Quality Mine vibrating screen belt HTD 20M rubber timing belts Manufacturer | Yonghang

Mine vibrating screen belt HTD 20M rubber timing belts compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Yonghang summarizes the defects of past products, and continuously improves them. The specifications of Mine vibrating screen belt HTD 20M rubber timing belts can be customized according to your needs.

Mine vibrating screen belt

Mine vibrating screen belt

In the core operations of mining production, the stable operation of vibrating screens directly impacts ore sorting efficiency and production continuity. As a critical transmission component, the selection and quality of mine vibrating screen belts are paramount in determining equipment performance.

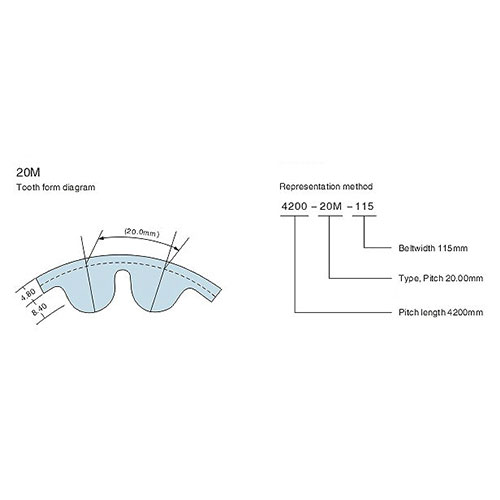

Mine vibrating screen belts encompass multiple tooth profiles including XH, XXH, 14M, and 20M, with numerous popular specifications: from 1000XXH, 1050XXH, 1200XXH, to 1400XXH, 1463XXH, 1600XXH, and further to 14M2310, 20M3000, and 20M5000. Mining equipment specifications vary widely, and standardized products may not fit perfectly. At Yonghang, we offer manufacturers the ability to cut belts to any width, customizing dimensions based on actual equipment requirements to avoid secondary purchases due to specification mismatches.

Specifications and Dimensions Table

| 14M | 20M | |||

| Model | Model | Model | Model | Model |

| 14M 826 | 14M 1358 | 14M 1792 | 14M 2450 | 20M |

| 14M 840 | 14M 1400 | 14M 1806 | 14M 2590 | 2000 |

| 14M 896 | 14M 1414 | 14M 1820 | 14M 2604 | 2140 |

| 14M 924 | 14M 1428 | 14M 1848 | 14M 2660 | 2200 |

| 14M 966 | 14M 1442 | 14M 1862 | 14M 2758 | 2240 |

| 14M 1008 | 14M 1456 | 14M 1890 | 14M 2800 | 2280 |

| 14M 1036 | 14M 1470 | 14M 1904 | 14M 2912 | 2300 |

| 14M 1050 | 14M 1484 | 14M 1932 | 14M 2940 | 2500 |

| 14M 1064 | 14M 1512 | 14M 1946 | 14M 3150 | 2760 |

| 14M 1092 | 14M 1568 | 14M 1960 | 14M 3360 | 2800 |

| 14M 1120 | 14M 1540 | 14M 2002 | 14M 3416 | 2880 |

| 14M 1148 | 14M 1610 | 14M 2044 | 14M 3500 | 3000 |

| 14M 1176 | 14M 1638 | 14M 2072 | 14M 3850 | 3200 |

| 14M 1190 | 14M 1652 | 14M 2100 | 14M 4004 | 3220 |

| 14M 1232 | 14M 1666 | 14M 2156 | 14M 4326 | 3400 |

| 14M 1246 | 14M 1680 | 14M 2170 | 14M 4578 | 3420 |

| 14M 1260 | 14M 1736 | 14M 2212 | 14M 4760 | 3800 |

| 14M 1288 | 14M 1750 | 14M 2240 | 14M 4956 | 4200 |

| 14M 1316 | 14M 1764 | 14M 2310 | 14M 5320 | |

| 14M 1344 | 14M 1778 | 14M 2380 | ||

Advantages

rubber 20M timing belts adheres to strict standards and specifications;

Rubber raw materials must pass aging resistance and tear strength tests, with fiber reinforcement tensile strength ≥300 MPa.

The tooth profile is precision-molded as a single unit and undergoes rigorous dimensional verification, with pitch deviation controlled within an industry-leading minimal range.

Verified through tens of thousands of cyclic vibration tests, it maintains structural stability even under prolonged high-frequency vibration conditions.

About Yonghang

Frequently Asked Questions about rubber belt

Contact Details