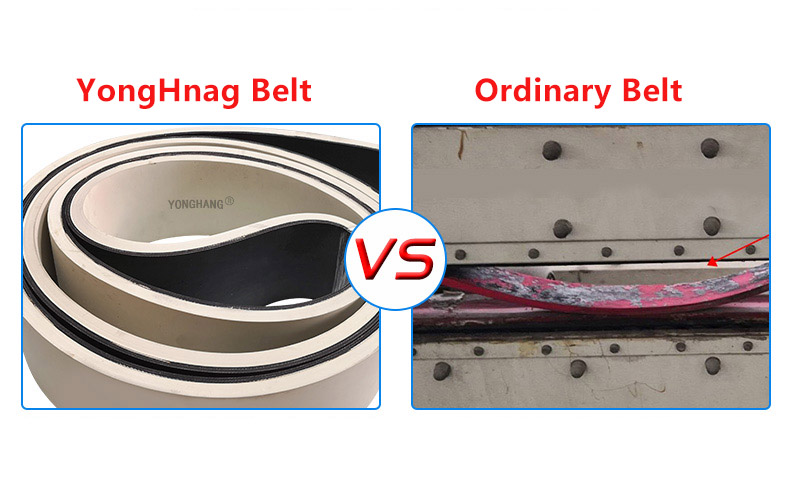

Yonghang fiber optical cable belts because of its high quality, long service life and hight quality by the customer's favorite! Today will introduce you about the structure composition of its fiber optical cable belts!

12 Years Transmission Belts Coating Customized Factory.

The Three Structural Components Of YongHang Fiber Optical Cable Belts!

2022-06-01

×

Yonghang fiber optical cable belts consists of a neoprene backing, a tensile layer (nylon core) and a nylon anti-slip fabric layer.

(1) Neoprene backing.

Neoprene backing consists of a 4mm thick bottom layer plus 8mm rubber, which firmly bonds the nylon core to the rubber layer, playing an anti-pull role, preventing damage caused by friction, which with the advantages of superior hydrolysis, heat resistance and aging resistance! The thickened rubber on the back of the belt gives the belt more protection against corrosion to improve the load carrying capacity!

(2) Tensile layer (nylon core).

The tensile layer is a high-strength nylon thread core layer, formed by multiple strands of nylon thread rope spiral along the width of the tape, with good flex resistance and low elongation, strong tensile strength, so that the belt has good dimensional stability!

(3) Nylon anti-slip fabric layer.

Nylon anti-slip fabric layer consists of nylon fabric with small coefficient of friction, which is the anti-wear part of the protection belt and has superior dense resistance, improves the performance of the belt in operation, reduces noise and friction coefficient, anti-slip and wear resistance, reduces kinetic energy consumption, improves transmission efficiency, and greatly enhances the service life of the belt!

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :sales@yhbelt.com

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

Recommended for you

no data

Get in touch with us

Useful Links

Contact Details

Add:

4th Floor, Building B8, Chuangbao Creative Park, Federal Industrial Zone, West Yushan Road, Panyu District, Guangzhou, China. 511400

Tel: +86 134 1810 3085

E-mail: sales@yhbelt.com

Copyright © 2026 Guangzhou Yonghang Transmission Belt Co., Ltd. - www.yhbelt.com All Rights Reserved. | Sitemap | Privacy Policy

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service