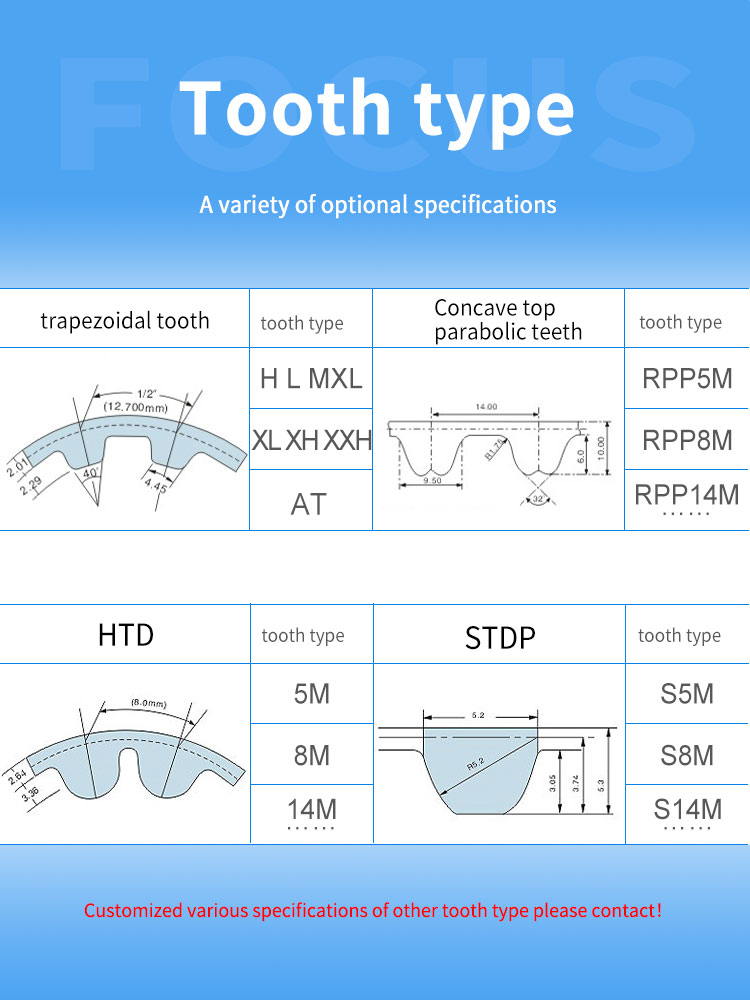

PU timing belt HTD STD S3M 5M S5M 8M T5 T10 AT5 AT10 AT20 H XH Polyurethane Meld Urethane Kevlar Cord Timing belts

The Kevlar Cord PU open/ seamless timing belt are made of high-strength polymers and reinforced materials, which make them mechanicalforth of all industrial applications. We can help you optimize your design and recommend the right solution, including custom-made polyurethane syncs trips and surfaces plus PU/holes /rubber/sponge/baffle/cleats, etc

Detailed

kevlar reinforced timing belts is usually in application areas where steel wire timing belts cannot meet the requirements,in the process of using, polyurethane belts experience tensile forces. Relying solely on polyurethane to withstand this stress is insufficient, as it would cause the belt to stretch. Once elongation exceeds the pulley's adjustment range, the belt becomes unusable. Therefore, we incorporate Kevlar core strands into the polyurethane synchronous belt. These Kevlar strands serve as the belt's tensile reinforcement, transmitting power while ensuring the pitch remains constant during operation. Multiple strands of Kevlar fiber cord are spirally wound across the belt width, positioned along the belt's pitch line. This design delivers high tensile strength and resistance to flexural fatigue, ensuring excellent dimensional stability. With minimal manufacturing tolerances, it guarantees precision in both thickness and length!

Length and width range

| type | AT5 | AT10 | AT20 | T5 | T10 | T20 | H | XH | L | XL |

| length(min)mm | 100 | 300 | 800 | 80 | 250 | 800 | 317.5 | 1500 | 381 | 248.92 |

| width scope(mm) | 3-500 | 3-500 | 10-500 | 3-500 | 5-500 | 20-400 | 5-400 | 20-200 | 5-500 | 3-500 |

| type | 3M | 5M | 8M | 14M | R5M | R8M | R14M | S3M | S8M | S14M |

| length(min)mm | 60 | 90 | 400 | 800 | 300 | 400 | 800 | 60 | 400 | 800 |

| width scope(mm) | 3-500 | 5-500 | 10-500 | 20-200 | 5-500 | 10-500 | 20-200 | 3-500 | 10-500 | 20-200 |

Truly Seamless (moulded)

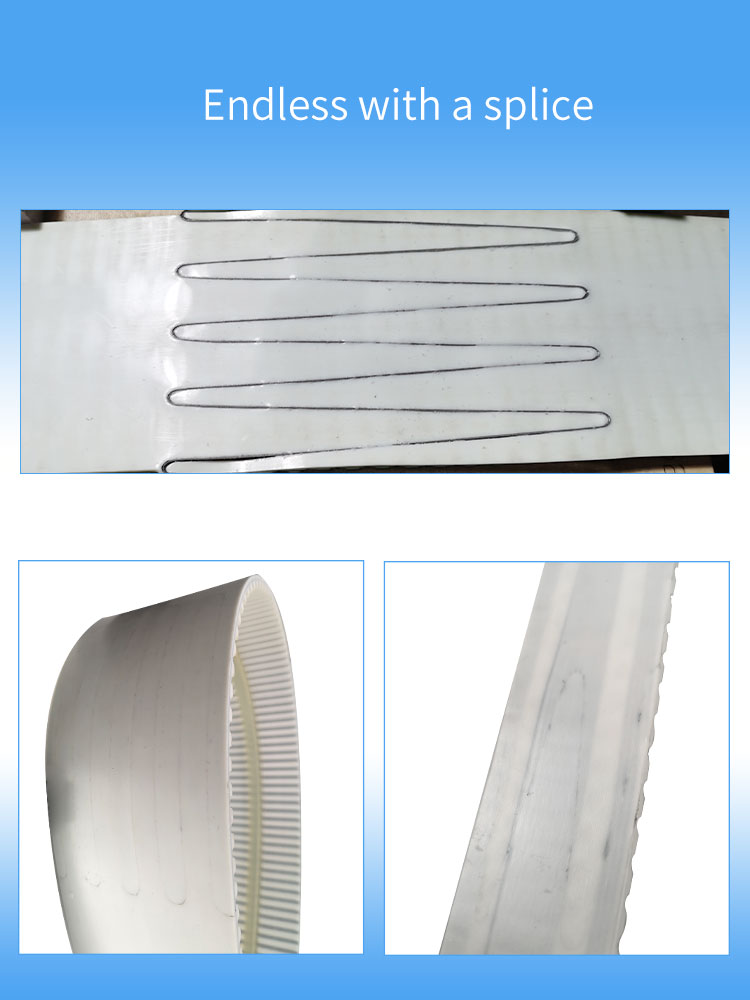

Endless with joint

Open Ended

Pin join

Reducing Sliding Resistance

Nylon Fabric on Tooth Side (PAZ / NFT)

Nylon Fabric on Back Side (PAR / NFB)

Nylon Fabric on Tooth Side & Back Side (PAZ/PAR)

Colors:

Black, White, Light Yellow, Red, etc.

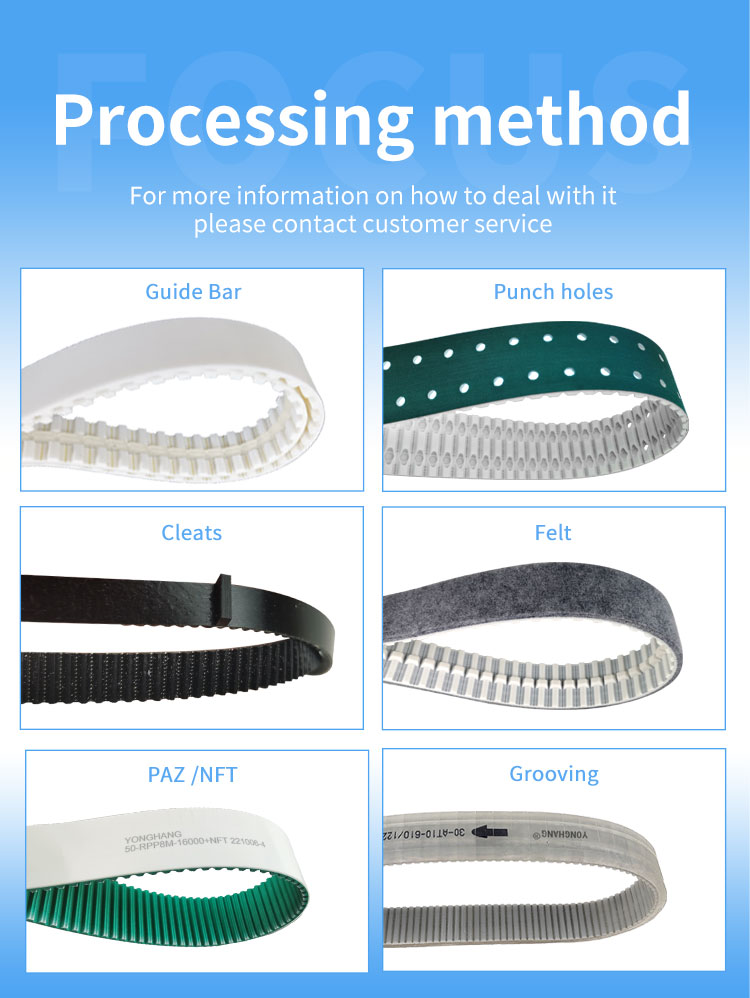

special processing

All PU synchronous belts listed above can be customized in width and length. Additional processing options include adding green fabric to the tooth surface and back, applying patterns, adding red, green, or black rubber, slotting, adding stop blocks, drilling holes, adding guide strips, and incorporating blue fabric sponge.

Advantage

1. Exceptional Tensile Strength and Lightweight Design

High Strength: Kevlar fiber boasts a specific strength (strength-to-weight ratio) over five times that of steel wire. This enables Kevlar timing belts to withstand extremely high tensile forces without breaking.

Lightweight: Kevlar fiber has a significantly lower density than steel wire, resulting in a lighter overall belt weight. This is particularly crucial for high-speed applications, as reduced mass minimizes inertia, lowers load on shafts and bearings, and enables faster acceleration/deceleration and higher rotational speeds.

2. Exceptional Flexibility and Small Minimum Bending Radius

Compared to steel-cord belts, Kevlar belts are exceptionally flexible. This allows them to operate on smaller pulley diameters, enabling more compact drive designs with reduced vibration and noise during transmission—ideal for precision drive applications.

3. Outstanding Dimensional Stability

Kevlar fibers exhibit extremely low elongation under prolonged tension.

4. Superior Fatigue Resistance and Impact Protection

Kevlar fibers exhibit excellent resistance to flex fatigue, enduring repeated bending and stretching to extend belt lifespan. Their fiber structure absorbs impact energy, providing enhanced protection during sudden load changes.

5. Corrosion and Chemical Resistance

Kevlar fibers resist rust and corrosion, making them ideal for humid, acidic, alkaline, or other corrosive environments where steel-cored belts are prone to rust damage.

6. Non-metallic, Electrically Insulating, and Non-magnetic

As a non-metallic material, Kevlar synchronous belts incur no eddy current losses and are suitable for applications requiring avoidance of magnetic interference (e.g., MRI equipment).

Being electrically insulating, they can be used in drive systems necessitating electrical isolation.It is usually applied in combination with anti-static polyurethane materials.

What's the difference between steel cord timing belts and Kevlar timing belts?

please click

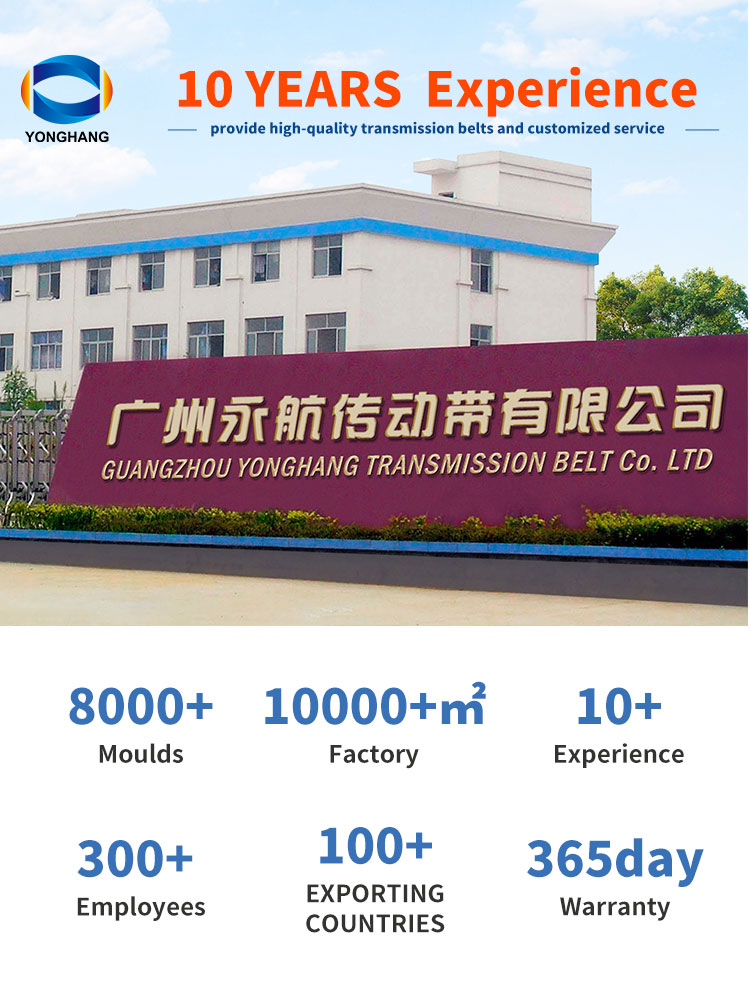

Contact Details