HTD8M-3280-50 rubber coated timing belt for strip the plastic machine

The Yonghang strip the plastic machine belts are made of high-quality neoprene rubber - comparable to LINATEX.

This specially developed rubber quality guarantees constant high friction and excellent wear resistance.

All backings can be modified mechanically on request.

YONGHANGTechnics specially customizes belts according to your requirements like grooves, slots, perforations etc.

Please contact us direct for more information regarding your specific requirements.

HTD8M-3280-50+15 rubber coated timing belt Specifically designed for plastic stripping machines—the core equipment in the plastic recycling industry,

Advantage

High Torque Drive, Powerful and Stable Operation

Featuring HTD (High Torque Drive) 8M curved tooth design, it offers greater contact area and more even load distribution compared to traditional trapezoidal teeth, significantly enhancing torque transmission capability. This ensures the plastic peeling machine maintains stable and efficient power output even when encountering hard materials or sudden load surges, completely eliminating tooth skipping and slippage.

Specialized Rubber Coating, Exceptional Grip and Wear Resistance

Featuring a specialized wear-resistant rubber coating, this surface delivers an exceptionally high coefficient of friction and outstanding abrasion resistance. It effectively withstands wear from plastic debris and sharp particles, as well as physical deterioration caused by prolonged high-load operation, significantly extending the belt's service life.

High-strength load-bearing layer, impact-resistant and fatigue-resistant

Integrated high-strength, low-elongation glass fiber cables or aramid fibers form the reinforcement layer, imparting exceptional dimensional stability and tensile strength to the belt.

Outstanding resistance to flex fatigue and impact allows it to effortlessly absorb vibrations and shocks generated during plastic peeling machine operations, ensuring smoother and more reliable performance.

Precision Synchronization Ensures Production Consistency

Precise manufacturing processes guarantee accurate pitch dimensions for each gear tooth, achieving perfect meshing with equipment gears. This ensures constant synchronized rotation of the plastic peeling machine's feed rollers or cutting discs, thereby guaranteeing uniform peeling thickness and consistent processing quality. This enhances the quality and output rate of the final product.

Technical specification

Color : black etc

Size:8M-3280-50+15 rubber

Length:3280

Width:50

Thickness:21total thickness

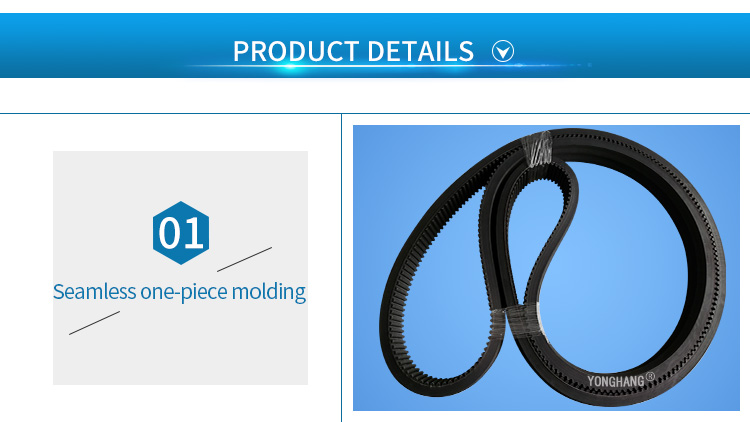

Structure: Closed-loop seamless

Material:Vulcanized rubber

Surface: Wear-resistant rubber coating

Whether standard parts: Standard

Process (construction): Vulcanized rubber belt punching ,Single row hole, multi - emptying evenly distributed

Performance: Excellent strong friction wear resistance, oil and corrosion resistance, no lamination, long service life

Applicable Equipment:

Various plastic peelers, shredders, and pelletizers

Other plastic recycling machinery and heavy industrial equipment requiring high-torque, heavy-load transmission.

Contact Details