Standard dimensions for sprockets

The standard dimensional parameters of sprockets primarily include the number of teeth, pitch diameter, top diameter, root diameter, and tooth width. Below is a detailed introduction to the standard dimensional parameters of sprockets.

Our company offers a comprehensive range of sprocket chains, gears, and racks, with over 8,000 specifications currently available. We maintain substantial inventory for immediate shipment, and can also customize products based on customer drawings and specifications. Contact our customer service team for a quote!

Our sprocket gear series is manufactured in-house. We currently operate three CNC gear hobbing machines, six CNC lathes, eight CNC and manual milling machines, six horizontal broaching machines and wire cutting machines, along with twelve other auxiliary devices. We offer custom manufacturing based on customer drawings, featuring short lead times, consistent quality, high precision and concentricity, and exceptional durability.

As a specialized manufacturer of factory automation components, our company boasts a professional R&D team and skilled production technicians. 90% of our product range can replace Misumi and industry-standard models to meet customer design and production needs. Due to the extensive variety of models, only a portion of our products are listed on various websites. We welcome inquiries from all customers.

Machinable Materials

Metals (copper, stainless steel, aluminum, 45 steel),

Non-metals (FR4, PE, PP, POM, and various plastics).

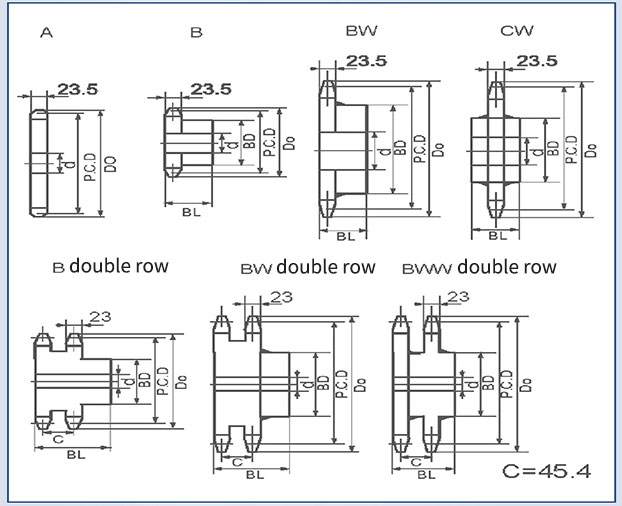

Basic Dimensional Parameters of Sprockets

1. Number of Teeth (Z): The number of teeth refers to the quantity of teeth on a sprocket and is one of its fundamental parameters.

2. Pitch Circle Diameter (D): The pitch circle diameter denotes the diameter of the circle on which the centers of the chain rollers lie. It is calculated as: D = p * (Z / 2π), where p is the chain pitch.

3. Tip Circle Diameter (Da): The tip circle diameter is the diameter of the circle where the tooth tips lie on the sprocket. It is calculated as: Da = D + 2 * h * a, where h is the tooth height and a is the tip height coefficient.

4. Root Circle Diameter (Df): The root circle diameter is the diameter of the circle on which the roots of the teeth on the sprocket lie. The formula is: Df = D - 2 * h * (1 - a), where h is the tooth height and a is the tooth height coefficient.

5. Tooth Slot Width (b): The tooth slot width refers to the gap width between two adjacent teeth on the sprocket. The calculation formula is: b = p / 2.

Standard Sizes Series for Sprockets

The standard sizes series for sprockets refers to the size series defined by international or national standards, primarily including the following types:

ISO Standard Sprocket Size Series:

The ISO standard sprocket size series primarily includes 40, 50, 60, 70, 80, 90, 100, 110, 120, 130, 140, 150, 160, 170, 180, 190, 200, 210, 220, 230, 240, 250, 260, 270, 280, 290, 300, 310, 320, 330, 340, 350, 360, 370, 380, 390, 400, 410, 420, 430, 440, 450, 460, 470, 480, 490, 500, 510, 520, 530, 540, 550, 560, 570, 580, 590, 600, 610, 620, 630, 640, 650, 660, 670, 680, 690, 700, 710, 720, 730, 740, 750, 760, 770, 780, 790, 800, 810, 820, 830, 840, 850, 860, 870, 880, 890, 900, 910, 920, 930, 940, 950, 960, 970, 980, 990, 1000.

DIN Standard Sprocket Size Series:

●The DIN standard sprocket size series primarily includes 40, 50, 60, 70, 80, 90, 100, 110, 120, 130, 140, 150, 160, 170, 180, 190, 200, 210, 220, 230, 240, 250, 260, 270, 280, 290, 300, 310, 320, 330, 340, 350, 360, 370, 380, 390, 400, 410, 420, 430, 440, 450, 460, 470, 480, 490, 500, 510, 520, 530, 540, 550, 560, 570, 580, 590, 600, 610, 620, 630, 640, 650, 660, 670, 680, 690, 700, 710, 720, 730, 740, 750, 760, 770, 780, 790, 800, 810, 820, 830, 840, 850, 860, 870, 880, 890, 900, 910, 920, 930, 940, 950, 960, 970, 980, 990, 1000.

ASME Standard Sprocket Size Series:

●The ASME standard sprocket size series primarily includes 40, 50, 60, 70, 80, 90, 100, 110, 120, 130, 140, 150, 160, 170, 180, 190, 200, 210, 220, 230, 240, 250, 260, 270, 280, 290, 300, 310, 320, 330, 340, 350, 360, 370, 380, 390, 400, 410, 420, 430, 440, 450, 460, 470, 480, 490, 500, 510, 520, 530, 540, 550, 560, 570, 580, 590, 600, 610, 620, 630, 640, 650, 660, 670, 680, 690, 700, 710, 720, 730, 740, 750, 760, 770, 780, 790, 800, 810, 820, 830, 840, 850, 860, 870, 880, 890, 900, 910, 920, 930, 940, 950, 960, 970, 980, 990, 1000.

III. Selection Principles for Sprocket Dimensions

1. Selection Based on Chain Pitch: Sprocket dimensions must match the chain pitch to ensure proper meshing between the chain and sprocket.

2. Selection Based on Sprocket Teeth Count: The number of sprocket teeth should be determined based on the transmission ratio and chain pitch to meet the requirements of the transmission system.

3. Selection Based on Sprocket Diameter: The sprocket diameter should be calculated based on the sprocket tooth count and chain pitch to ensure the sprocket pitch circle diameter matches the chain pitch.

4. Selection Based on Sprocket Top Circle Diameter: The sprocket top circle diameter should be calculated based on the sprocket tooth count and chain pitch to ensure the sprocket top circle diameter matches the chain pitch.

5. Select based on the sprocket's root circle diameter: The sprocket's root circle diameter should be calculated based on the number of teeth and the chain pitch to ensure the sprocket's root circle diameter matches the chain pitch.

6. Selection based on sprocket tooth width: The tooth width of the sprocket should be calculated based on the chain pitch to ensure the sprocket tooth width matches the chain pitch.

The standard dimensional parameters of sprockets are critical factors in ensuring proper meshing between sprockets and chains. When selecting sprocket dimensions, comprehensive consideration should be given to factors such as chain pitch, sprocket tooth count, sprocket diameter, sprocket pitch diameter, sprocket root diameter, and sprocket tooth width to guarantee the stability and reliability of the transmission system. This article provides a foundational overview of sprocket product knowledge compiled by Yonghang Transmission Wheel Parts. It aims to help users across industries deepen their understanding of the product, better select high-quality products that meet their enterprise needs, and resolve challenges encountered during product selection. For any additional questions, feel free to consult yonghang Automation at no cost.

Contact Details