round belt welding Connect machine High-precision aluminum alloy splicer

The outer shell of the hot melt machine is made of iron sheet, and its quality is better than that of plastic. When connecting, the temperature of the hot melt device must be within 250 degrees; otherwise, it will affect the physical properties of the polyurethane. If the connection temperature is too high, the interface of the polyurethane round belt and V-belt is prone to breakage when used. Our store's hot melt device can adjust the temperature. Ordinary soldering irons cannot adjust the temperature. When the temperature exceeds 500 degrees, the interface of the belt is prone to breakage during use. The scissors handle is randomly dispatched in two colors: red and black

round belt welding machine in China,hot melt machine,High-precision aluminum alloy splicer and round belt Special scissors,All polyurethane round belt and TPU V-belt can be welded.

Round belts welding process mainly takes place in four steps:

Preparing round belts

The belt ends are cut off by angle cut or 90° cut

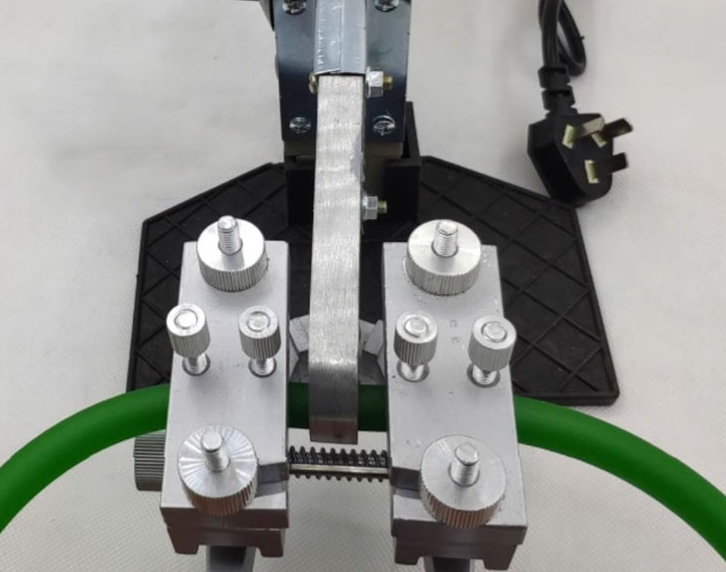

Clamping the belt in the guide unit

The guide unit or clamp ensures perfect alignment of the belt ends to be spliced.

Welding belts

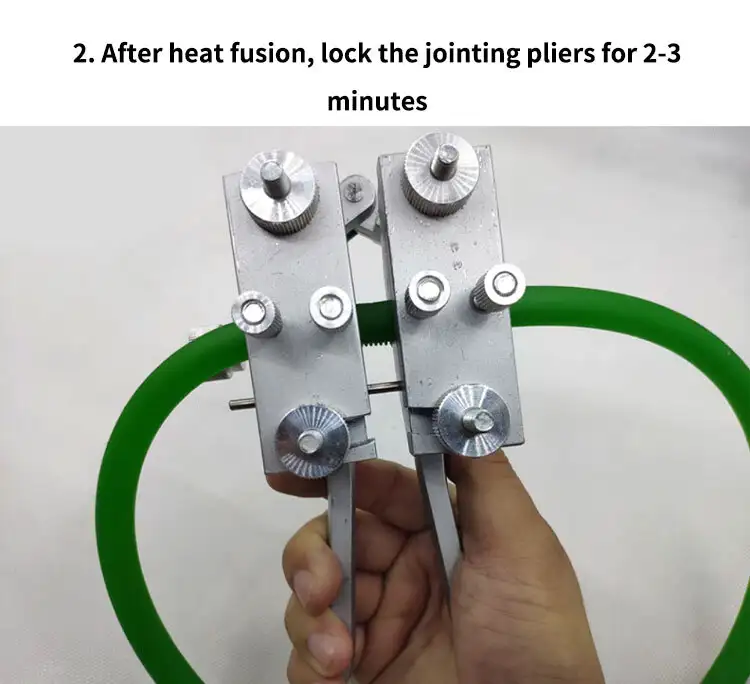

FFor PU belts 250°C are required

Clean the belt

After the welding process and the cooling time only the welding bead has to be removed with a edge cutter or sharp knife.

Contact Details