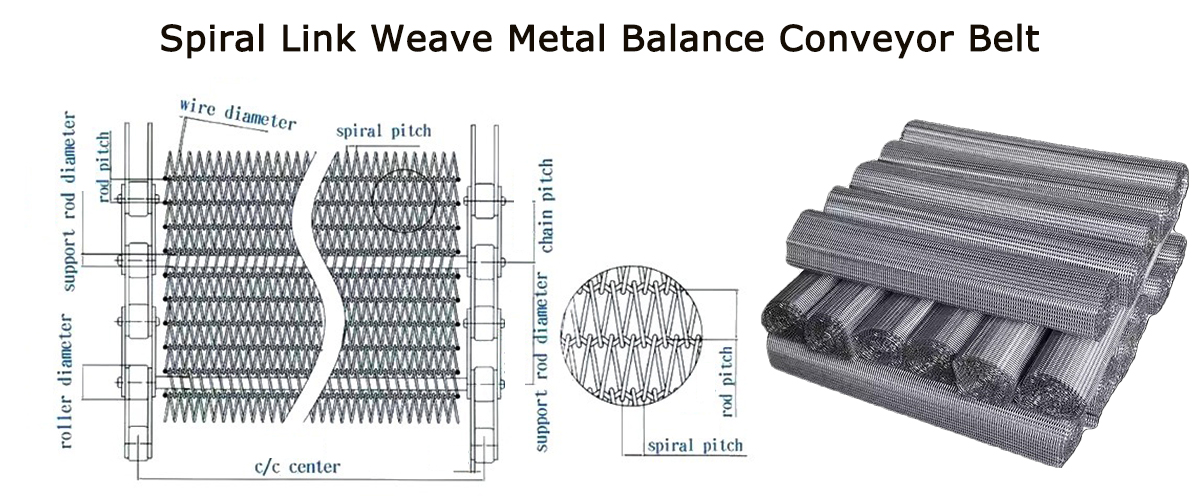

Spiral Link Weave Metal Balance Conveyor Belt

Spiral Link Weave Metal Balance Conveyor Belts, often called Balanced Mesh Belts, are a widely used type of conveyor belt known for their simple yet effective design. They are recognized for straight-running performance, excellent strength-to-weight ratio, and a wide range of mesh specifications to suit different applications

Specifications Table

Material selection: stainless steel 304, 314, 316, 316L, carbon steel, copper steel, brass steel and other types are available.

Surface treatment: galvanized, 3% chromium plate, manganese plated.

Spiral diameter: 0.9-3.0 mm.

Flat wire size (mm): from 1 × 0.7 to 6 × 3.

Cross rod pitch: 4-33 mm.

Belt speed: 0.5 m/min to 60 m/min.

Cross wire diameter: 1.2-4.0 mm.

Spiral wire pitch: 4-22 mm.

Belt width: up to 5 meters or more upon your request.

Edge type: welded edge, hook edge, laddered edge, chain link edge.

Basic Structure and Key Characteristics

The belt's structure consists of left-hand and right-hand spiral coils woven together and connected by crimped rods that run the width of the belt. This alternating spiral pattern provides several key characteristics:

Excellent Tracking: The alternating pattern prevents the belt from pulling to one side, promoting straight-line travel.

Strength and Flexibility: The interwoven spiral design offers a high strength-to-weight ratio and flexibility for various conveyor paths.

Multiple Drive Options: These belts are most commonly supplied as friction-driven. However, some meshes can be positively driven by sprockets that engage with the belt's mesh. For high-load applications, versions with chain edges are also available

These belts are versatile and found in many industries, including food processing, industrial manufacturing, glass and electronics production, and heat treatment processes

Common Applications

Food drying, washing, cleaning of mechanical parts

can handle heavier loads Heat treatment, annealing of parts, processing of leather and asbestos products

Improve tracking Electronics industry, glass industry, general manufacturing

Stability Cooling, drainage, heat treatment, annealing furnaces

Key Parameters and Selection Tips

When specifying a balanced weave conveyor belt, you will typically encounter a series of codes and numbers that describe its key parameters:

Example Model: B2.8/2.5-60-52W

B: Type prefix (Balanced)

2.8: Diameter (mm) of the spiral wire

2.5: Diameter (mm) of the connecting rod

60: Number of spiral coils per meter in the belt's width direction

52: Number of spiral coils per meter in the belt's length direction

W: Edge type (Welded)

For optimal performance, consider these factors during selection and use:

Material Selection: Belts are made from various materials, including carbon steel and different grades of stainless steel, to suit environments with moisture, heat, or corrosive chemicals.

Positive Drive for Heavy Belts: For tightly woven, heavy belts that require a lot of driving force, a positive drive system is more effective than friction drive. This system uses a drive roll with cavities that engage with protruding tangs on the belt for a non-slip grip.

Maintenance: Regularly adjust tensioning shafts to prevent the belt from running off track and maintain transmission components to ensure stable operation

I hope this overview helps you understand Spiral Link Weave Metal Balance Conveyor Belts. If you have a specific application, load requirement, or environmental condition in mind, I may be able to provide more targeted information.

Contact Details