Yonghangbelt NEW R&D power drive electric climbing robot rubber track belts

In today's era of rapid robotics advancement, electric climbing robots are increasingly becoming indispensable tools for high-altitude operations, industrial inspections, and other fields. A core technology enabling these robots to securely adhere to walls and surfaces, traverse freely, and even overcome obstacles lies in their critical component—rubber tracks.

Rubber tracks are circular track devices composed of rubber combined with metal or fiber materials, specifically engineered to deliver exceptional traction, stability, and adaptability. This article will take you on an in-depth exploration of the material composition, prominent advantages, and diverse application scenarios of rubber tracks used in electric wall-climbing robots.

Rubber Track belts Material and Structure

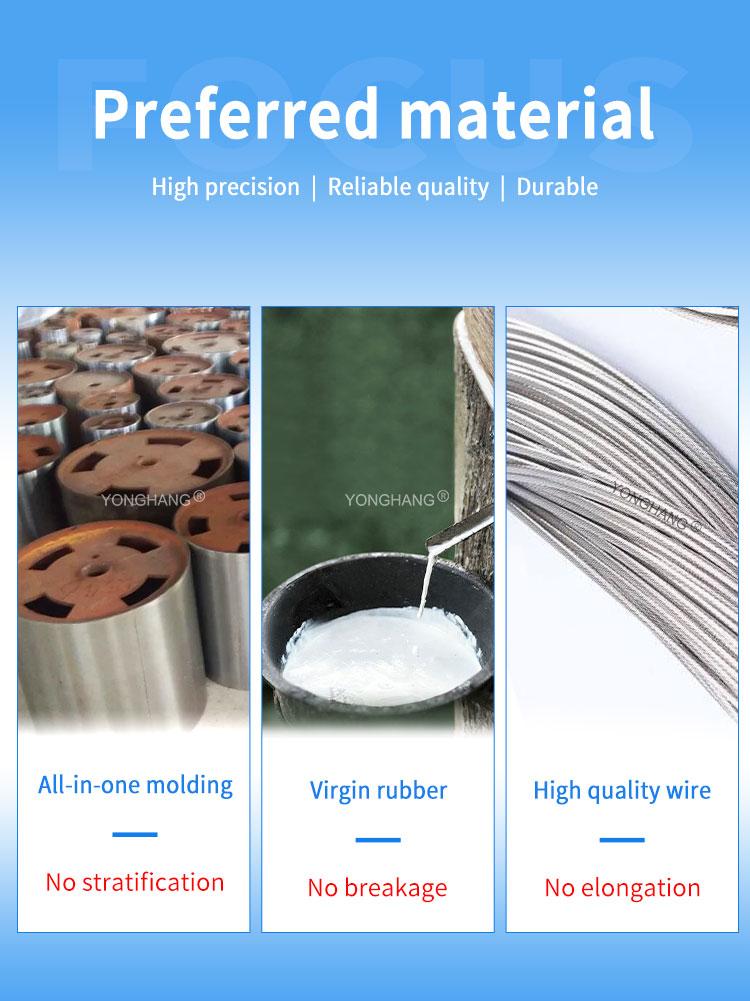

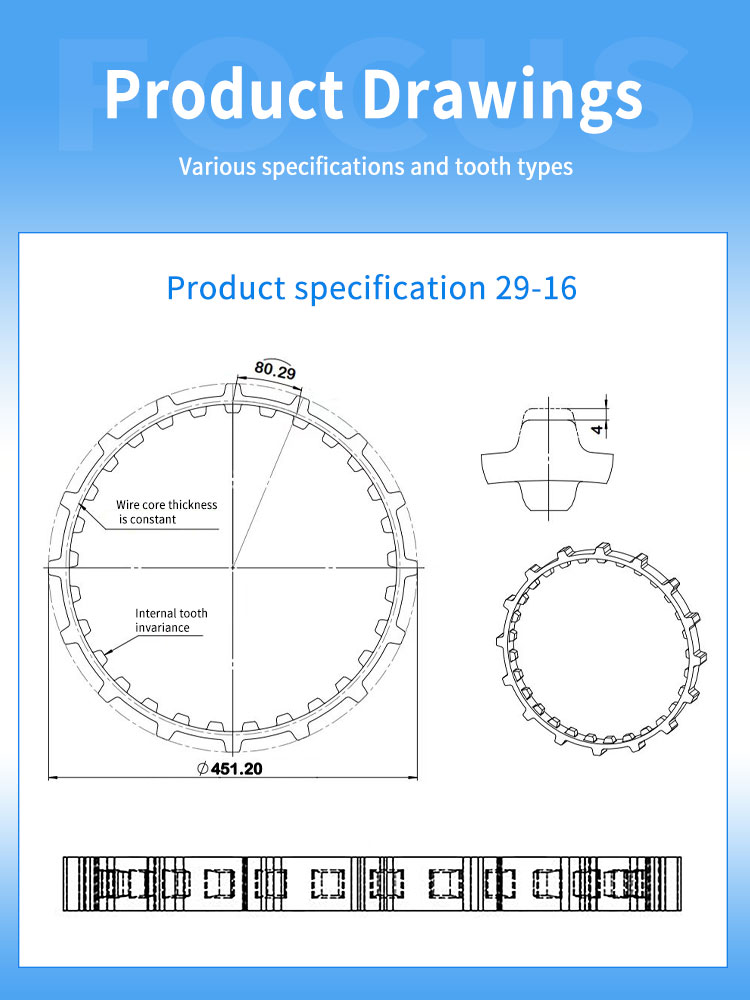

The exceptional performance of electric wall-climbing robot rubber tracks belts stems from meticulous material selection and structural design.

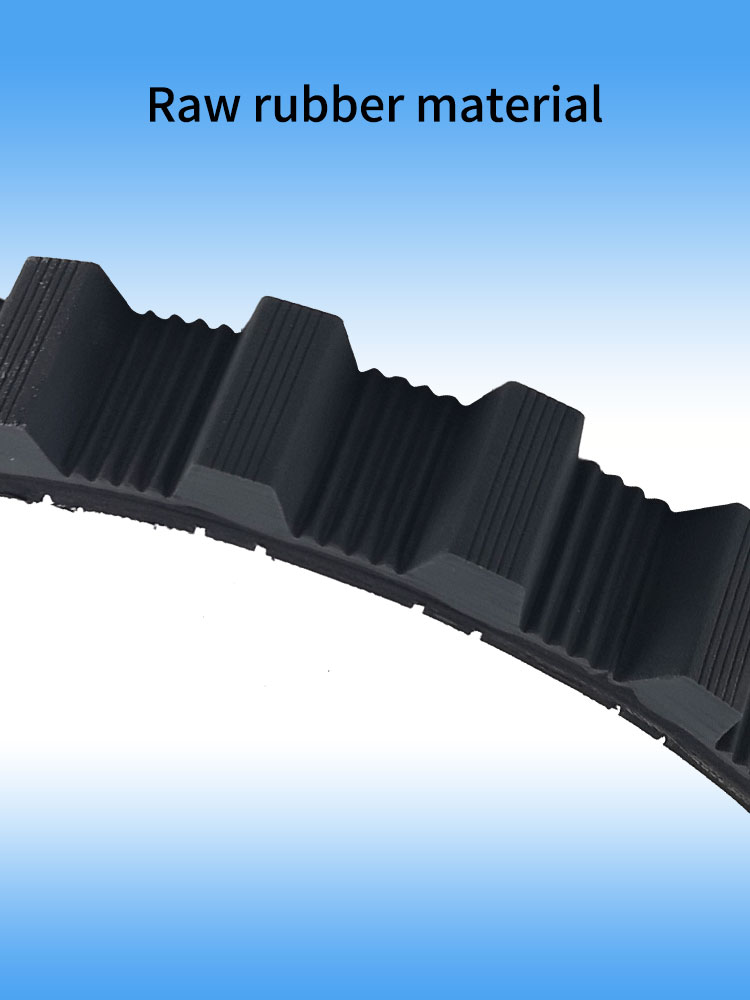

Primary Material: Tracks belts typically utilize neoprene or ethylene propylene diene monomer (EPDM) rubber as the main material. These rubber compounds offer durability and excellent friction properties.

Reinforcement: Glass fiber cords or Kevlar (aramid) fibers are embedded within the rubber as structural reinforcement (strengthening layers). This provides the tracks belts with exceptional tensile strength and dimensional stability, preventing excessive elongation or deformation during load-bearing operation.

Surface Protection: The track teeth are typically covered with highly abrasion-resistant nylon canvas. This protective layer significantly enhances wear resistance and reduces operational noise.

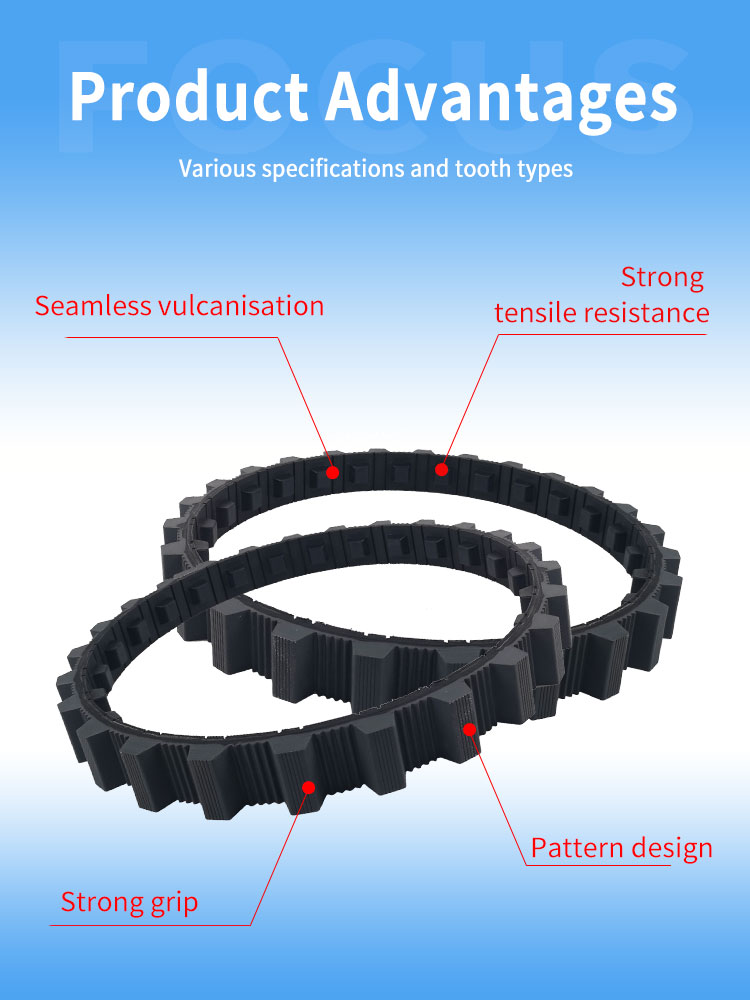

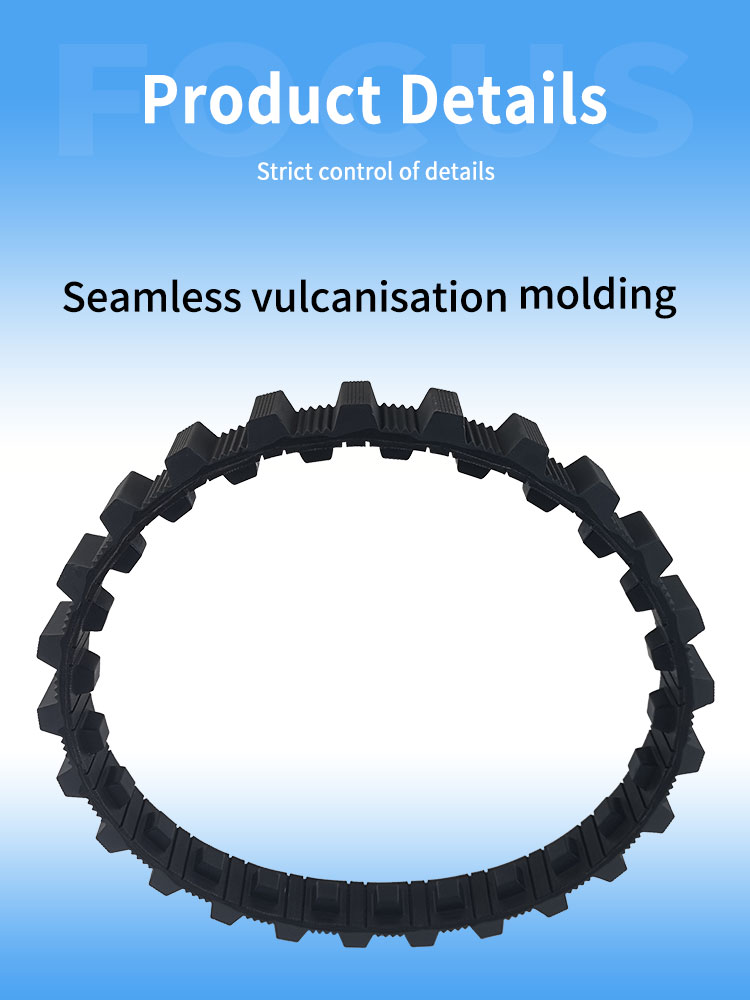

Processing and Design: Advanced seamless vulcanization ensures the track's structural integrity and high strength, preventing delamination during use. Surface tread patterns—such as straight grooves or herringbone designs—are crucial for enhancing traction and slip resistance.

Advantages of Rubber Tracks belts

Compared to tracks belts made of metal or other materials, rubber tracks belts demonstrate multiple significant advantages in wall-climbing robot applications.

Exceptional Adhesion and Traversability: Rubber tracks belts exert low ground pressure, enabling superior wall-hugging capability—crucial for wall-climbing robots utilizing negative pressure or magnetic adhesion principles. Their flexibility allows adaptation to various curved terrains while maintaining excellent ground contact.

Superior Traction and Anti-Slip Performance: Rubber material delivers strong friction. Specially designed anti-slip patterns—such as surface-ground right-angle grooves—create effective gripping angles with walls or stairs, significantly enhancing traction and preventing slippage during incline climbing.

Effective Surface Protection: Rubber's relatively soft texture minimizes damage to contact surfaces like marble, tiles, or wood. This represents an unmatched advantage over steel tracks.

Low Noise and Vibration: Rubber's inherent elasticity absorbs and cushions operational vibrations, ensuring smoother equipment operation with reduced noise levels. This enhances user experience and environmental friendliness.

Lightweight and Corrosion-Resistant: Rubber tracks are inherently lightweight, contributing to reduced overall robot weight. Synthetic rubbers like EPDM also offer excellent chemical resistance and aging resistance, enabling adaptation to more complex working environments.

Industrial Applications of Rubber Tracks Belts

Leveraging the aforementioned advantages, rubber tracks belts play a vital role in intelligent robots across multiple sectors.

Wall-Climbing Inspection and Maintenance Robots: This represents a core application area for rubber tracks belts. Whether performing non-destructive testing on ship hulls, large storage tanks, or bridge structures, or executing maintenance tasks like surface painting, rust removal, and polishing, rubber tracks belts provide robots with a stable and reliable mobility foundation.

Building Access and Logistics Delivery Robots: Robots capable of autonomously navigating stairs to complete the “last-mile” delivery of parcels and takeout rely on flexible rubber tracks belts to conform to stair profiles while maintaining stable ascent.

Specialized Service and Security Robots: In scenarios like firefighting, emergency rescue, and security patrols, robots frequently encounter complex, rugged terrain. Rubber tracks belts excel here with their outstanding terrain traversal capabilities and durability.

Industrial Automation and Smart Warehousing: In automated factories and warehouses, track-based robots used for material handling similarly rely on rubber tracks belts to achieve smooth, low-noise movement, meeting the high standards demanded by modern intelligent spaces.

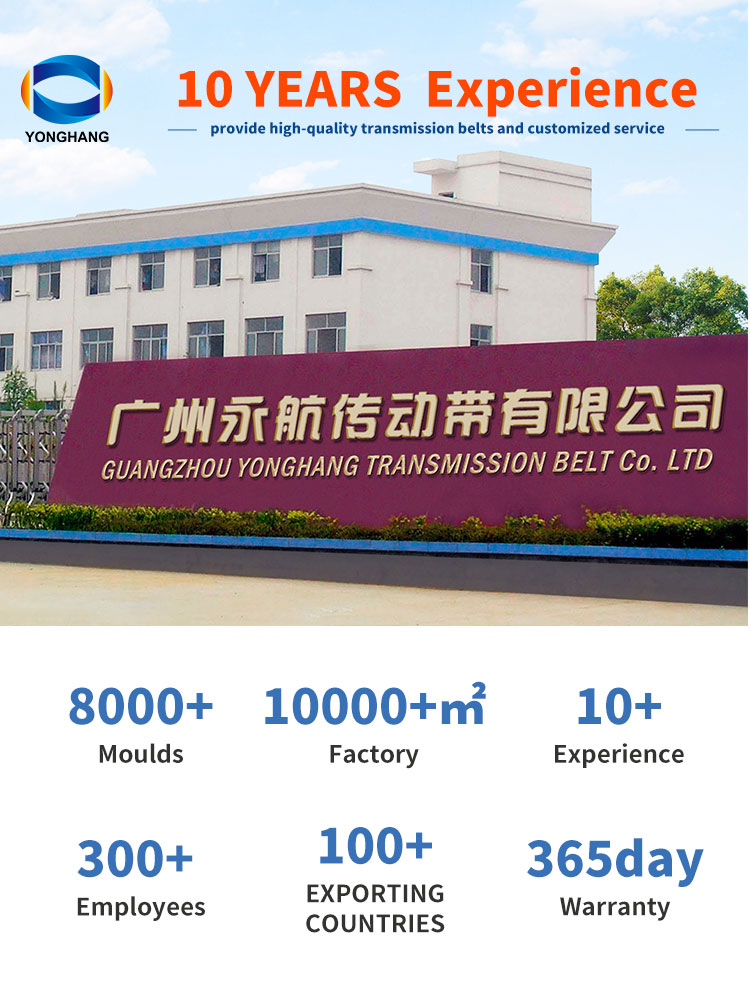

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

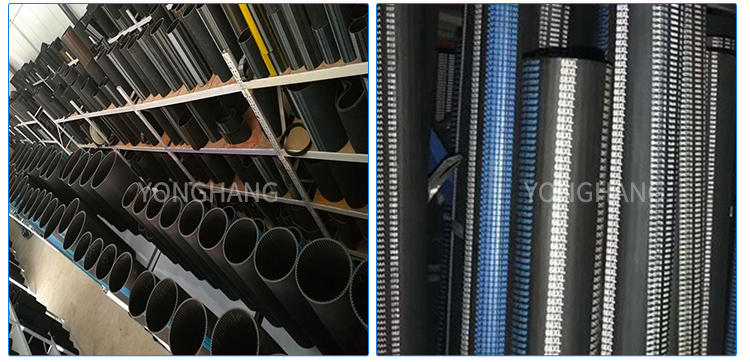

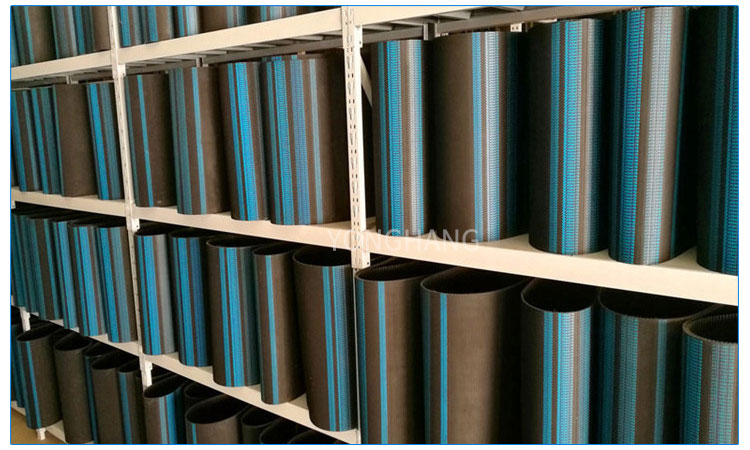

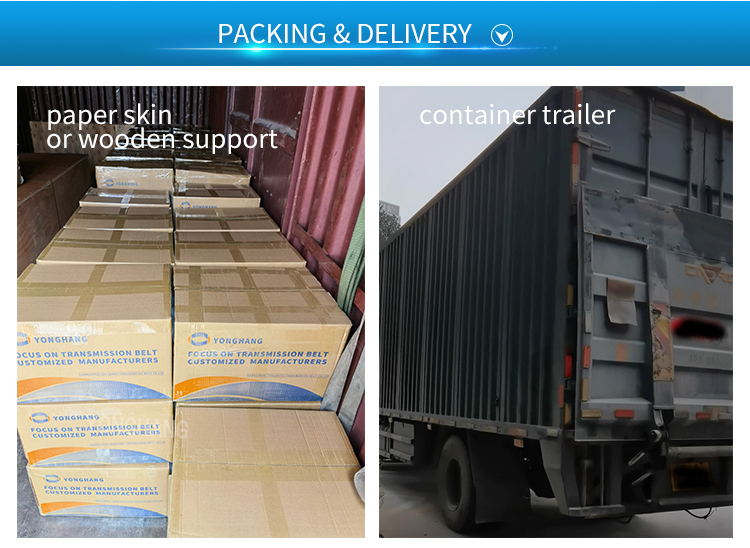

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details