PTFE Conveyor belt teflon high temperature Grid belt

Teflon belt, also known as Teflon mesh belt, PTFE conveyor belt, is an industrial conveyor belt made of glass fiber cloth coated with polytetrafluoroethylene (PTFE) resin. It is mainly used in textile printing and dyeing drying, food baking transmission, ultraviolet curing equipment, pharmaceutical sterilization production line and electronic and electrical manufacturing, etc. It is suitable for high temperature, corrosive environment of the material conveying needs.

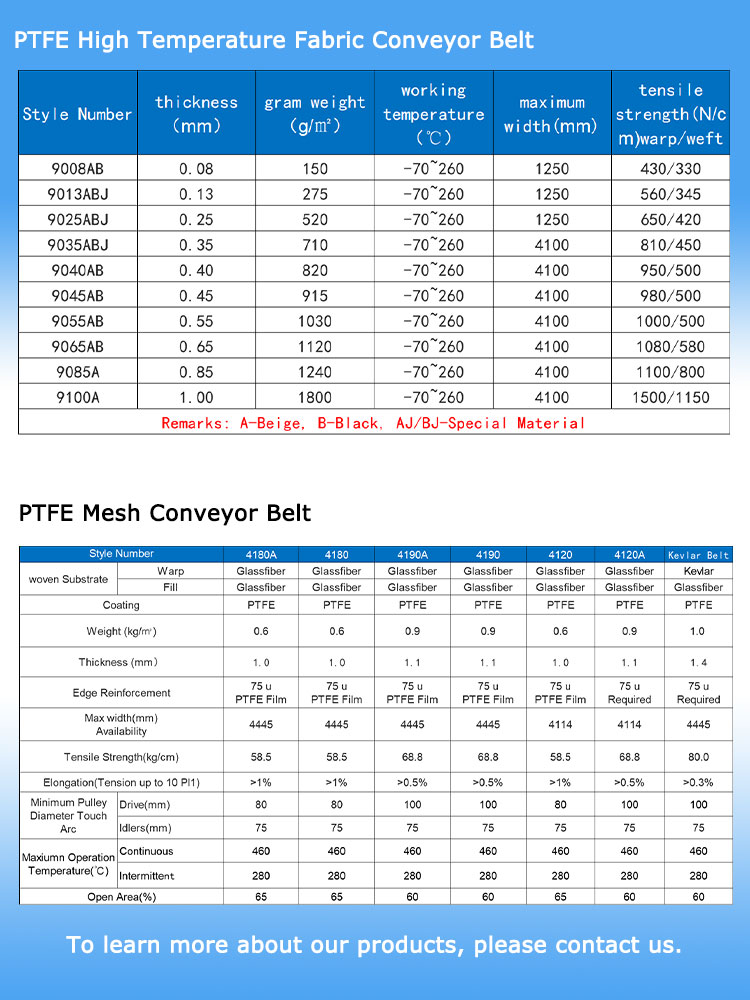

| Products Presentation/Parameters | |

| Company | Guangzhou Yonghang Transmission Belt Co., Ltd. |

| Product | PTFE Conveyor Belt |

| Project | Result |

| Material | PTFE |

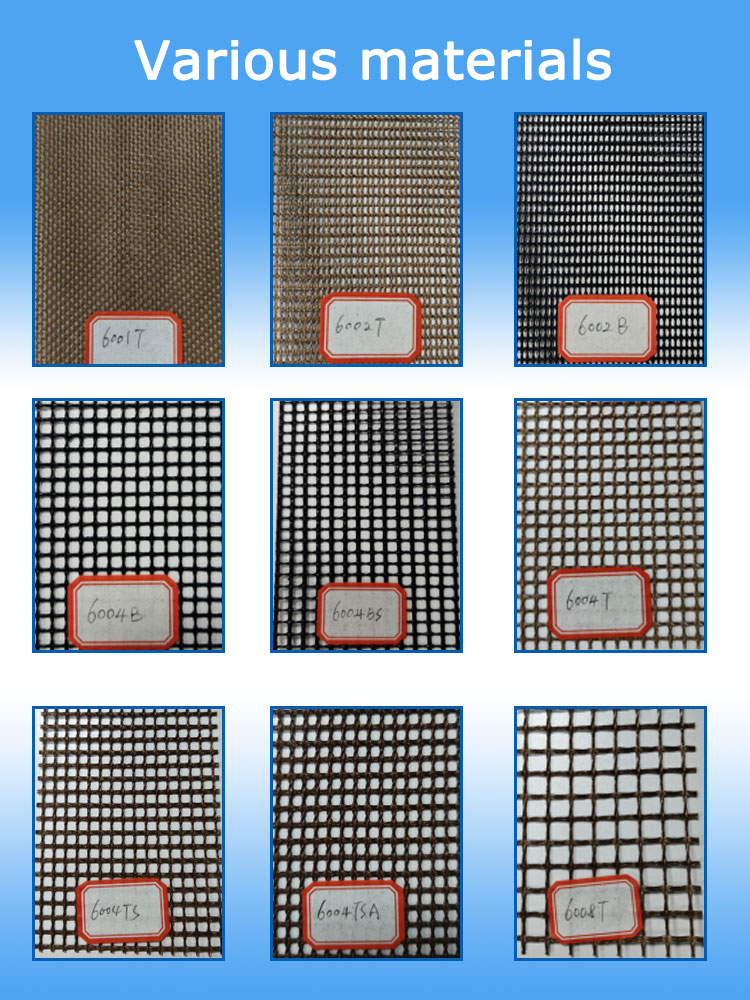

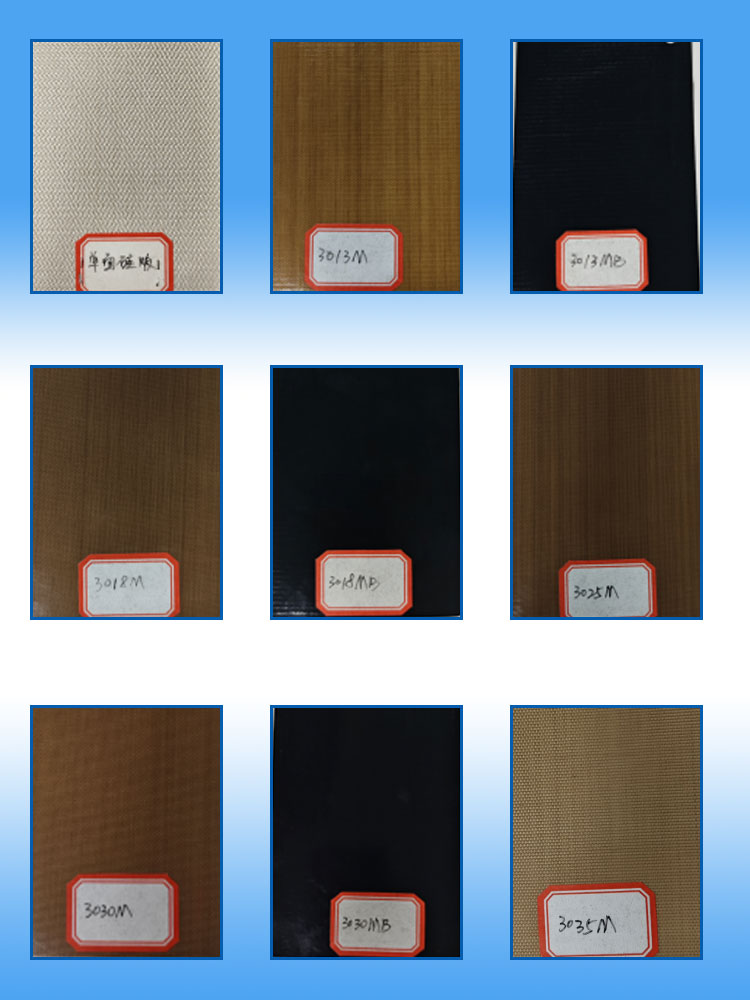

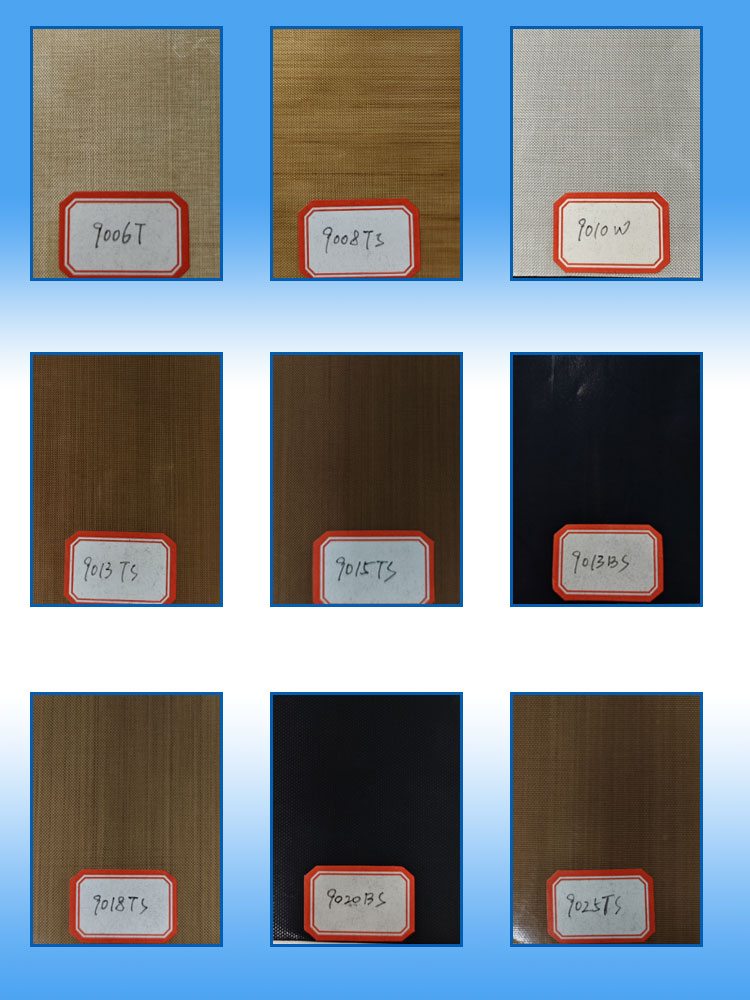

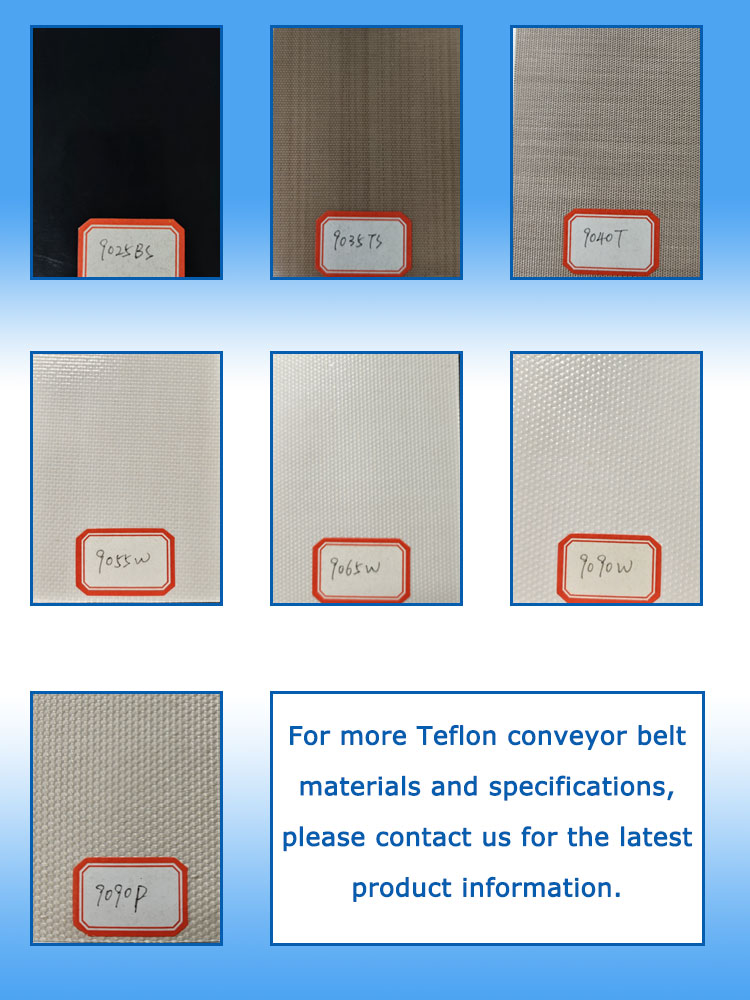

| Color : | white/light brown/black |

| Size: | ODM OEM |

| 300-4200mm. | |

| Thickness: | 0.2-1.35mm. |

| Mesh: | 0.5-10 mm Quadrilateral (4X4 mm,1X1 mm etc.). |

| Applications | “Kevlar” can be customized according to customers' requirements. |

| Weight (kg/㎡) | Length**Thickness*1.3 |

| Joint | bullnose flexible joints, steel buckle joints,butt joints, lap joints, thinned lap joints, steel buckle joints and so on. |

| Working temperature | ﹣70°—350° |

About Teflon belts

The complete series of PTFE Convey belts, including grids and planes, edge wrapping, adding buttons, etc., nose-shaped joint, steel snap joint, sewing thread wrapped fabric joint, etc. PTFE usage temperature range from -70° to 350°.

Teflon belt, also known as Teflon mesh belt, PTFE conveyor belt, is an industrial conveyor belt made of glass fiber cloth coated with polytetrafluoroethylene (PTFE) resin. It is mainly used in textile printing and dyeing drying, food baking transmission, ultraviolet curing equipment, pharmaceutical sterilization production line and electronic and electrical manufacturing, etc. It is suitable for high temperature, corrosive environment of the material conveying needs.

The product's temperature resistance ranges from -70℃ to 350℃, with chemical corrosion resistance, anti-adhesion, breathable and flame retardant properties, outstanding mechanical strength and dimensional stability. Its mesh specification covers 1×1mm to 10×10mm, the weaving structure contains single weft and double weft process, and the bandwidth and edge joints can be customized according to the needs of the equipment, such as bullnose flexible joints, steel buckle joints, and so on. As a non-standardized industrial component, it supports individual structural design and material selection, such as Kevlar composite edging or food-grade safety coating.

Teflon Features:

Resistant to high and low temperatures -70℃-350℃. Weather resistant, anti-aging, long life cycle.

- Anti-adhesion, easy to clean.

- Resistant to all kinds of strong acid and alkali corrosion, chemical resistance, non-toxic.

- Dimensional stability, ductility coefficient less than 5 ‰, high strength, with good mechanical properties.

- Resistant to bending fatigue, can be used for smaller wheel diameter.

- Fire retardant, with permeability, reduce heat loss, improve drying efficiency.

Applications:

A: Textile, printing and dyeing: printing drying, bleaching and dyeing cloth drying, fabric shrinkage drying, non-woven fabric drying and other drying channel, drying room conveyor belt.

B: screen, printing: loose drying machine, offset printing machine, UV series of light solid machine, paper over oil drying, ultraviolet drying, plastic products screen printing drying and other drying channel, drying room conveyor belt.

C: Other items: high-frequency drying, microwave drying, various types of food freezing and defrosting, baking, packaging items heat shrinkage, general moisture content of the items drying, rapid drying of the melt-type ink, such as drying room guide belt.

Where the need for hot air flow occasions and thermal processing transmission conditions, are suitable for the use of Teflon mesh belt

Contact Details