Haul-offs are pulley-driven parallel belts that contact opposite sides of in-process products, usually by means of rollers exerting suitable pressure for the belts to grip and haul them, with the desired controlled pulling action.

Red rubber Cable Traction Extrusion haul off belts for PE foam pipe & tube

YONGHANG supplies Haul-off belts for all types of extruders, including caterpillar haul-off for cables, wires, pipes and profiles.

Haul-offs” are pulley-driven parallel belts that contact opposite sides of in-process products, usually by means of rollers exerting suitable pressure for the belts to grip and haul them, with the desired controlled pulling action.

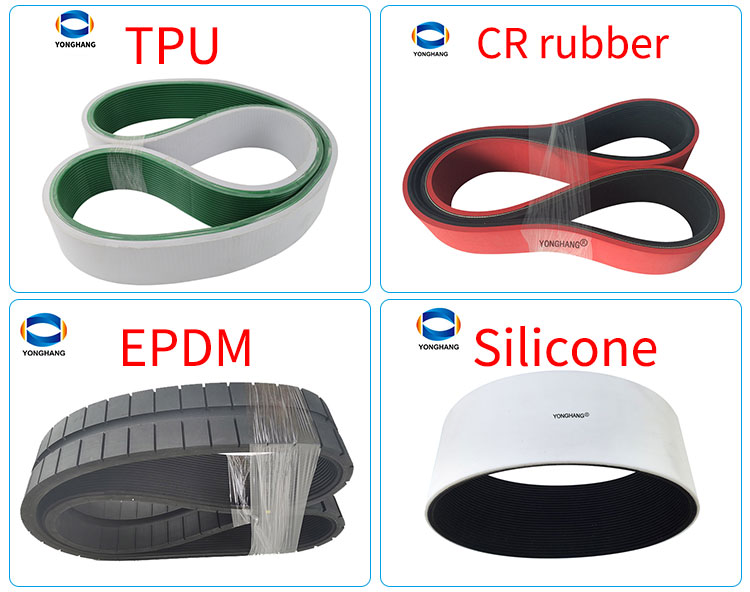

Our range includes specific combination of base belts, tensile strengths and fabrication details to meet technical requirements of variety of extrusion applications, including specific resistance, hardness, temperature, friction needs.

Why is Yonghang's Haul-off belts considered the most reliable belt?

1. Yonghang Haul-off belts are molded in one piece through vulcanization, ensuring true seamless construction that prevents delamination and breakage.

2. Tested to withstand 1,000 friction cycles with only 0.1% wear, Yonghang Haul-off belts utilize the most durable modified CR rubber.

3. Compared to splicing rubber belts requiring three replacements annually, Yonghang Haul-off belts need only one replacement per year, significantly reducing costs.

4. Custom EPDM high-temperature resistant rubber Haul-off belts and TPU materials available.

What are the differences between EPDM high-temperature resistant rubber Haul-off belts and TPU materials?

| Property | EPDM Rubber | TPU |

| Material Type | Thermoset Rubber (requires vulcanization) | Thermoplastic Elastic(can be melted and reshaped) |

| High-Temperature | -50℃ to 150℃ | -40℃ to 120℃ |

| Low-Temperature Flexibility | Excellent; remains flexible at very low temperatures | Not tolerant of low temperatures |

| Abrasion & Wear Resistance | Good | Excellent; outstanding abrasion resistance |

| Mechanical Strength (Tensile, Tear) | Good | Excellent; high mechanical strength |

| Oil & Fuel Resistance | Poor; not recommended for oil exposure | Excellent;maintains performance in oily environments |

| Weather/Ozone Resistance | Outstanding;excellent resistance to sunlight, ozone, and weathering | inferior to EPDM |

| Chemical Resistance | Good resistance to polar solvents, acids, and alkalis; | Good resistance to oils and fuels; may be attacked by strong acids, bases, and polar solvents |

| Processing Method | Vulcanization (time-consuming, | Injection Molding, Extrusion (fast, recyclable) |

How to Choose the Right Material

Your choice between EPDM and TPU should be based on the specific operating conditions and requirements of the traction belt:

Choose EPDM if your primary concerns are long-term resistance to high heat (above 120℃), ozone, and weathering. EPDM is the classic choice for applications like industrial conveyor belts or outdoor machinery where extreme heat stability and environmental aging are critical

Choose TPU if the traction belt requires superior abrasion resistance, high mechanical strength, and good resistance to oils and fuels. TPU is ideal for applications with high wear and tear or where contact with lubricants is expected. Its thermoplastic nature also offers advantages in manufacturing efficiency and recyclability

Why choose Yonghang's CR rubber traction belt?

The greatest advantage of our modified CR is its low price, which is suitable for ordinary traction machines. The operating temperature range is between -20- 80℃. It has general durability and the Yonghang traction machine belts that Seamless integral vulcanizationr with molds can be used for more than one year.

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :sales@yhbelt.com

Contact Details