Rubber Block Chain

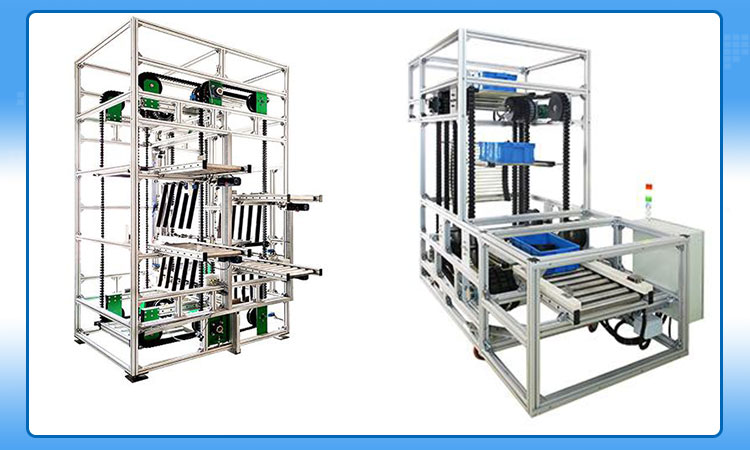

yonghang original rubber block chain is an important component in Continuous Vertical Conveyor, Reciprocating Lifts or bucket transport systems for bulk material.

At the heart of all our conveying systems lies the heavy-duty NERAK rubber block chain.

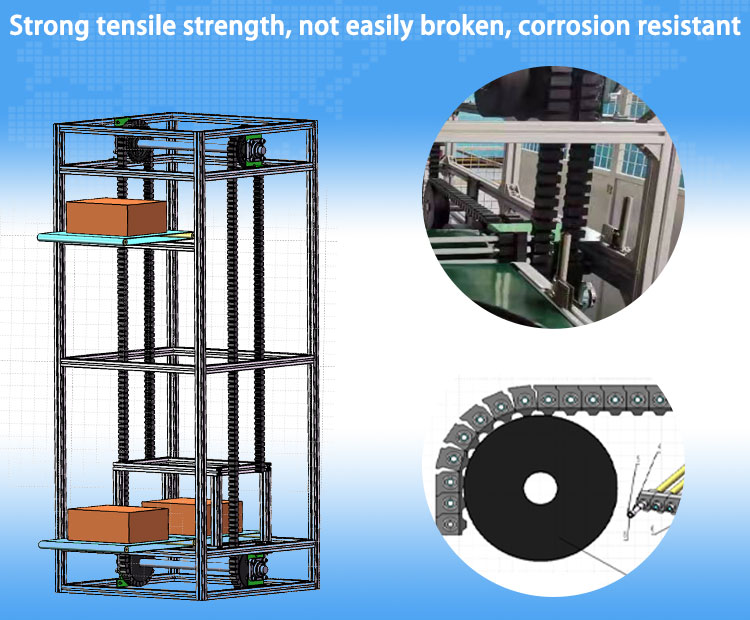

The rubber outer layer is tightly bonded to high-strength flexible steel cables through a high-pressure vulcanization process.

Even under the most demanding operating conditions—such as when used on rubber extrusion cooling lines where the conveyor belt remains continuously submerged in water—the robust bond between the rubber skeleton and inner steel cables ensures completely corrosion-free operation and an exceptionally long service life. All NERAK rubber block chains are manufactured in our own modern factory, enabling us to guarantee the correct type and style of rubber chain for every application.

Rubber Block Chain Features include:

Maintenance-free

No corrosion

Silent operation

Wear-resistant

Without hinges

Yonghang original rubber block chain is an important component in Continuous Vertical Conveyor, Reciprocating Lifts or bucket transport systems for bulk material.

Yonghang rubber block chain operates grease free, and therewith clean compared to steel chains.

Rubber block chain made of modified natural rubber operate very quiet and avoid the necessarity to wear ear protection when working nearby.

Rubber block chain are very strong, with steel cables inside and a reliable binding between rubber and steel cables.

Rubber block chain come with a lock for easy installation, or endless vulcanized for better resistance against weather and aggressive pollution influence.

Yonghang uses rubber block chain in own machines for reliable and quiet operation, and also offers the chains as spare parts and replacement in other machines operating with a similar system.

Features include:

Maintenance-free

No corrosion

Silent operation

Wear-resistant

Without hinges

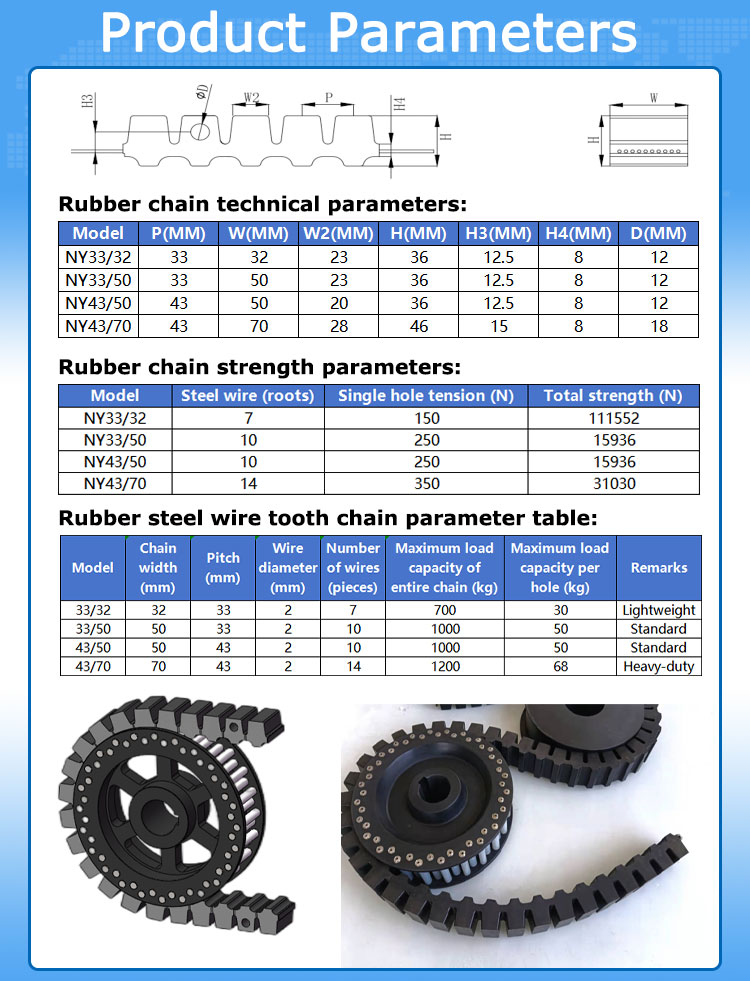

As the core component of vertical lifting equipment, Yonghang rubber block chain is manufactured with several specially processed high-tension wire ropes that are used as the rubber chain skeleton and rubber through high temperature and high pressure fluidizing process. Application scenario: Yonghang Rubber Chains have achieved reliable high-quality application in continuous elevator, grab elevator, reciprocating elevator, straight cross sorting machine, recirculating fork vertical elevator, etc. Model (as shown below): Multiple specifications and lengths can be customized based on customer requirements, which can be annular or linked by hinges.

Not applicable scenario: It is not suitable for the toothless drive wheel of continuous bucket elevator, but the drive wheel with synchronous teeth shall be adopted.

Working environment: Indoor light-proof,-15 C 40 C. dry without corrosion.

Special point: Lubrication-free O Keep running quietly without noise (below 60 dB) Non-elongation O Because there is a wire rope skeleton structure inside the rubber chains and there is almost no tension, they keep the chain length unchanged throughout the service life.

Lubrication-free O Lubrication is not required. Since it is lubrication-free and the surface is smooth and clean, it can be cleaned with air or water It is very suitable for dust environment and food field.

Maintenance-free During operation, the chain is free of lubricant and frequent tension adjustment. Wear resistance transportation. No powder pollution of the environment will occur during

Application

Vertical circulation conveyor

Z-type wrapper elevator

Vertical conveyor (multi-inlet and outlet)

C-type wrapper elevator

Yonghang C-type wrapper elevator

WB-type elevator

WS-type grab elevator

Type C Continuous Vertical Elevator

Reciprocating Vertical Elevator

Bucket Vertical Elevator

Multi-in Multi-out Vertical Elevator

Product image

All yonghan rubber block chains are manufactured in its own modern factory, enabling the company to ensure it can supply the correct type and style of rubber chain for each application.

Contact Details