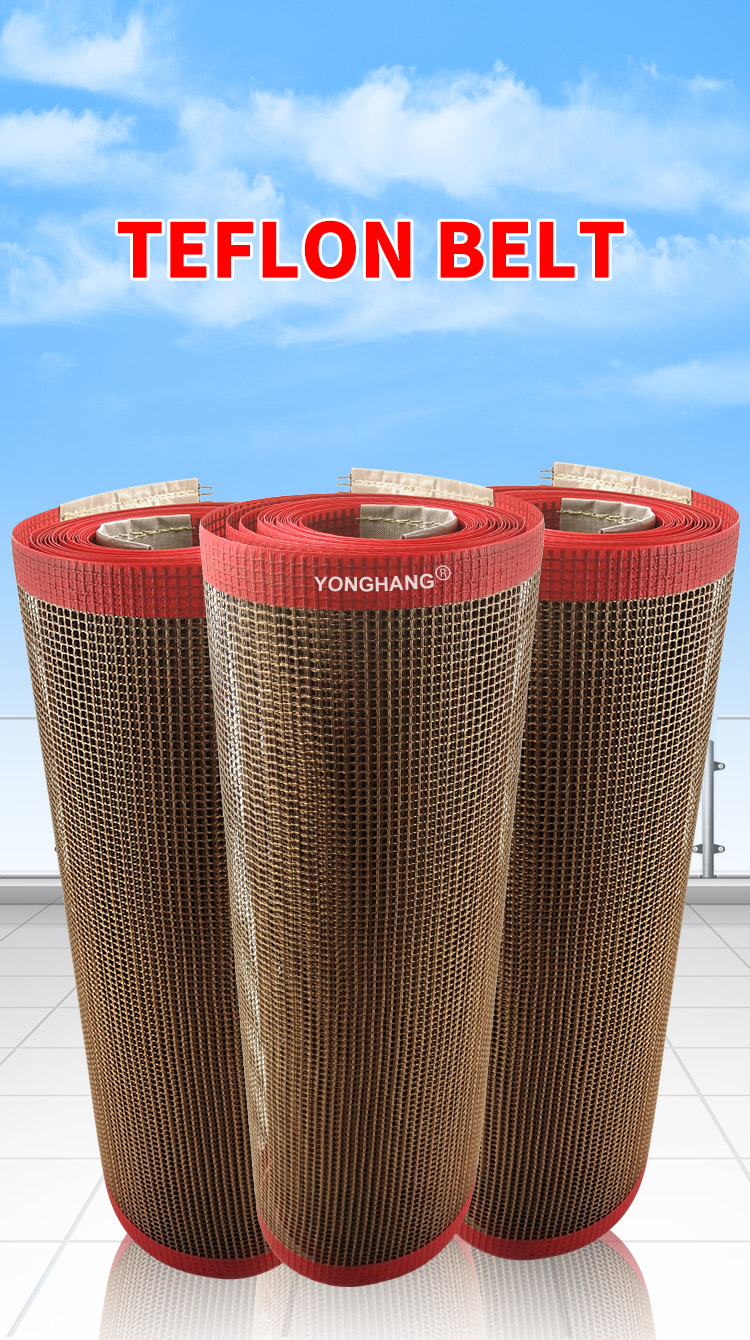

Heat transfer food grade ptfe teflon coated fiberglass mesh conveyer belt

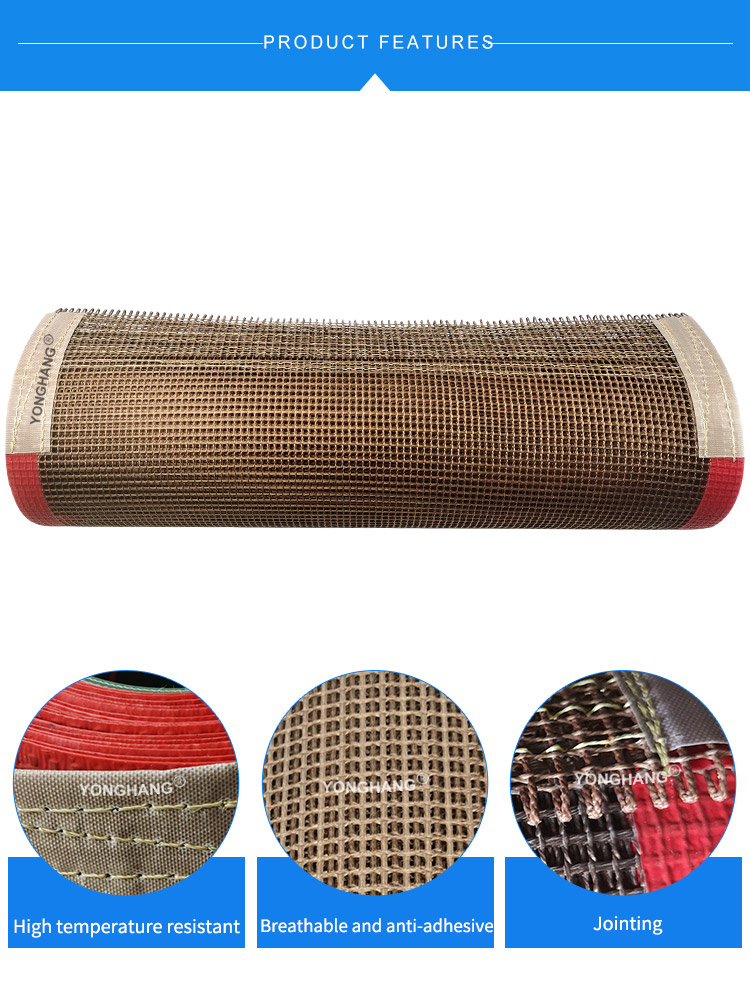

Heat transfer ptfe teflon coated fiberglass mesh conveyer belt.PTFE Conveyor Belts are specifically engineered with the mechanical strength needed for the fusing and laminating industries. Its non-stick surface, thermal transfer and high temperature resistance characteristics ensure the flow of woven and non-woven materials through the fusing and lamination process. These belts are for fusing machines, such as Oshima, Kannegiesser, Meyer, Macpi, and many others.

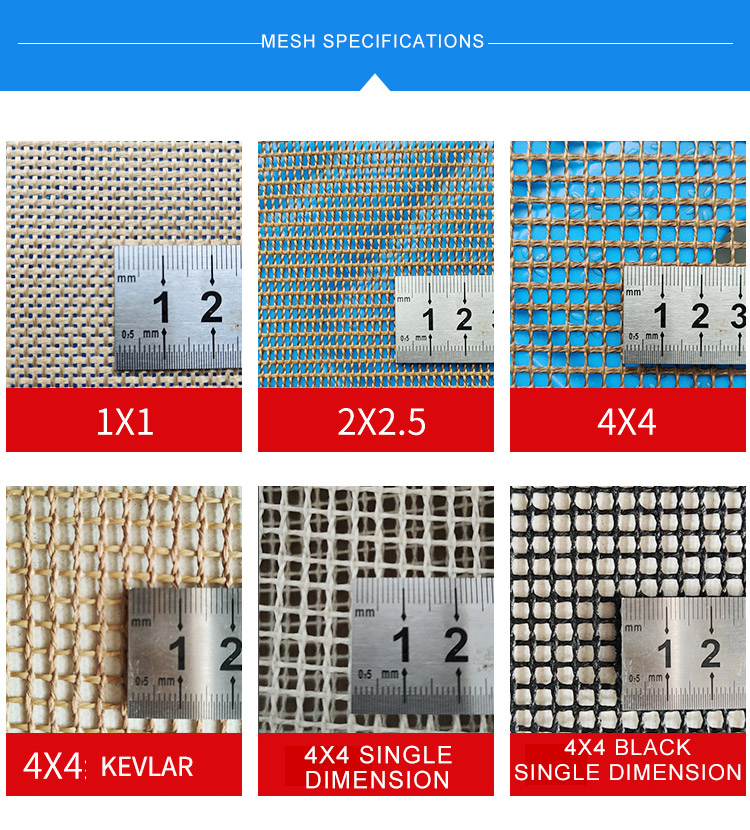

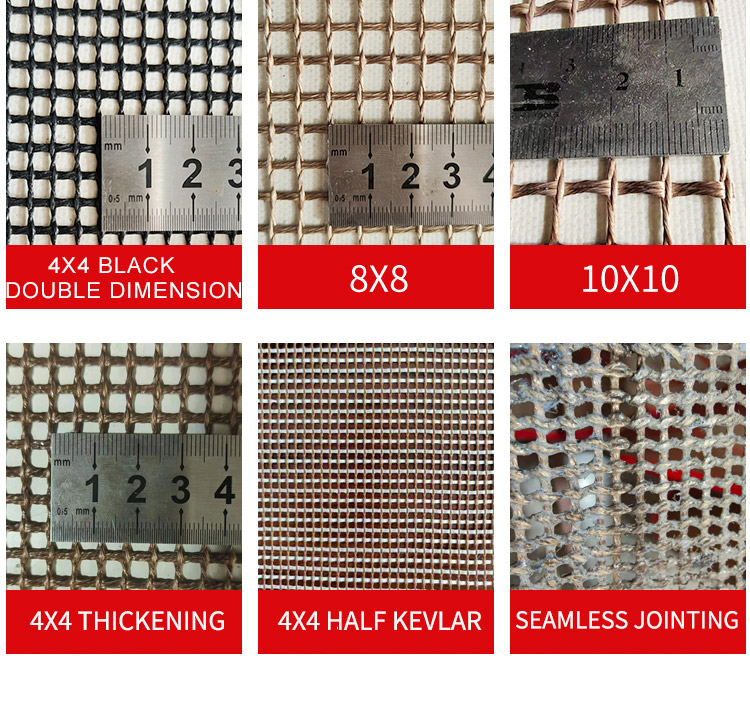

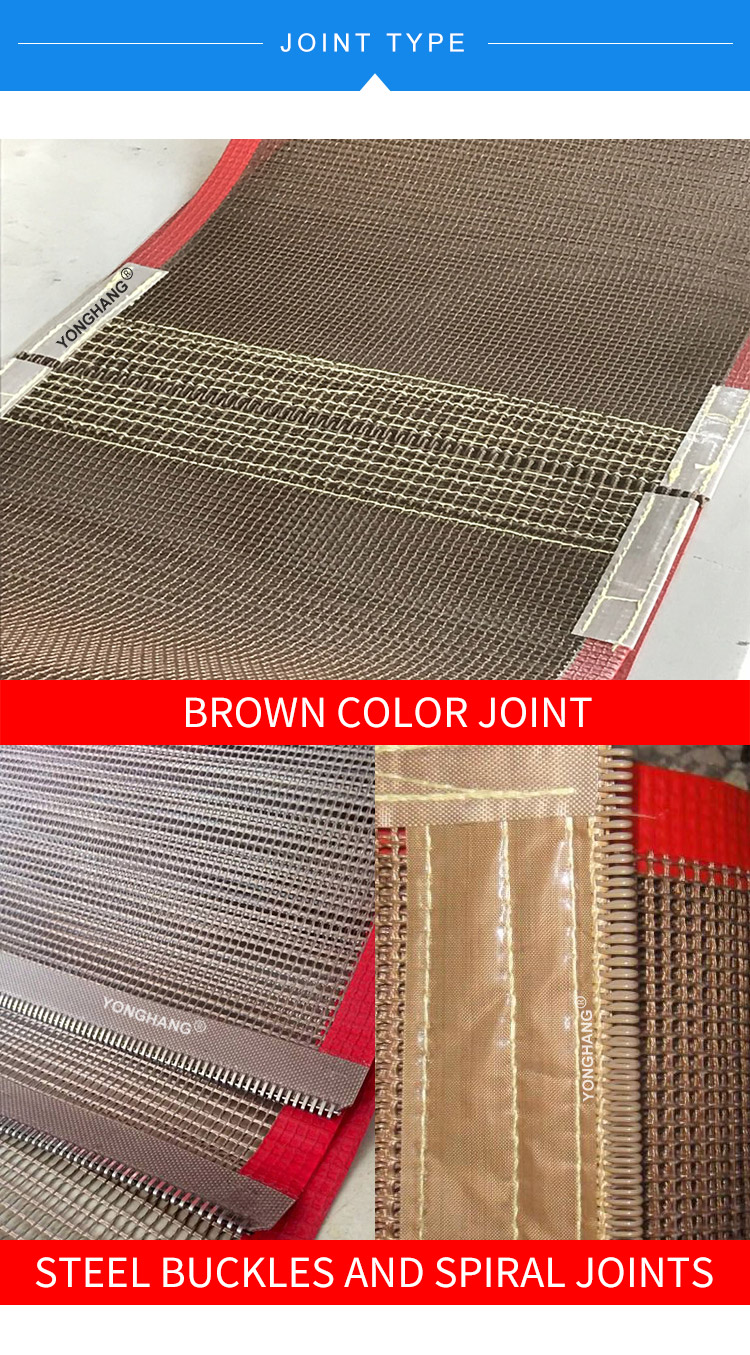

Teflon conveyor belt, also called Teflon (PTFE) conveyor belt, is divided into two types: mesh conveyor belt and high-temperature cloth conveyor belt, both are made of glass fiber as the base fabric, coated with Teflon resin to make a kind of high-temperature resistant conveyor belt, up to 260 ℃ ~ Usually the edge style is divided into: Teflon turning film edge, Kevlar edge, Teflon cloth edge, etc. The joint method is mainly soft joint (bull nose joint) and steel buckle joints. Suitable for all types of drying machinery!

Features:

Lightweight and energy efficiency for economical operation

2. Outstanding temperature resistance (-170°C + 260°C)

3. Low thermal mass

4. Controlled porosity

5. Superior non-stick surface, easy to clean

6. Exceptional strength and dimensional stability

7. Superior tracking

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

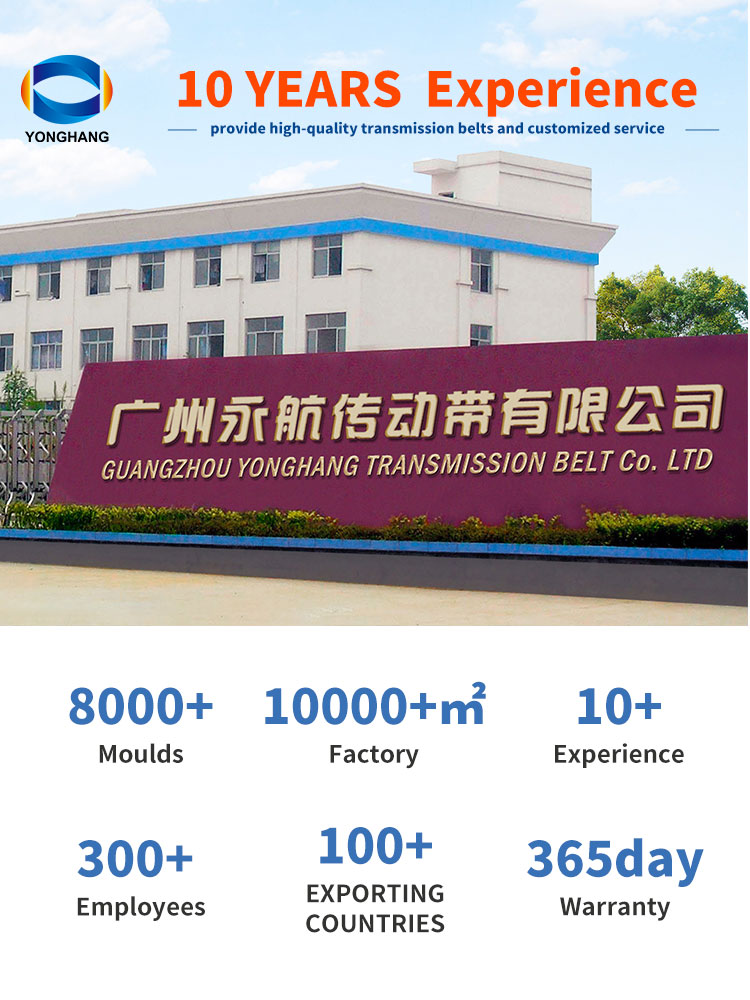

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details