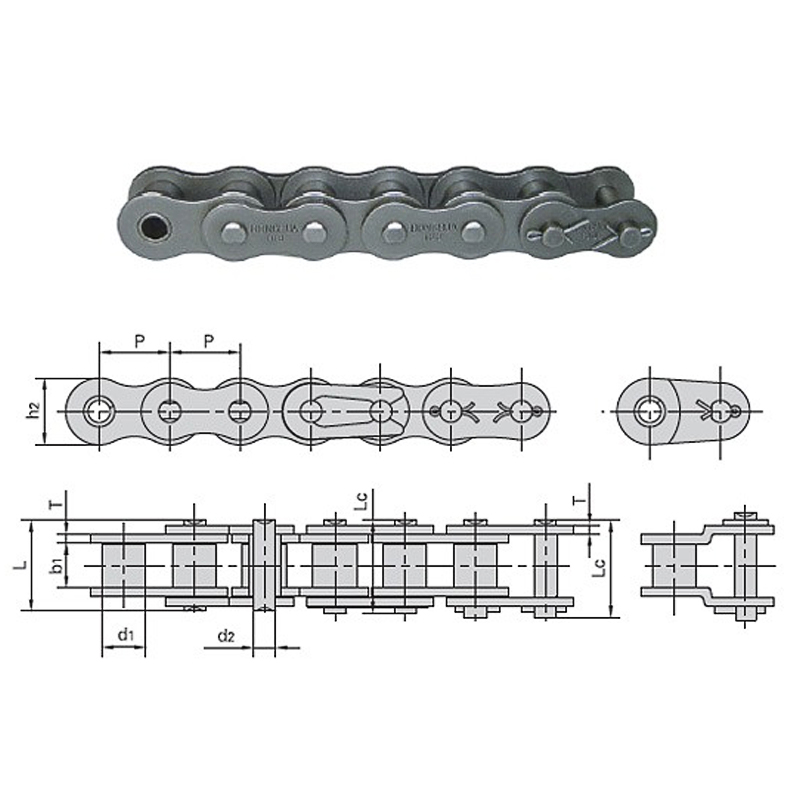

Single-strand roller chains

Single-strand Roller chain is a crucial component in many types of industrial equipment. At YONGHANG Roller Chain, we are proud to offer the best and strongest single-strand roller chains in the business. Compared to any respective quality at another company, single-strand roller chain is not found with the same maximum durability and lifetime as ours. Solid bushings on our roller chains are heat-treated, which increases their strength and longevity. Our roller chains also feature heat-treated and shot-peened side plates, allowing the chain to handle a greater work load. YONGHANG Roller Chain also offers additional connecting links and offset links for fixing your chain or customizing its length.

Single-strand roller chains

This Single-strand Roller chain Sizes is manufactured dimensionally to ANSI B29.1 and ISO standards, so it directly interchanges with other ANSI, DIN, and ISO certified chains. Though dimensionally equivalent this chain exceeds in strength, performance, and durability. Additionally, this Industrial roller chain is manufactured using heat-treated precision components and is supplied with a high-quality lubricant applied to the chain. For additional information or if you need assistance, please contact us, and we will be happy to assist you.

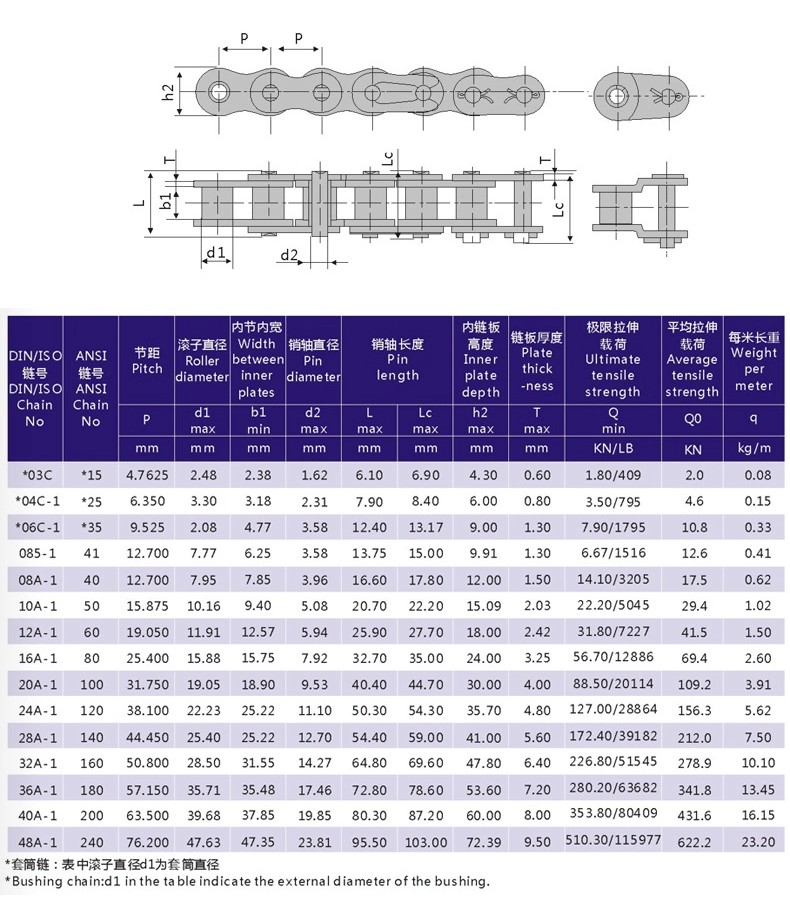

To help you find your suitable chain size more quickly, we have compiled the data sheet of Single-strand Roller chain Sizes for type A and type B. If you are interested, please contact us

Single-strand Roller chain Sizes

| Chain Number No. | Pith | Roller Diameter | Inner Width | Pin Diamete | Overall Width | Pin Width | Plate Thickness | ultimate tensile load | Average tensile load | Weght/meter | |

| P | d1 | b1 | d2 | L | Lc | h2 | T | ||||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/bf | kN | kg | |

| 04B-1 | 6.000 | 4.00 | 2.80 | 1.85 | 6.80 | 7.8 | 5.00 | 0.60 | 3.0/682 | 3.2 | 0.11 |

| 05B-1 | 8.000 | 5.00 | 3.00 | 2.31 | 8.20 | 8.9 | 7.10 | 0.80 | 5.0/1136 | 5.9 | 0.20 |

| 06B-1 | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.1 | 8.20 | 1.30 | 9.0/2045 | 10.4 | 0.41 |

| 08B-1 | 12.700 | 8.51 | 7.75 | 4.45 | 16.70 | 18.2 | 11.80 | 1.60 | 18.04091 | 19.4 | 0.69 |

| 10B-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.50 | 20.9 | 14.70 | 1.70 | 22.4/5091 | 27.5 | 0.93 |

| 12B-1 | 19.050 | 12.07 | 11.68 | 5.72 | 22.50 | 24.2 | 16.00 | 1.85 | 29.0/6591 | 32.2 | 1.15 |

| 16B-1 | 25.400 | 15.88 | 17.02 | 8.28 | 36.10 | 37.4 | 21.00 | 4.15/3.1 | 60.0/13636 | 72.8 | 2.71 |

| 20B-1 | 31.750 | 19.05 | 19.56 | 10.19 | 41.30 | 45.0 | 26.40 | 4.50/3.5 | 95.0/21591 | 106.7 | 3.70 |

| 24B-1 | 38.100 | 25.40 | 25.40 | 14.63 | 53.40 | 57.8 | 33.20 | 6/4.8 | 160.0/36364 | 178.0 | 7.10 |

| 28B-1 | 44.450 | 27.94 | 30.99 | 15.90 | 65.10 | 69.5 | 36.70 | 7.5/6.0 | 200.0/45455 | 222.0 | 8.50 |

| 32B-1 | 50.800 | 29.21 | 30.99 | 17.81 | 66.00 | 71.0 | 42.00 | 7.0/6.0 | 250.0/56818 | 277.5 | 10.25 |

| 40B-1 | 63.500 | 39.37 | 38.10 | 22.89 | 82.20 | 89.2 | 52.96 | 8.5/8.0 | 355.0/80682 | 394.0 | 16.35 |

| 48B-1 | 76.200 | 48.26 | 45.72 | 29.24 | 99.10 | 107.0 | 63.80 | 12.00/10.0 | 560.0A27272 | 621.6 | 25.00 |

| 568-1 | 88.900 | 53.98 | 53.34 | 34.32 | 114.6 | 123.0 | 77.80 | 13.50/12.0 | 850.0/193180 | 940.0 | 35.78 |

| 64B-1 | 101.600 | 63.50 | 60.96 | 39.40 | 130.0 | 138.5 | 90.17 | 15.00/13.0 | 112.0/254544 | 1240.0 | 46.00 |

| 72B-1 | 114.300 | 72.39 | 68.58 | 44.48 | 147.4 | 156.4 | 103.60 | 17.00/15.0 | 1400.0/318180 | 1550.0 | 60.80 |

Choose our advantages—we meticulously craft every detail

Retaining rings

Pins

Rigorous material selection ensures extended service life

Superior craftsmanship delivers exceptional toughness

Durable and long-lasting

Carburized and quenched for enhanced hardness

Premium steel selection

Smooth chain passage through bends

Years of precision polishing

Effortless movement without jamming

Smooth surface free of burrs

Hardened chain plates

Crack-resistant plates with guaranteed tensile strength

Enhanced hardness and strength for extended chain lifespan

ONE.1

Premium Steel

High-density steel breaking, continuously tempered

Exceptional toughness

Resistant to breakage, extended service life

TWO.2

High-Frequency Quenching

Strictly controlled heat treatment to exacting standards

Enhanced hardness/strength

Deep quenching ensures crack resistance and superior wear resistance

THREE.3

Smooth Surface

Smooth product surface, burr-free, meticulously finished

High strength, high torque capacity, worry-free operation

Contact Details