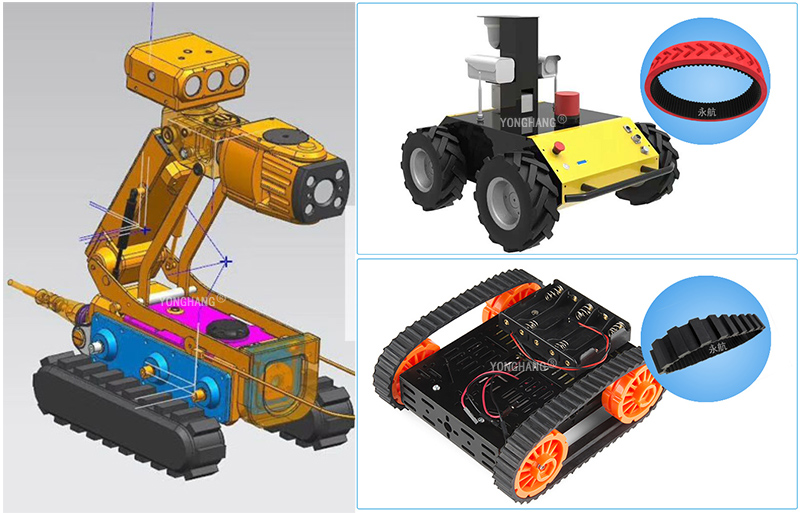

YongHang robot track belt adopts the seamless molding process of mold integrated vulcanization, adopts the ring-shaped tape made of three main materials: neoprene, glass fiber cord and nylon elastic cloth, and adopts synchronous belt meshing type transmission, which has the characteristics of low ground pressure, high traction, low vibration for climbing stairs, low noise, good passability in wet fields, not easy to damage the road, and fast driving speed, etc.! robot track belt is mainly used in industrial robots, special operation robots, service robots, micro robots and other intelligent crawler robots for walking, overcoming obstacles, climbing stairs and other actions!

Common customizable types of YongHang robot track belt:

1.Surface grooving - thickened red rubber surface, open regular grooving, increase friction and grip force!

2. Surface thickening grooving - belt thickening one vulcanization, grooving and grinding on the surface to form a square block, play the role of anti-skid!

3. Bottom belt grinding teeth - special grinding grooves on the surface to enhance the grip, bottom belt grinding teeth on both sides to keep flat!

How to customize robot track belt?

1. we must determine the circumference. This is calculated by multiplying the center distance between the wheels by 2, then adding the radius of both wheels.

2.determine the track width.

3.determine the thickness (typically selected based on the wheel diameter).

4.determine the track shape. Common choices include synchronous belts, multi-v-belts, and flat belts as the base, with specialized rubber tread patterns applied to the surface to achieve the required friction coefficient.

Below are some of the cases we have handled. If you also need custom robot tracks, please contact us.![How to customize robot track belt? 1]()

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+0086 13725100582

Email : sales@yhbelt.com