Polyurethane&PU V belt manufacturers From China | Yonghang

Polyurethane&PU V belt made of PU and TPE are available in various Shore hardnesses and diameters for conveying andpower-transmission applications. Many belts are food-approved and have various special properties for particularly demanding applications.

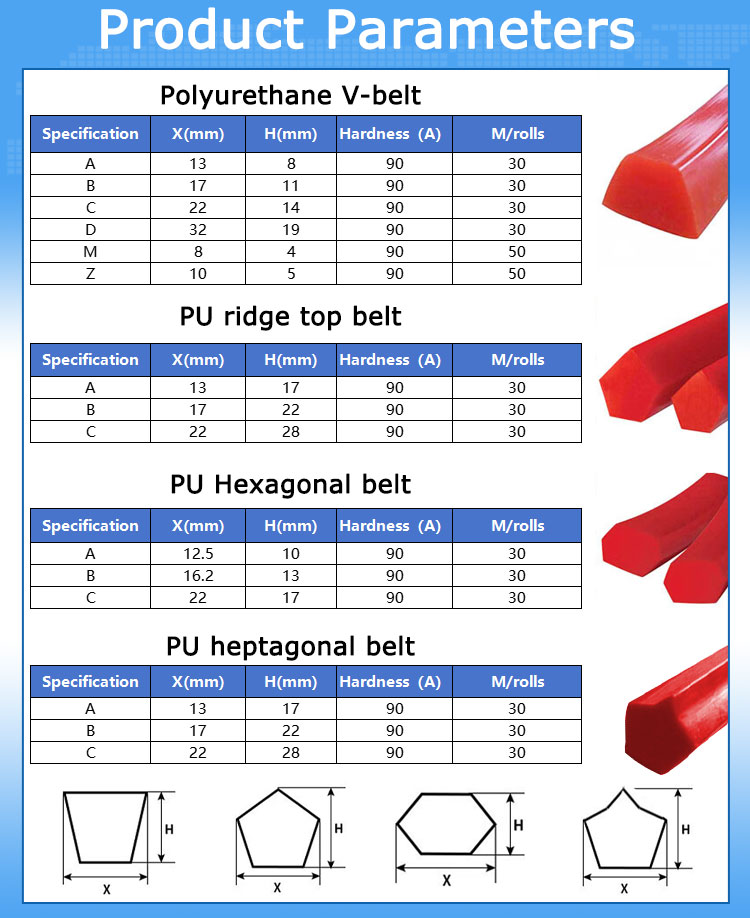

| Auxiliary table /Quick reference for V-belts | ||||||||

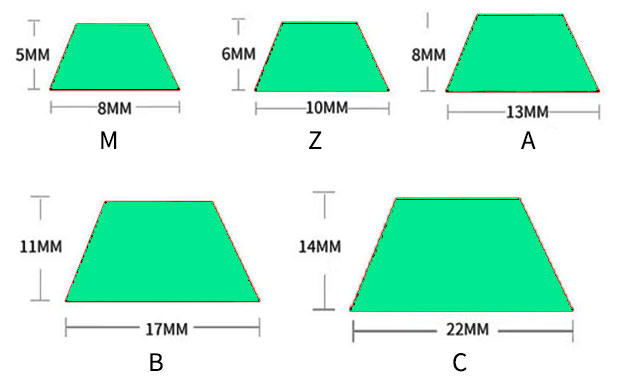

| Profile according to DIN 2215 | 6 | 8 | 10 | 13 | 17 | 22 | 32 | |

| Profile according to IS04184 | Y | M | Z | A | B | C | D | |

| Upper width b(mm) | 6 | 8 | 10 | 13 | 17 | 22 | 32 | |

| Height h (mm) | 4 | 5 | 6 | 8 | 11 | 14 | 20 | |

| Calculation of the blt length La and Lw if Li is determined or known | La=Li+ La=Lw+ | 25 | 31 | 38 | 50 | 69 | 88 | 126 |

| 10 | 12 | 16 | 20 | 29 | 30 | 51 | ||

| La=outside length Lw=efective length/cut length Li=inside length | LW=Li+ LW=La- | 15 | 19 | 22 | 30 | 40 | 58 | 75 |

| 10 | 12 | 16 | 20 | 29 | 30 | 51 | ||

| The recommended pretension has to be considered in addition | ||||||||

Product Introduction

PU V-belts

Weldable V-belts made of PU and TPE are available in various Shore hardnesses and diameters for conveying and

power-transmission applications. Many belts are food-approved and have various special properties for particularly

demanding applications.

Allowing you to control the amount of manufacturing input for your products and projects, we can adapt to your unique business needs. With over 20 years’experience our technical specialists can manufacture 65A,70A,75A, 85A, 90A, 95A, 40D,55D, 65D & 75D from our standard high performance polyurethane materials that we carry in stock.

Alternatively, we can also rapidly supply polyurethane products in any specific desired hardness (+/- 2 Shore hardness) points between 40A & 80D, with standard colours available in Red, Black, White,Orange, Yellow and Blue

Typical industries are: Food, logistics, printing & paper, packaging, building materials and much more.

polyurethane ( PU ) v-belts are available with or without a reinforcement of polyester, kevlar, steel,Aramidor or fiberglass

Coated V-belts

Coatings on V-belts allow to achieve target material properties, e.g. better grip,accumulation or release on a durable base belt. YONGHANG offers various coating materials, hence we can design belts with optimal features for your application.

Product Information

| Description | Dimension mm | Tolerance=mm |

| V-belts | 0-Width Height | |

| Type PU65A | 6-8-10-13-17-22 (Y-M-Z-A-B-C) | -0,5 +0,5 |

| Type PU75A | 6-8-10-13-17-22-32 (Y-M-Z-A-B-C-D) | -0,5 +0,5 |

| Type PU80A | 6-8-10-13-17-22-32 (Y-M-Z-A-B-C-D) | -0,5 +0,5 |

| Type PU85A | 6-8-10-13-17-22-32 (Y-M-Z-A-B-C-D) | -0,5 +0,5 |

| Type PU90A | 8-10-13-17-22-32 (M-Z-A-B-C-D) | -0,5 +0,5 |

| Type TPE40D | 8-10-13-17-22 (M-Z-A-B-C) | -0,5 +0,5 |

| Type TPE55D | 8-10-13-17-22 (M-Z-A-B-C) | -0,5 +0,5 |

| Manufacturing tolerances for tailoring | |

| Production lengt | Production tolerance |

| 150-1000 mm | ±2mm |

| 1001-4000mm | ±3mm |

| 4001-10000 mm | ±5mm |

| über 10000 | ±10 mm |

| Production width | Production tolerance |

| <100mm | ±1.0 mm |

| >100mm | ±2.0mm |

| thickness | Production tolerance |

| 0,9/1,0/1,2/1,6/2,0/3,0/4,0mm | ±10% of the belt thickness |

| Contact customer service if more strict tolerances are required. | |

Company Advantages

Certifications and Patents

Frequently Asked Questions about polyurethane ( PU ) v-belts price

Chemical characteristics of PU and TPE

General

Thermoplastic material can be used in a variety of applications where there is interaction with various chemicals. Chemical resistance depends on the period of exposure, the temperature, the quantity, the concentration and the type of the chemical substance. It is therefore difffcult in any case to make a clear distinction between the effects described below. In the case of chemical degradation of polyurethane the chemical reaction results in cleavage of the molecular chains. In the course of degradation, polyurethane loses strength, and in extreme cases this can lead to disintegration of the part.

For critical applications, a detailed resistance test considering both swelling and the affect on mechanical properties is recommended.

Swelling

Swelling is the fundamental physical process of the absorption of liquid substances by a solid. In this process, the substance enters into the material without chemical interaction. This results in an increase in volume and weight with a corresponding reduction in mechanical values. After evaporation a reduction in swelling occurs and the original properties of the product are almost completely restored.

Swelling is a reversible process. By using reinforcements in the polyurethane, for example polyester or aramid cords, you can almost avoid this mechanical impact on the material.

Hydrolysis

resistance If polyester-based polyurethanes are exposed for lengthy periods to hot water, moisture vapour or tropical climates, an irreversible break-down of the polyester chains occurs through hydrolysis. This results in a reduction in mechanical properties. This effect is more marked in ffexible grades, where the polyester content is correspondingly higher than in the harder formulations. Degradation of polyester-based polyurethanes is however rarely experienced at room temperature. Because of its chemical structure, polyester-based polyurethanes are much more resistant to hydrolytic degradation.

Microbiological

resistance When using polyester-based thermoplastic polyurethane under climatic conditions of high heat and humidity, parts can be damaged by microbiological attack. In particular, microorganisms producing enzymes are able to affect the molecule chains of polyester-based TPU. The microbiological attack initially becomes visible as discoloration. Subsequently, surface cracks occur which enable the microbes to penetrate deeper and to cause a complete destruction of the TPU.

Contact Details