AT3 AT5 AT10 AT15 AT20 Profile PU timing belts wholesaler From China | Yonghang

AT Timing Belt – AT3、AT5、AT10、AT20

AT timing belt is mostly used type in industry. It achieves economical drive solutions in the low to medium performance range.

Wear Resistant

High Efficiency

Low Maintenance

Load Capacity

Product Introduction

AT Timing Belt Description

Compared with T-type timing belt, AT-type synchronous belt is more precise, it is smaller and has higher efficiency in the same transmission ratio, suitable for fast speed (1000~10000r/min) occasions. The width of the top of the tooth is relatively narrow, and the base of the tooth is relatively wide, which reduces the pressure of the top of the tooth and reduces wear.

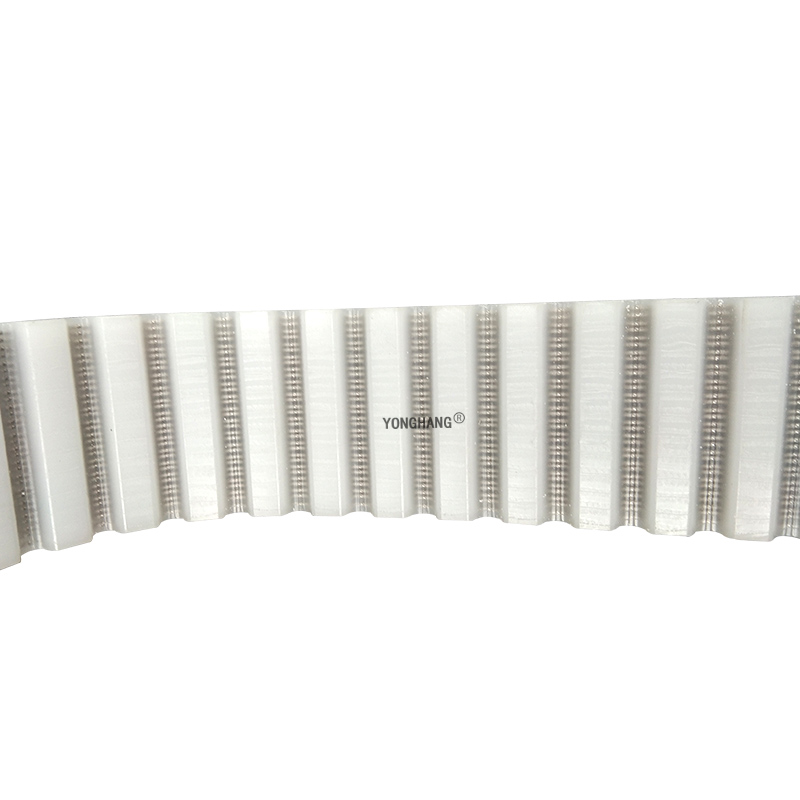

Yonghang mainly offers AT3, AT5, AT10 and AT20 PU timing belt. High wear-resistant material and high strength design, which greatly improve belt life service and reduce replacement frequency

Custom sizes and materials available.

AT Profile PU Timing belt has Good resistance against oil, fats and many chemicals.

AT timing belts only run on AT pulleys.

AT timing belts made of TPU can be welded to endless belts. When welded, the perm. tensile force is

reduced to 50%.

Product Information

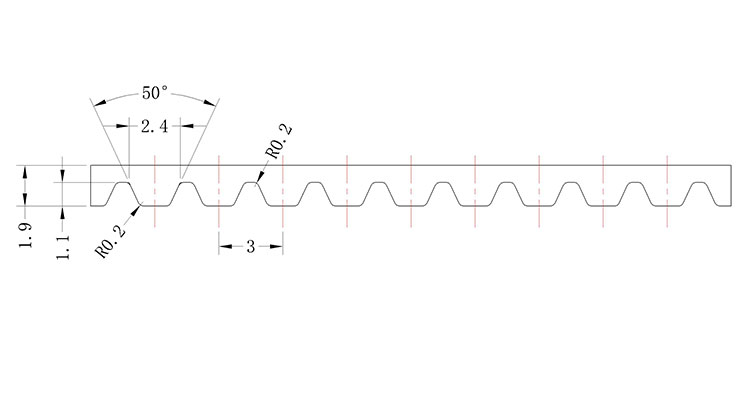

AT3 Profile Tooth figure

Description

Part No 10-AT3-300 Belt Type Truly Endless

Length [mm] 300 Pitch [mm] 3

Width [mm] 10 Number of Teeth 100

Tooth Profile AT Belt Type Closed Loop

| Specifications | |

| Trapezoidal Profile | AT3 |

| Tooth Pitch t [mm] | 3 |

| Base Belt Thickness H [mm] | 0.8 |

| Tooth Height h [mm] | 1.1 |

| Overall Belt Thickness H [mm] | 1.9 |

| Width Tolerance [mm] | +/- 0.5 |

| Length Tolerance [mm] | +/- 0.5 |

| Thickness Tolerance [mm] | +/- 0.2 |

| Hardness | 92 Shore A |

| Body Materials | Polyurethane (PU) |

| Tensile Members | Steel |

| Color | White,Yellow, Black, Gray |

| Minimum of Teeth on Pulley | 15 |

| Minimum Pulley Diameter [mm] | 25 |

| Tooth Angle 2β [°] | 50 |

| Rotational Speed | 20000 min-1 |

| Peripheral Speed | 80 ms-1 |

| Ultimate Tensile Strength | 1600 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength M | 400 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength V | 200 |

| [N/10mm belt width] | |

| Power Transmission | <= 5 kW |

| Specific Belt Stiffness Steel Reinforced | 1.00 x 10^5 N |

| [Per unit width/length] | |

| Unit Mass kg/m [Width: 10mm] | 0.022 |

Standard Widths [mm]:

6, 8, 12, 16, 20, 25, 32, 50, 75, 100 mm

Standard Lengths [mm]:

150, 201, 252, 267, 270, 300, 351, 399, 417, 450, 501, 549, 600, 639, 816, 900, 1011 mm

AT3 polyurethane synchronous belts Truly Endless –YONGHAG usually consist of polyurethane body and steel cord, while custom materials available upon request. Special cords include aramid (kevlar), stainless steel and carbon fiber.

AT3 PU timing belts Truly Endless –YONGHAG are most commonly offered in widths of 10mm, 16mm, 20mm, 25mm, 32mm, 50mm, 75mm and 100mm, while custom sizes (lengths, widths and pitches) are available upon request.

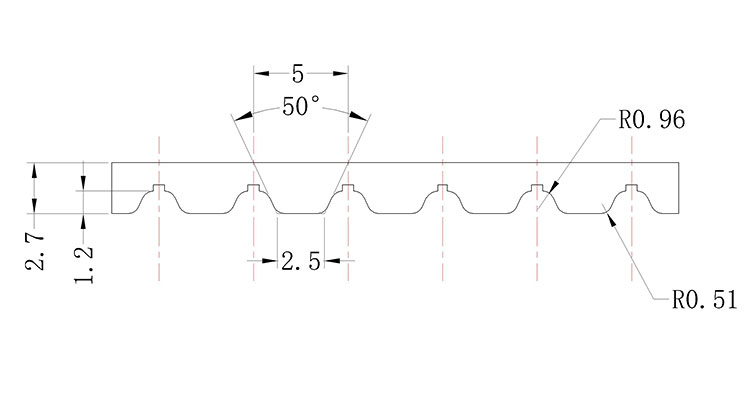

AT5 Profile Tooth figure

Description

Part No 15-AT5-500 Belt Type Truly Endless

Length [mm] 500 Pitch [mm] 5

Width [mm] 15 Number of Teeth 100

Tooth Profile AT Belt Type Closed Loop

Tensile Cord Steel Operating Temp C -30 Degrees ~ +90 Degrees C

Body Material PU Operating Temp F -22 Degrees ~ +194 Degrees F

Nylon Fabric PAZ, PAR Cleats On Request

(Note: Custom widths and sizes available upon request)

| Specifications | |

| Trapezoidal Profile | AT5 |

| Tooth Pitch t [mm] | 5 |

| Base Belt Thickness H [mm] | 1.5 |

| Tooth Height h [mm] | 1.2 |

| Overall Belt Thickness H [mm] | 2.7 |

| Width Tolerance [mm] | +/- 0.5 |

| Length Tolerance [mm] | +/- 0.5 |

| Thickness Tolerance [mm] | +/- 0.2 |

| Hardness | 92 Shore A |

| Body Materials | Polyurethane (PU) |

| Tensile Members | Steel |

| Color | White,Yellow, Black, Gray |

| Minimum of Teeth on Pulley | 15 |

| Minimum Pulley Diameter [mm] | 30 |

| Tooth Angle 2β [°] | 50 |

| Rotational Speed | 10000 min-1 |

| Peripheral Speed | 80 ms-1 |

| Ultimate Tensile Strength | 2800 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength M | 700 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength V | 318 |

| [N/10mm belt width] | |

| Power Transmission | <= 15 kW |

| Specific Belt Stiffness Steel Reinforced | 1.75 x 10^5 N |

| [Per unit width/length] | |

| Unit Mass kg/m [Width: 10mm] | 0.033 |

Standard Widths [mm]:

6, 8, 12, 16, 20, 25, 32, 50, 75, 100 mm

Standard Lengths [mm]:

225, 255, 260, 280, 300, 305, 330, 340, 375, 390, 420, 450, 455, 480, 490, 500, 525, 545, 600, 610, 620, 630, 660, 670, 690, 710, 720, 750, 780, 825, 840, 855, 860, 875, 900, 920, 960, 975, 990, 1005, 1020, 1050, 1075, 1100, 1125, 1215, 1380, 1400, 1500, 1600, 1700, 1800, 1900, 2000, 2120, 2240, 2360, 2500, 2650, 2800, 3000, 3150, 3350, 3550, 3750, 4000, 4250, 4500, 4750, 5000, 5300, 5600, 6000, 6300, 6700, 7100, 7500 mm

Description

AT5 polyurethane synchronous belts Truly Endless – YONGHANG usually consist of polyurethane body and steel cord, while custom materials available upon request. Special cords include aramid (kevlar), stainless steel and carbon fiber.

AT5 PU timing belts Truly Endless – YONGHANG are most commonly offered in widths of 10mm, 16mm, 20mm, 25mm, 32mm, 50mm, 75mm, 100mm and 150mm, while custom sizes (lengths, widths and pitches) are available upon request.

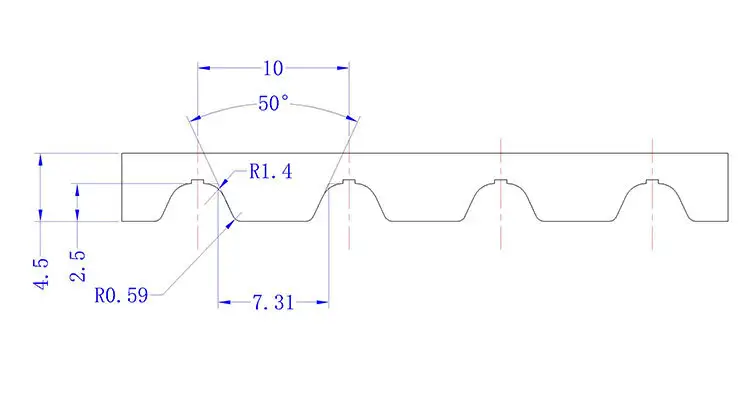

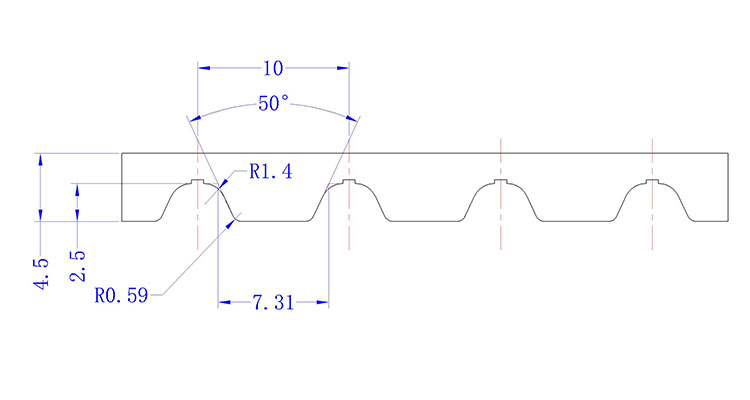

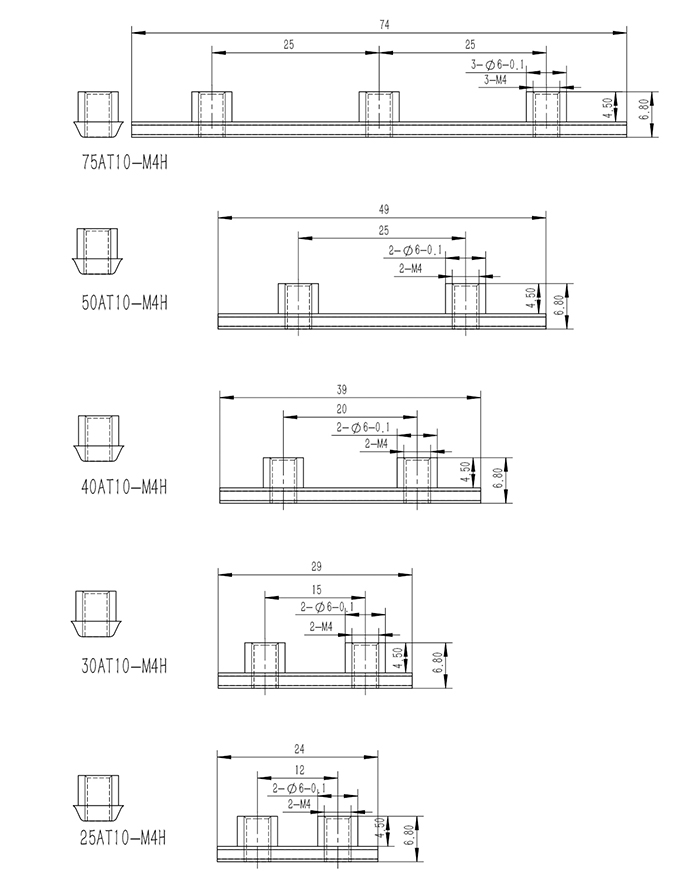

AT10 Profile Tooth figure

Description

Part No 25-AT10-2500

Length [mm] 2500 Pitch [mm] 10

Width [mm] 25 Number of Teeth 250

Tooth Profile AT Belt Type Closed Loop

Tensile Cord Steel Operating Temp C -30 Degrees ~ +90 Degrees C

Body Material PU Operating Temp F -22 Degrees ~ +194 Degrees F

Nylon Fabric PAZ, PAR Cleats On Request

(Note: Custom widths and sizes available upon request)

| Specifications | |

| Trapezoidal Profile | AT10 |

| Tooth Pitch t [mm] | 10 |

| Base Belt Thickness H [mm] | 2 |

| Tooth Height h [mm] | 2.5 |

| Overall Belt Thickness H [mm] | 4.5 |

| Width Tolerance [mm] | +/- 0.5 |

| Length Tolerance [mm] | +/- 0.5 |

| Thickness Tolerance [mm] | +/- 0.2 |

| Hardness | 92 Shore A |

| Body Materials | Polyurethane (PU) |

| Tensile Members | Steel |

| Color | White |

| Minimum of Teeth on Pulley | 15 |

| Minimum Pulley Diameter [mm] | 50 |

| Tooth Angle 2β [°] | 50 |

| Rotational Speed | 10000 min-1 |

| Peripheral Speed | 60 ms-1 |

| Ultimate Tensile Strength | 6800 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength M | 1700 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength V | 850 |

| [N/10mm belt width] | |

| Power Transmission | <= 70 kW |

| Specific Belt Stiffness Steel Reinforced | 4.25 x 10^5 N |

| [Per unit width/length] | |

| Unit Mass kg/m [Width: 10mm] | 0.058 |

Standard Widths [mm]:

10, 12, 16, 20, 25, 32, 50, 75, 100, 150 mm

Standard Lengths [mm]:

400, 440, 500, 530, 560, 580, 600, 610, 630, 66, 700, 720, 780, 800, 810, 840, 850, 880, 890, 920, 960, 970, 980, 1000, 1010, 1050, 1080, 1100, 1150, 1200, 1210, 1240, 1250, 1280, 1300, 1320, 1350, 1360, 1400, 1420, 1480, 1500, 1530, 1600, 1700, 1720, 1800, 1860, 1900, 1940, 2000, 2120, 2240, 2360, 2500, 2650, 2800, 3000, 3150, 3350, 3550, 3750, 4000, 4250, 4500, 4750, 5000, 5300, 5600, 6000, 6300, 6700, 7100, 7500, 8000, 9000 mm

Description

AT10 polyurethane synchronous belts Truly Endless – usually consist of polyurethane body and steel cord, while custom materials available upon request. Special cords include aramid (kevlar), stainless steel and carbon fiber.

AT10 PU timing belts Truly Endless – most commonly offered in widths of 10mm, 16mm, 20mm, 25mm, 32mm, 50mm, 75mm, 100mm and 150mm, while custom sizes (lengths, widths and pitches) are available upon request.

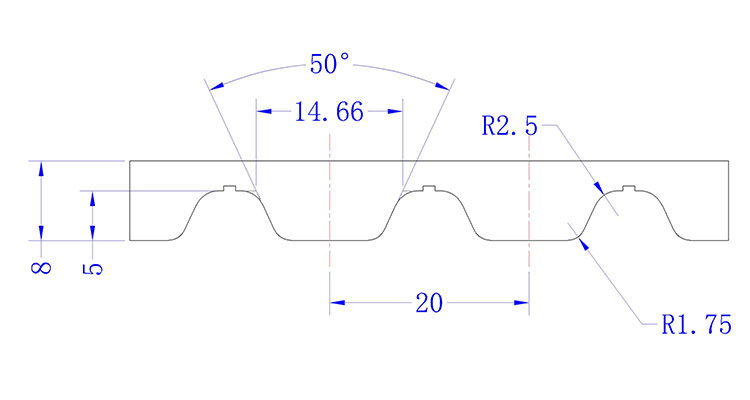

AT20 Profile Tooth figure

Description

Part No 50-AT20-5000

Length [mm] 5000 Pitch [mm] 20

Width [mm] 50 Number of Teeth 250

Tensile Cord Steel Operating Temp C -30 Degrees ~ +90 Degrees C

Body Material PU Operating Temp F -22 Degrees ~ +194 Degrees F

Nylon Fabric PAZ, PAR Cleats On Request

(Note: Custom widths and sizes available upon request)

| Specifications | |

| Trapezoidal Profile | AT20 |

| Tooth Pitch t [mm] | 20 |

| Base Belt Thickness H [mm]3 | 3 |

| Tooth Height h [mm] | 5 |

| Overall Belt Thickness H [mm] | 8 |

| Width Tolerance [mm] | +/- 1 |

| Length Tolerance [mm] | +/- 0.5 |

| Thickness Tolerance [mm] | +/- 0.4 |

| Hardness | 92 Shore A |

| Body Materials | Polyurethane (PU) |

| Tensile Members | Steel |

| Color | White,Yellow, Black, Gray |

| Minimum of Teeth on Pulley | 18 |

| Minimum Pulley Diameter [mm] | 120 |

| Tooth Angle 2β [°] | 50 |

| Rotational Speed | 6500min-1 |

| Peripheral Speed | 40ms-1 |

| Ultimate Tensile Strength | 8960 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength M | 2240 |

| [N/10mm belt width] | |

| Maximum Allowable Tensile Strength V | 1066 |

| [N/10mm belt width] | |

| Power Transmission | >= 200 kW |

| Specific Belt Stiffness Steel Reinforced | 5.60 x 10^5 N |

| [Per unit width/length] | |

| Unit Mass kg/m [Width: 10mm] | 0.096 |

Standard Widths [mm]:

25, 32, 50, 75, 100, 150 mm

Standard Lengths [mm]:

1000, 1100, 1200, 1260, 1500, 1600, 1700, 1760, 1800, 1900, 1960, 2000, 2120, 2240, 2360, 2500, 2660, 2800, 3000, 3160, 3360, 3560, 3760, 4000, 4260, 4500, 4760, 5000, 5300, 5600, 6000, 6300, 6700, 7100, 7500, 8000, 8500, 9000 mm

AT20 polyurethane synchronous belts Truly Endless – YONGHANG usually consist of polyurethane body and steel cord, while custom materials available upon request. Special cords include aramid (kevlar), stainless steel and carbon fiber.

AT20 PU timing belts Truly Endless – YONGHANG are most commonly offered in widths of 10mm, 16mm, 20mm, 25mm, 32mm, 50mm, 75mm, 100mm and 150mm, while custom sizes (lengths, widths and pitches) are available upon request.

Belts joint

Truly Seamless (moulded)

Endless with joint

Open Ended

Tensile Cords

Steel Cords

Reinforced Steel Cords

Stainless Steel Cords

Aramid Kevlar Cords

Extra Flexible Steel Cords

Reducing Sliding Resistance

Nylon Fabric on Tooth Side (PAZ / NFT)

Nylon Fabric on Back Side (PAR / NFB)

Nylon Fabric on Tooth Side & Back Side (PAZ/PAR)

Mechanical properties

Friction / adhesion

Abrasion resistance

Wear resistance

Release

Cut resistance

Compressibility

Physical properties

Antistatic

Electrical conductivity

Flame retardant

Cold resistance

Hydrolysis resistance

Chemical properties

Oil and fat resistance

Food approved

Easy to clean

Acid and base resistance

Ozone and UV resistance

Applications

apply to construction machines, pumps, paper-making machines, compressors, textile machines, roller-table drives

FAQ

What are differences between T and AT series timing belt?

Tooth Shape Design: T series is standard trapezoidal tooth shape, while AT is enhanced trapezoidal tooth shape with deeper tooth root.

Load Capacity: T series synchronous belt is suitable for low or medium load, while AT is ideal for high load and high torque transmission.

Transmission Accuracy: Compared with T series toothed belt, AT has higher accuracy and favorable for more complex application situation.

Does AT timing belt support reverse bending?

AT timing belts can withstand reverse bending to some extent, but frequent reverse bending may accelerate aging and wear. For applications requiring frequent reverse bending, specially designed timing belts are recommended

Can we get belt sample before we place order?

Yes, of course, timing belt sample is available. Before placing formal order, we can send you small timing belt sample for you to check belt teeth model and material.

How can AT timing belt avoid tooth skipping?

Ensure Alignment Accuracy: Ensure alignment accuracy of belt pulley and timing belt to avoid mismatch between belt teeth and pulley teeth.

Appropriate Tension: Keep the tension of the timing belt within the appropriate range to avoid too tight or too lose.

Avoid Overload: Do not expose the toothed belt to operating conditions exceeding its rated load.

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details