LC361LC363LC333LC636 Carding machine timing belts

LC361LC363LC333LC636 Carding machine timing belts

Belt Part No: 25T10-3550+97 cleats /Applications:LC 361/LC363

Part No: 25T10-3000+82 cleats Applications:LC333 Belt

Belt Part No: 25T10-3770+103 cleats Applications:LC636 Belt

PU timing belt with cleats

Applications:Rieter LC 361/LC363, LC 333/LC333, LC 636/LC636;

Carding machine timing belts are typically composed of a polyurethane base and steel cord, with custom materials available upon request. Special steel cords include aramid (Kevlar).

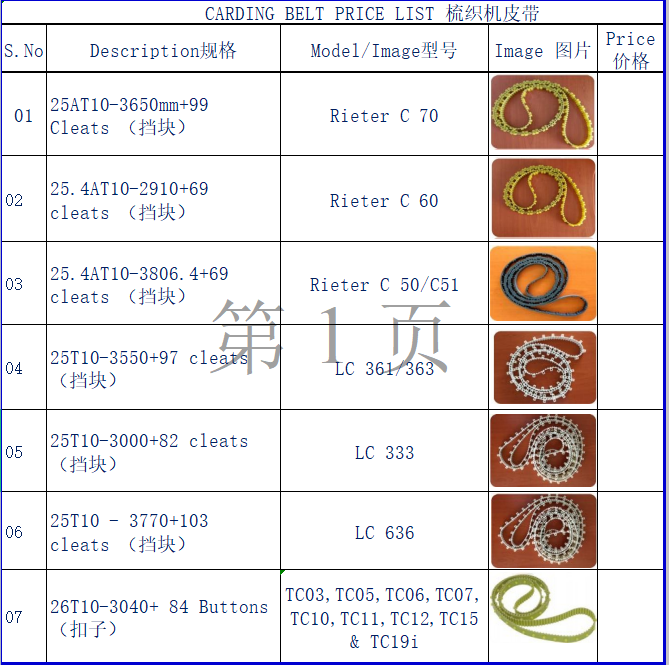

Carding machine timing belts are potential replacement belts. Carding machine belts include AT10 and T10, as shown in the table below.

Applications include Rieter C 70/C70, C 60/C60, C 50/C51; LC 361/LC363, LC 333/LC333, LC 636/LC636; Trützschler TC03, TC05, TC06, TC07, TC10, TC11, TC12, TC15, TC19i, TC19i.

The most common widths for carding timing belts are 25 mm and 26 mm, with custom dimensions (length, width, and pitch) available upon request.

Carding timing belts feature custom profiles and specialized teeth. Their advantages include high abrasion resistance, premium quality, and extended service life.

Carding is an essential process in the textile industry, involving the separation, cleaning, and alignment of fibers to form continuous webs or slivers. The carding belt is one of the critical components of a carding machine. But what exactly is a carding belt? How does it function?

What is a carding machine timing belt?

A carding belt is a specialized belt used within carding machines to transport fibers throughout various stages of the carding process. It is manufactured from premium materials such as rubber or synthetic fibers to ensure durability and extended service life.

How does a carding machine belt function?

The carding belt is responsible for conveying fibers from the feed section to the doffer section of the carding machine. It moves at precise speeds to ensure consistent and uniform fiber transport. The belt's surface is engineered to grip fibers and prevent slippage, enabling efficient carding.

Key Features of Carding Machine Belts

Carding machine belts possess several critical characteristics that make them indispensable components in the carding process:

Durability: Designed to withstand the demanding conditions of carding operations, including high speeds and constant tension.

High Friction: The belt surface is engineered to provide high friction, ensuring a firm grip on fibers and preventing slippage.

Uniformity: Manufactured to precise specifications, carding belts ensure even fiber conveyance and maintain the quality of carded material.

Low Maintenance: With proper care and maintenance, carding belts extend service life, reducing the need for frequent replacements.

Advantages of Using Carding Belts

Employing high-quality carding belts delivers the following benefits:

Enhanced Efficiency: Carding machine timing belts enable precise, uniform fiber conveyance, boosting overall carding process efficiency.

Improved Fiber Quality: Consistent fiber delivery ensures uniformity in carded material, leading to higher-quality end products.

Reduced Downtime: The durability and reliability of carding belts minimize production interruptions caused by belt failures, ensuring uninterrupted operation.

Cost-Efficiency: Investing in high-quality carding machine belts reduces the need for frequent replacements, delivering long-term cost savings.

In summary, carding machine timing belts are critical components in the carding process, facilitating efficient fiber transportation. Their durability, high friction, and uniformity contribute to enhanced efficiency, improved fiber quality, and reduced downtime. By investing in high-quality carding machine timing belts, textile manufacturers can optimize their carding operations and achieve higher-quality end products.

Contact Details