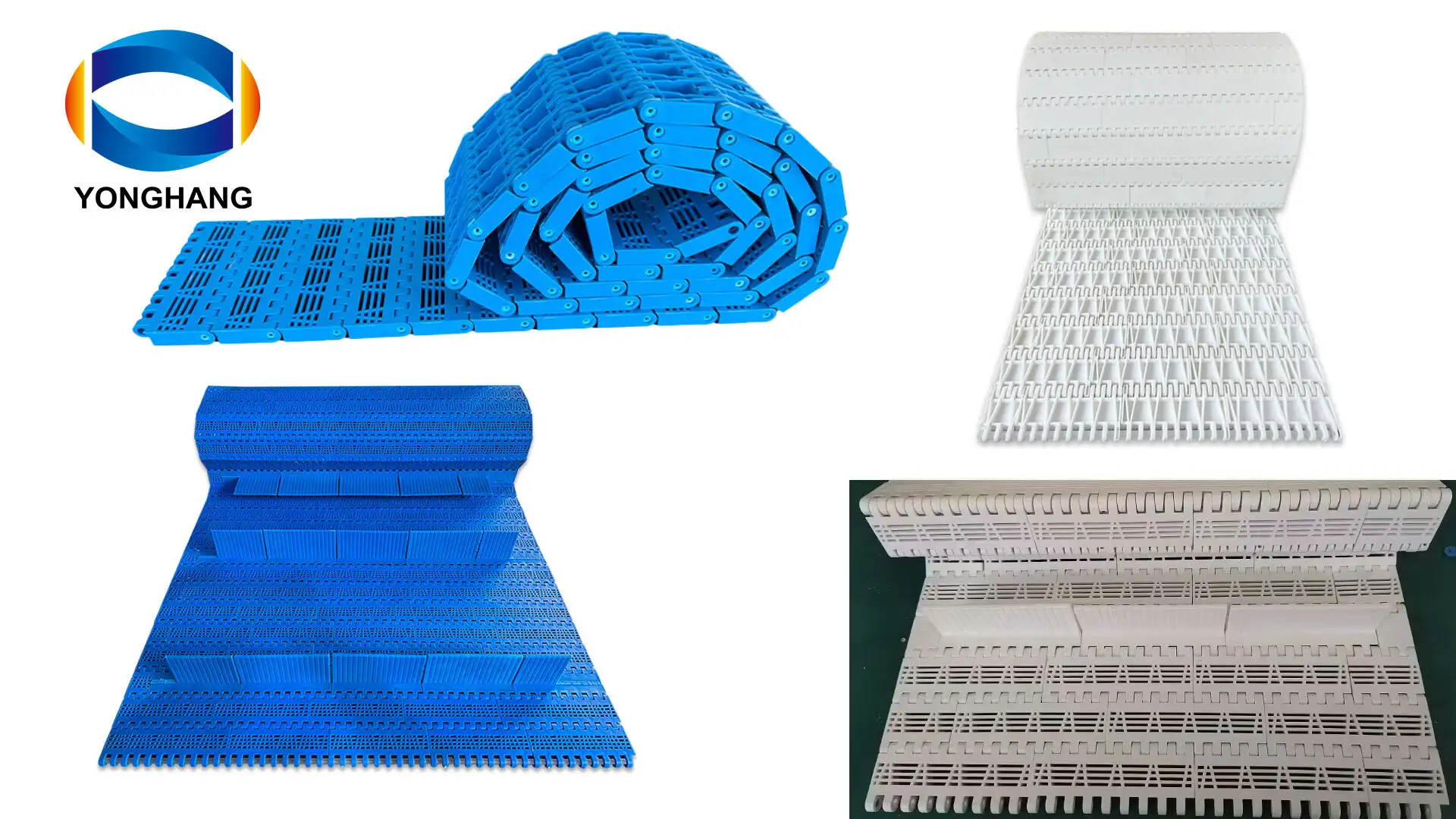

OPB series plastic modular conveyor belt Pitch 50.8mm

OPB series plastic modular conveyor belt type include :Pitch,Pin Diameter,Working load(max),Weight,thickness,Back flex radius,Work Temperature,Standard Width(Single piece),Non-standard Width (Assembly),Open Area, Description, advantages, and applications, etc.

Pitch(mm): 50.8mm/2 inch

Belt Material : POM/PP

Pin Material: POM/PP/PA6

OPB Series modular plastic conveyor Belts are categorized as follows:

OPB modular plastic flat top conveyor belt

OPB with hole flat top plastic conveyor belt

OPB modular plastic flush grid conveyor belt

OPB with big hole plastic conveyor belt

and OPB Series Accessories

The materials we can produce include POM, PP, PE, and steel-like materials can be used for POM/PP/PA6.The color of the belt can be brown, white, or blue. The most common ones are: PP (polypropylene) is white, and POM (polyoxymethylene) is blue and brown.We can also customize the color according to your requirements.

You can choose the style that suits you best to place your order. If you don't find what you're looking for, please contact us—we'd be happy to assist you.

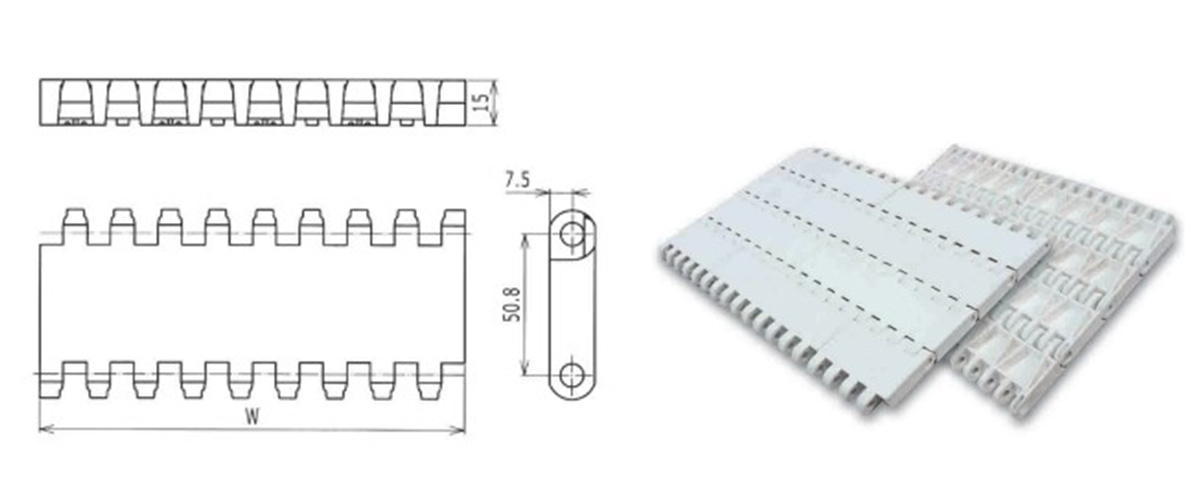

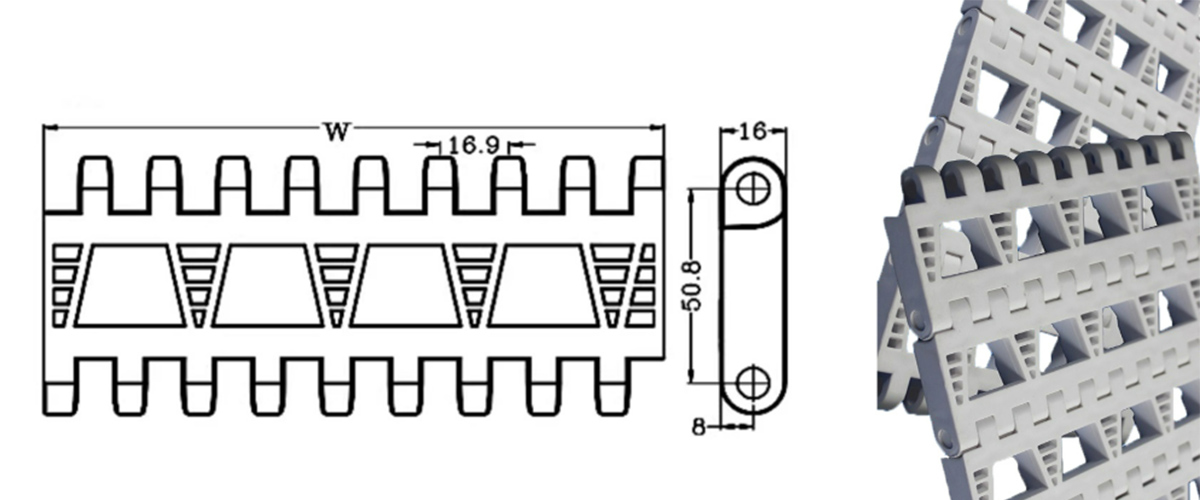

OPB modular plastic flat top conveyor belt

| OPB modular plastic flat top conveyor belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius(min) | Work Temperature | Standard Width(Single piece) | Non-standard Width (Assembly) |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| OPB | 50.8 | POM | PP | 8 | 22000 | 12 | 15 | 75 | -30℃~+80℃ | 152.4*N | 152.4+16.9*N N is an even number |

| 50.8 | PA | 8 | 25000 | 12.1 | 15 | 75 | -30℃~+90℃ | 152.4*N | |||

| 50.8 | PP | PP | 8 | 11000 | 7.8 | 15 | 75 | +4℃~+104℃ | 152.4*N | ||

| 50.8 | PE | PE | 8 | 6600 | 8.2 | 15 | 75 | -40℃~+65℃ | 152.4*N | ||

| Open Area 0% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

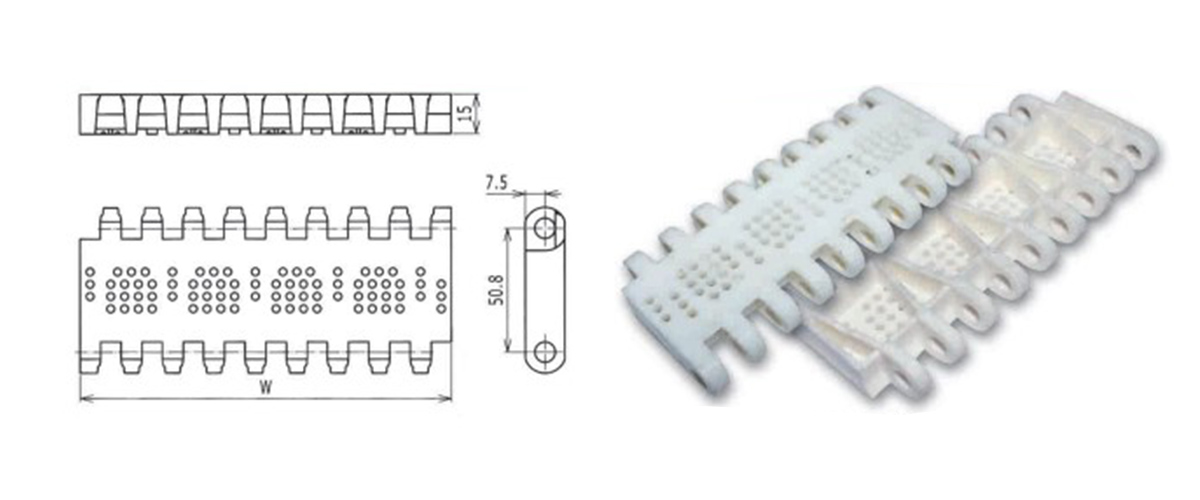

OPB with hole flat top plastic conveyor belt

| OPB with hole flat top plastic conveyor belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius(min) | Work Temperature | Standard Width(Single piece) | Non-standard Width (Assembly) |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| OPB | 50.8 | POM | PP | 8 | 22000 | 11.7 | 15 | 75 | -30℃~+80℃ | 152.4*N | 152.4+16.9*N N is an even number |

| 50.8 | PA | 8 | 25000 | 12 | 15 | 75 | -30℃~+90℃ | 152.4*N | |||

| 50.8 | PP | PP | 8 | 11000 | 7.5 | 15 | 75 | +4℃~+104℃ | 152.4*N | ||

| 50.8 | PE | PE | 8 | 6600 | 7.3 | 15 | 75 | -40℃~+65℃ | 152.4*N | ||

| Open Area 12% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

OPB modular plastic flush grid conveyor belt

| OPB modular plastic flush grid conveyor belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius(min) | Work Temperature | Standard Width(Single piece) | Non-standard Width (Assembly) |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| OPB | 50.8 | POM | PP | 8 | 22000 | 10.1 | 15 | 75 | -30℃~+80℃ | 152.4*N | 152.4+16.9*N N is an even number |

| 50.8 | PA | 8 | 25000 | 10.2 | 15 | 75 | -30℃~+90℃ | 152.4*N | |||

| 50.8 | PP | PP | 8 | 11000 | 6.9 | 15 | 75 | +4℃~+104℃ | 152.4*N | ||

| 50.8 | PE | PE | 8 | 6600 | 8.2 | 15 | 75 | -40℃~+65℃ | 152.4*N | ||

| Open Area 23% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

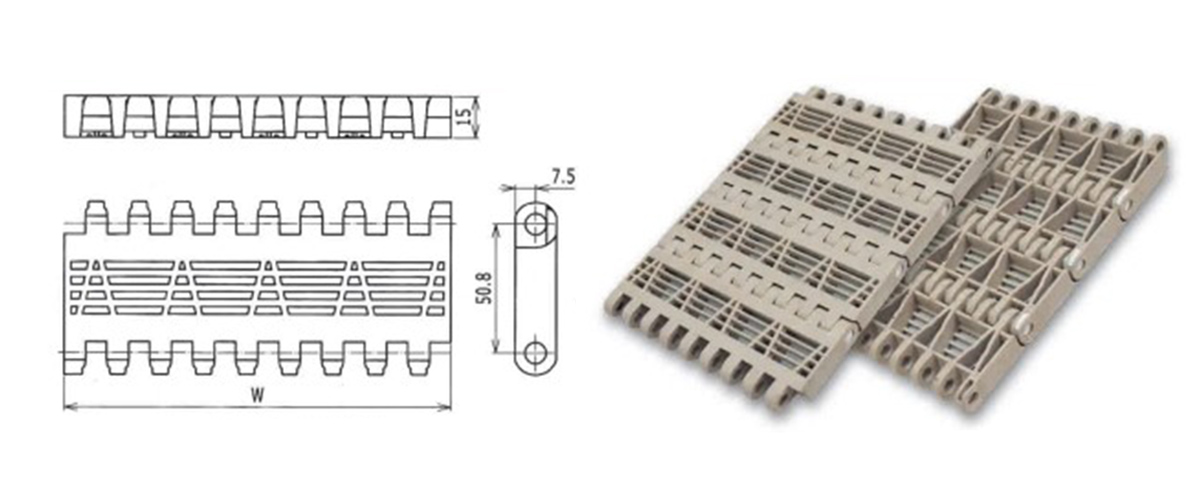

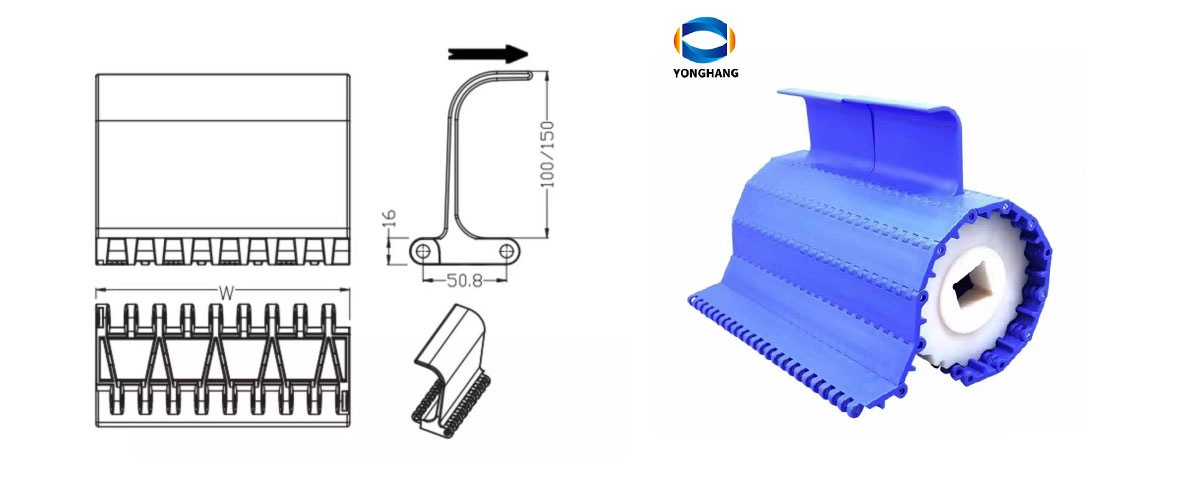

OPB with big hole plastic conveyor belt

| OPB with big hole plastic conveyor belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius (min) | Work Temperature | Standard Width(Single piece) | Non-standard Width (Assembly) |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| OPB | 50.8 | POM | PP | 8 | 22000 | 9 | 16 | 75 | -30℃~+80℃ | 152.4*N | 152.4+16.9*N N is an even number |

| 50.8 | PA | 8 | 23000 | 9.1 | 16 | 75 | -30℃~+90℃ | 152.4*N | |||

| 50.8 | PP | PP | 8 | 11000 | 6.8 | 16 | 75 | +4℃~+104℃ | 152.4*N | ||

| 50.8 | PE | PE | 8 | 6600 | 7.2 | 16 | 75 | -40℃~+65℃ | 152.4*N | ||

| Open Area 36% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

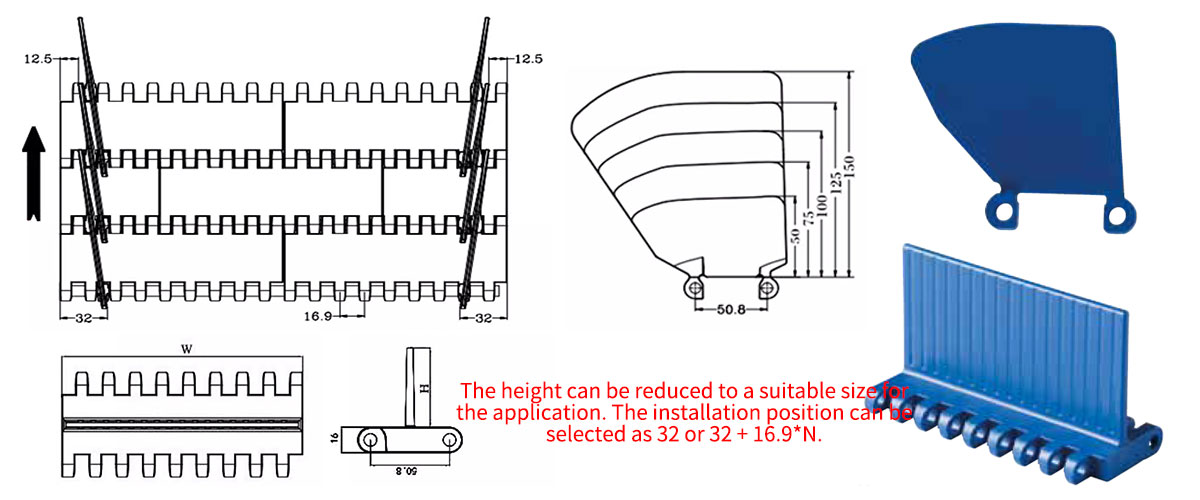

OPB Series Accessories

H:30/50/75/100/125/150

It is essential to note that these accessories(flight and Side Guard) are compatible with all models in the OPB series. They can be manufactured in all materials used for the OPB series and can also be custom-molded to order.

Curve flight

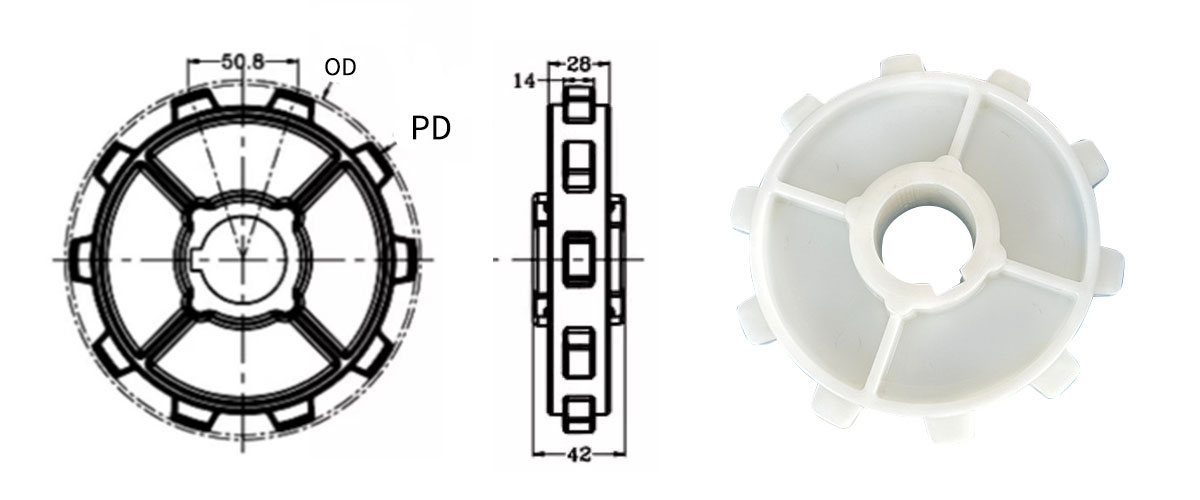

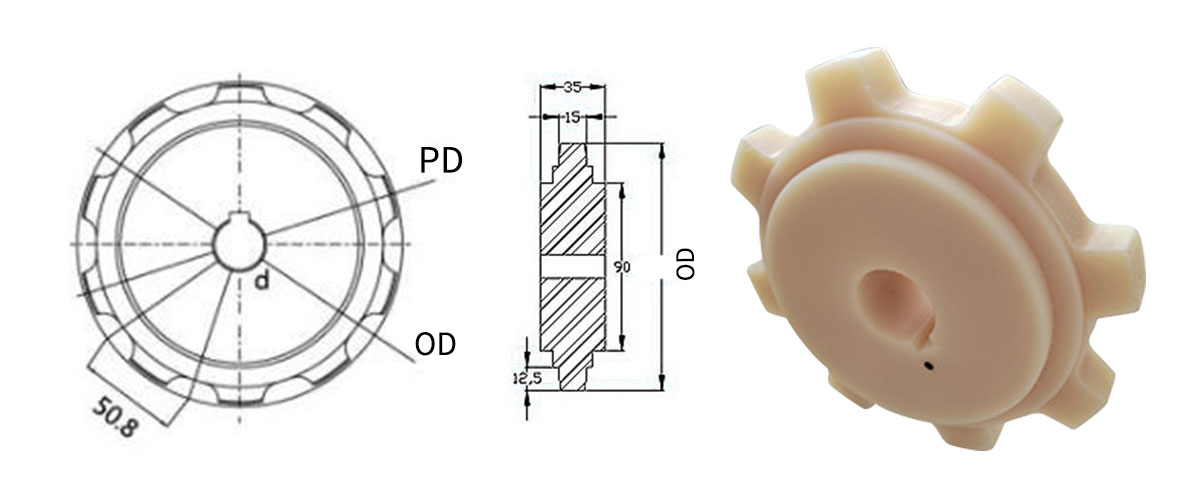

Injection molded sprocket

Machined Sprockets

| Sprockets | Pitch | Teeth | Pitch Diametet PD | Outside Diameter | Bore Size (Round hole and D hole) | forming way | ||

| mm | mm | Inch | mm | Inch | mm | |||

| OPB Sprockets | 50.8 | 6 | 101.6 | 4 | 101.6 | 4.00 | 20-35 | machined |

| OPB Sprockets | 50.8 | 7 | 117.1 | 4.61 | 117.1 | 4.61 | 20-35 | machined |

| OPB Sprockets | 50.8 | 8 | 129 | 5.08 | 132.8 | 5.23 | 30-50 | injection and machined |

| OPB Sprockets | 50.8 | 9 | 148.5 | 5.85 | 148.9 | 5.86 | 30-50 | machined |

| OPB Sprockets | 50.8 | 10 | 160.5 | 6.32 | 164.4 | 6.47 | 30-50 | injection and machined |

| OPB Sprockets | 50.8 | 12 | 193 | 7.60 | 196.3 | 7.73 | 40-60 | machined |

| OPB Sprockets | 50.8 | 13 | 207.3 | 8.16 | 208.9 | 8.22 | 40-70 | machined |

| OPB Sprockets | 50.8 | 14 | 225.5 | 8.88 | 228.3 | 8.99 | 40-70 | machined |

| OPB Sprockets | 50.8 | 16 | 255 | 10.04 | 256.3 | 10.09 | 40-70 | machined |

| Special tooth counts can be customized. The shaft diameter can be square or round. The injection molded Sprockets material can be POM, PP, or PA. The machined material can be PA/PP. | ||||||||

Description:

The OPB Plastic module conveyor belt with different materials can play a different role in conveying to meet the needs of different environments, through the modification of plastic materials so that the conveyor belt can meet the requirements of environmental temperature between -30° and 104° Celsius.

Conveyor belt material has PP, PE, POM, PA,Anti-static materials, etc.

The structure forms can be: horizontal straight line conveying, lifting and climbing conveying and other forms, conveyor belt can be added with lifting baffle, side baffle.

Modular conveyor belt with plastic hinged pin extending on the whole width of the conveyor belt, the injection molded conveyor belt assembly into interlocking unit, this method increases the strength of the conveyor belt, and can be connected into any required width and length. Baffle and side plate can also be interlocked with hinged pins, becoming one of the integral parts of the plastic steel conveyor belt.

OPB with big hole plastic conveyor belt applicable for high hollow requirements and good drainage effect conveyor.

It is the first recommended conveyor belt for cleaning industry.

Range of application:

suitable for drying,

dewetting,

freezing, Pig, sheep, chicken, duck, slaughter cutting processing

fruit sorting cleaning,

Packaging line

Aquatic processing production line

Quick-frozen food production line

Battery production

Beverage production

Can Conveying

Agricultural processing industry

Chemical industry

Electronic industry

Rubber and plastic manufacturing industry

Cosmetics industry

General conveying operation

Advantage

1. Can be easily repaired

2. Easily clean

3. Variable speeds can be fitted

4. The baffle and side wall can be easily fitted.

5. Many kinds of food products can be transported

6. Dry or wet products are ideal on modular belt conveyors

7. Cold or hot products can be transported.

Contact Details