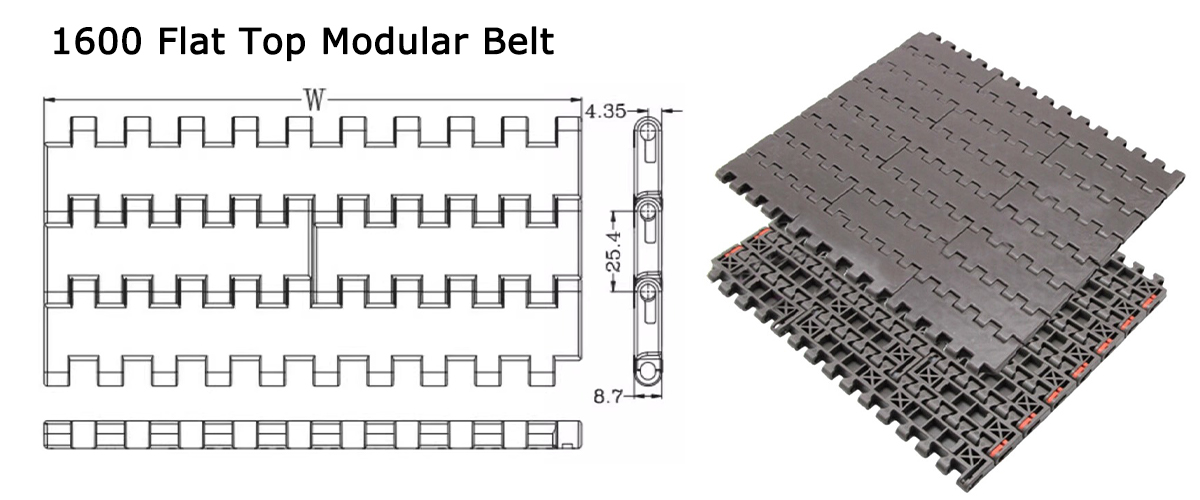

1600 Flat Top Plastic Modular Conveyor Belt

1600 Flat Top Plastic Modular Conveyor Belt are constructed with modules molded from thermoplastic materials connected with solid plastic rods. Except for narrow belts (one complete module or less in width), all are built with the joints between modules staggered with those of adjacent rows in a "bricklayed" fashion. This structure can enhance transverse strength and it is easy for maintain.

The total plastic and cleanable design can sove the steel belts easily polluted. Now the cleanable design makes the belts very suitable for food industry area as well. Also there are be widely used in many other industries, such as container making, pharmaceutical and automotive, lines of battery and so on.

Belt Pitch: 25.4mm

Belt Material: POM/PP/PE

Backflex radius: 25mm

Assembling Method:Connected with rods

Color: Blue, Brown, Gray, White

Minimum indent is 25.4mm

The material is selected based on the application field.Width can be customized according to requirements.

| 1600 flat top modular plastic conveyor belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius (min) | Work Temperature | Monolithic width | assemble |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| 1600 flat top modular plastic conveyor belt | 25.4 | POM | PP | 4.6 | 20000 | 7.6 | 8.7 | 25 | -30℃~+80℃ | 85/170 | W=85*N |

| 25.4 | PA | 4.6 | 22000 | 7.7 | 8.7 | 25 | -30℃~+90℃ | 85/170 | |||

| 25.4 | PP | PP | 4.6 | 12000 | 4.9 | 8.7 | 25 | +4℃~+104℃ | 85/170 | ||

| 25.4 | PE | PE | 4.6 | 5000 | 5.37 | 8.7 | 25 | -40℃~+65℃ | 85/170 | ||

| Open Area 0% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

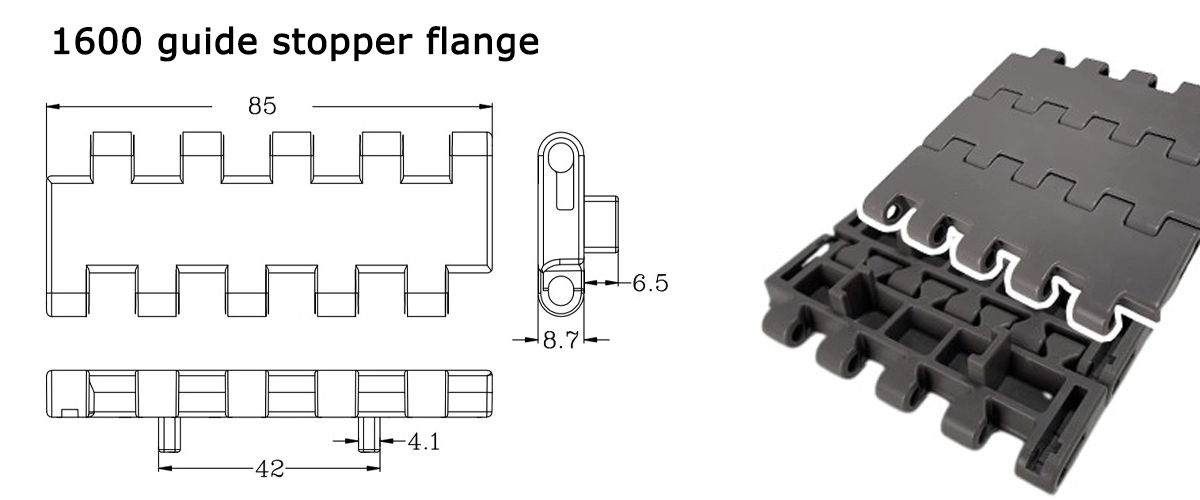

1600 Guide positioning module flat top chain plate,Fixed width is 85mm.If you need any other width, please contact us.

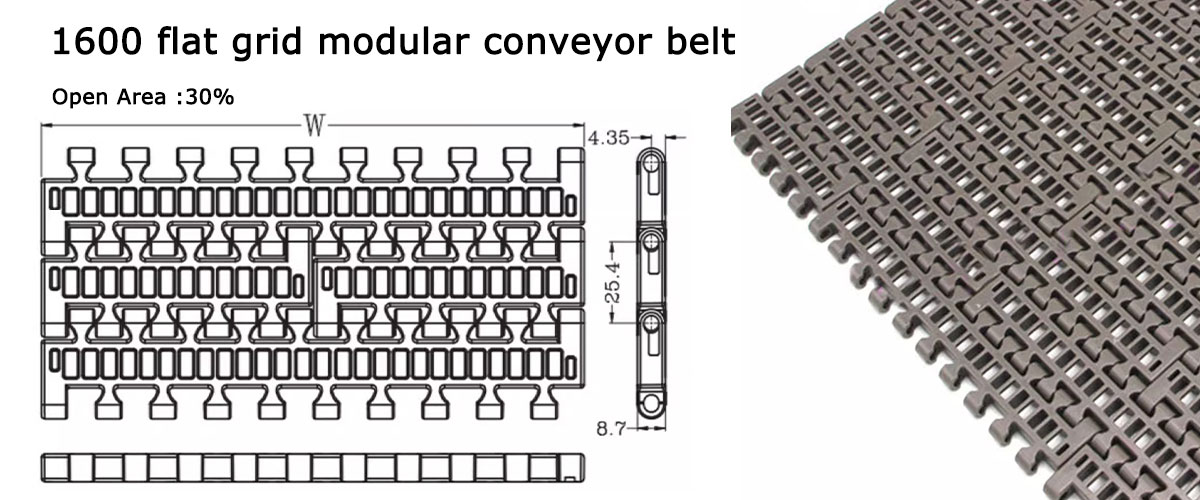

| 1600 flat grid modular conveyorbelt data table | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | working load(max) | weight | thickness | back flex radius (min) | work temperature | monolithic width | assemble width |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| 1600 flat grid belt | 25.4 | POM | PP | 4.6 | 21600 | 5.5 | 8.7 | 25 | -30℃~+80℃ | 85/170 | Due to the positioning limitations of the sprocket, it is recommended not to use non-standard width. |

| 25.4 | PA | 4.6 | 21600 | 5.6 | 8.7 | 25 | -30℃~+90℃ | 85/170 | |||

| 25.4 | PP | PP | 4.6 | 1200 | 3.6 | 8.7 | 25 | +4℃~+104℃ | 85/170 | ||

| Open Area 30% (due to different material shrinkage,Actual will be lower than standard width 1%-3%) | |||||||||||

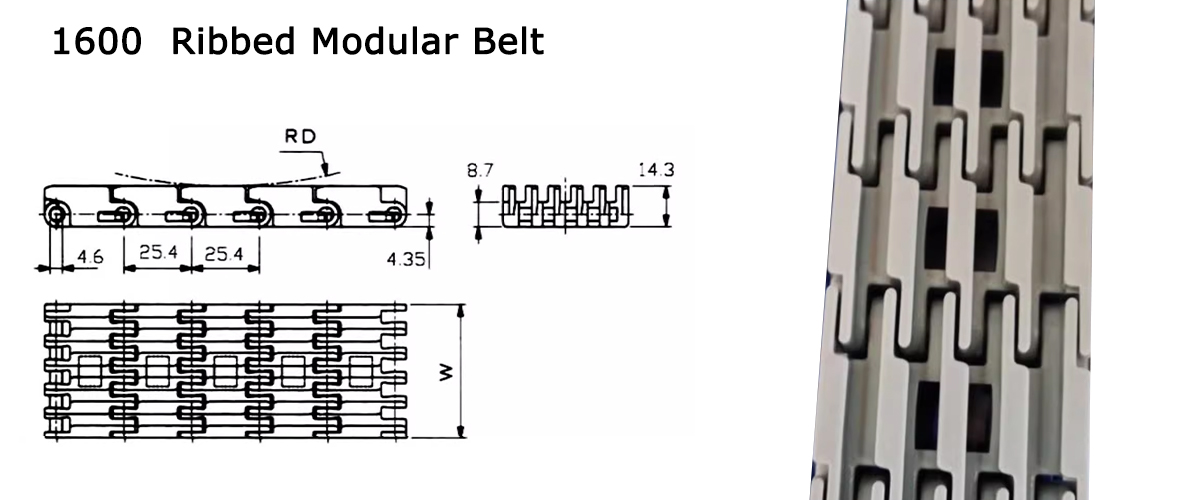

| 1600 raised rib modular belt data table | ||||||||||

| Belt type | Pitch | Belt width | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius (min) | Work Temperature |

| mm | mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | |||

| 1600 raised rib modular belt | 25.4 | 30 | POM | PP | 4.6 | 700 | 0.39 | 14.3 | 240 | -30℃~+80℃ |

| 25.4 | 38.5 | 4.6 | 950 | 0.5 | 14.3 | 240 | ||||

| 25.4 | 47 | 4.6 | 1150 | 0.6 | 14.3 | 240 | ||||

| 25.4 | 58 | 4.6 | 1400 | 0.75 | 14.3 | 240 | ||||

| 25.4 | 30 | PP | PP | 4.6 | 315 | 0.27 | 14.3 | 240 | +4℃~+104℃ | |

| 25.4 | 38.5 | 4.6 | 415 | 0.33 | 14.3 | 240 | ||||

| 25.4 | 47 | 4.6 | 500 | 0.4 | 14.3 | 240 | ||||

| 25.4 | 58 | 4.6 | 650 | 0.49 | 14.3 | 240 | ||||

| Open Area 46% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | ||||||||||

| Machine | Teeth | Pitch Diametet(mm) | Outside Diameter | Bore Size | ||

| Sprockets | mm | Inch | mm | Inch | mm | |

| 1600-14T | 14 | 114.15 | 4.49 | 114.4 | 4.5 | 20 25 30 |

| 1600-16T | 16 | 130.2 | 5.12 | 130.3 | 5.13 | 20 25 30 35 40 |

| 1600-18T | 18 | 146.3 | 5.76 | 146.5 | 5.77 | 20 25 30 35 40 |

| 1600-19T | 19 | 154.3 | 6.07 | 154.6 | 6.08 | 20 25 30 35 40 |

| 1600-20T | 20 | 162.4 | 6.39 | 162.8 | 6.4 | 20 25 30 35 40 |

| Special tooth counts can be customized. The shaft bore diameter can be square or round. The injection molded Sprockets material can be POM, PP, or PA. The machined material can be PA/PP. | ||||||

Application:

Bakery, Dairy, Fruit, and Vegetable

We have extensive experience in developing specialized solutions tailored to the needs of many different Bakery industry segments: bread and bun, fresh pastry (oven and fried pastry), pizza, pasta (fresh and dry), frozen bread, frozen pastry, cookies, and crackers, with our material handling equipment conveyor systems conveyor plastic modular belt conveyor you can get surprised!

Meat Poultry Seafood

With belts and accessories designed to meet the specific needs of fruit and vegetable processing and packaging applications, Hairise is committed to helping customers achieve their operational and business goals.

Hairise continues to develop new and better ways for customers to increase throughput efficiency, improve sanitation, and reduce the costs of belt ownership.

Material handling equipment conveyor systems conveyor plastic modular belt conveyor technology to meet the specific challenges of seafood processors.

Ready Meals

Ready meal customers who equip their lines with Hairise Industrial plastic slat table top food grade conveyor chain realize many critical benefits, including:

·Reduced sanitation costs and improved food safety

·Improved line efficiency and maintain product alignment

·Reduced unscheduled downtime and reduced labor needs

Contact Details