12 Years Transmission Belts Coating Customized Factory.

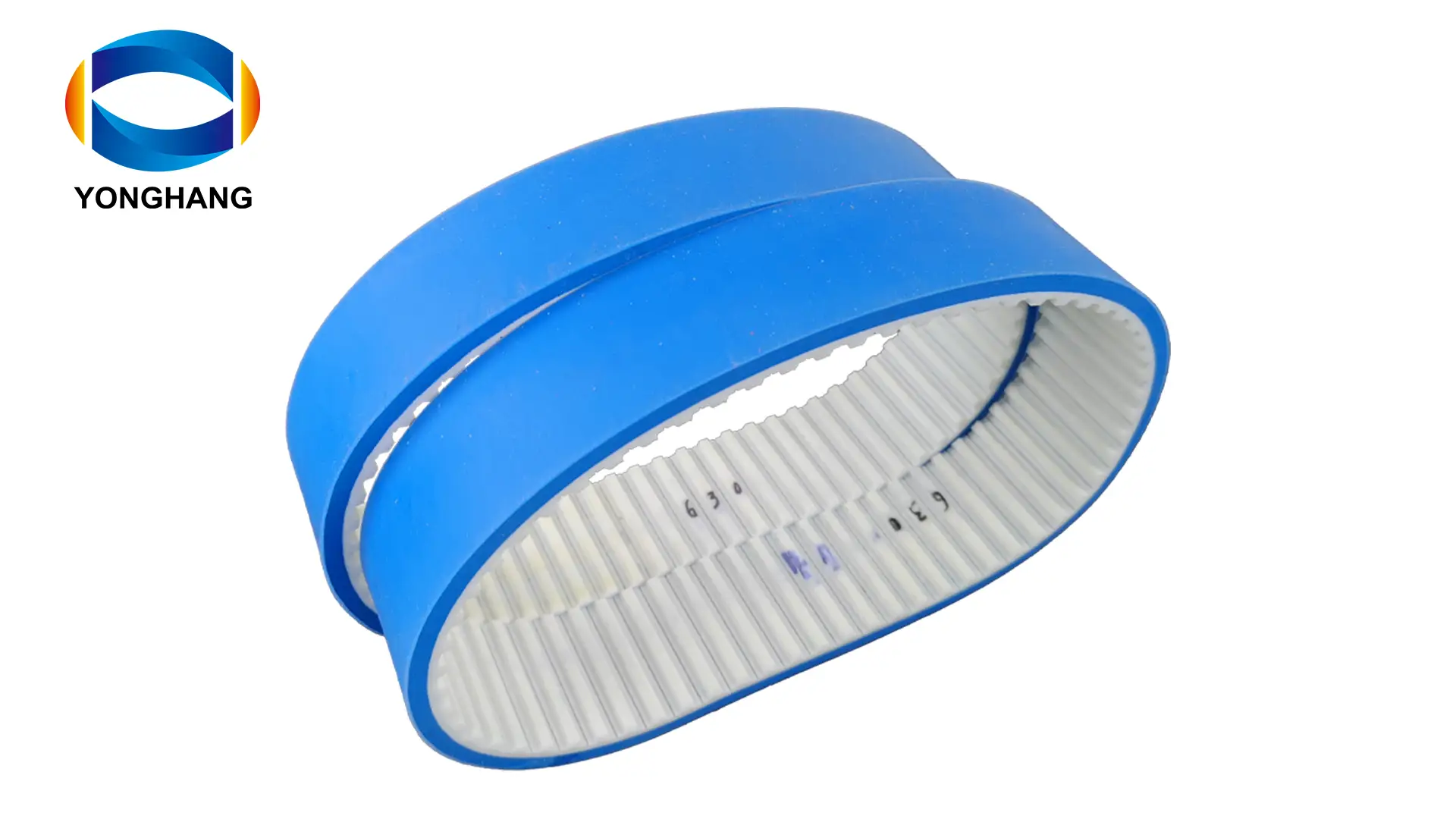

Best Yonghangbelt custom anti-adhesion heat resistant blue silicone coated pu timing belts

blue silicone coated pu timing belts

Color :Blue/white/transparent

Size:Customized

Length:Customized

Width:10-550mm

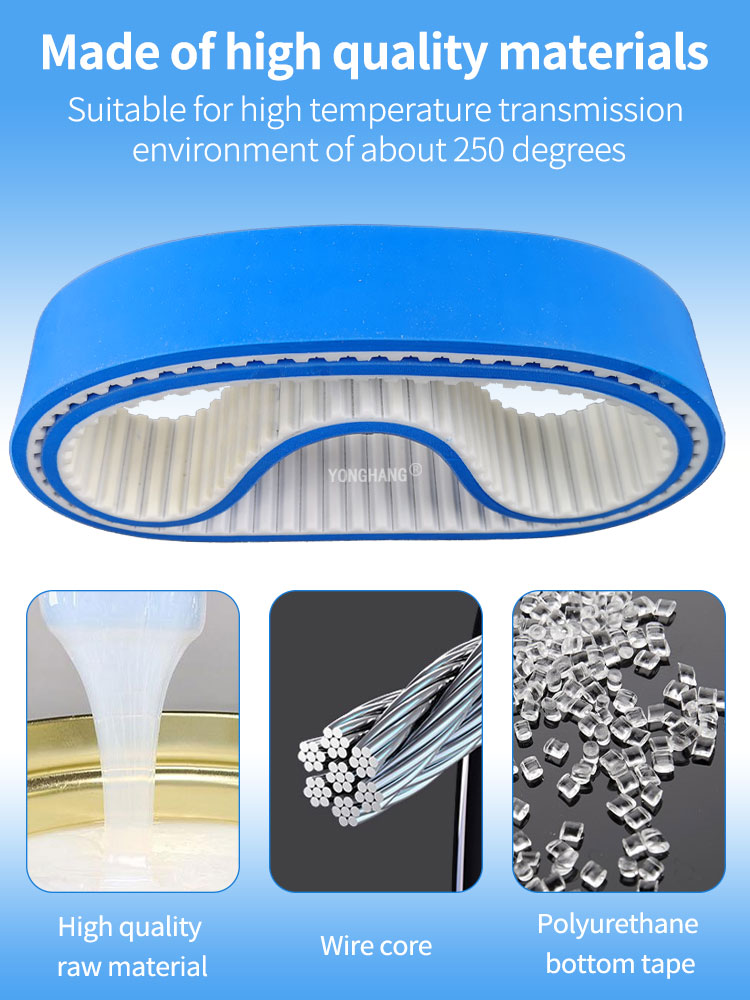

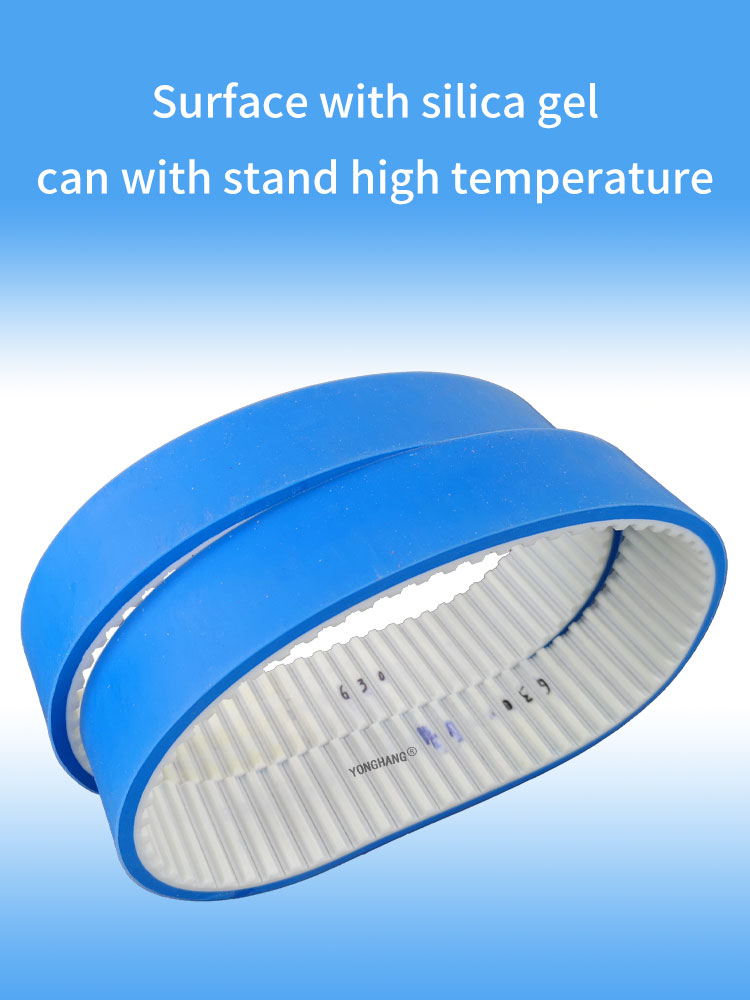

Material:PU/Silicone coated

Type:tooth type

Coated:2-15mm

Silicone Shore hardness (A):45° Shore A

Working temperature:-20-+250°C

Joint:Endless with joint/Seamless (moulded)

Cords:steel/ kevlar

Silicone coated PU timing belts have several distinctive features:

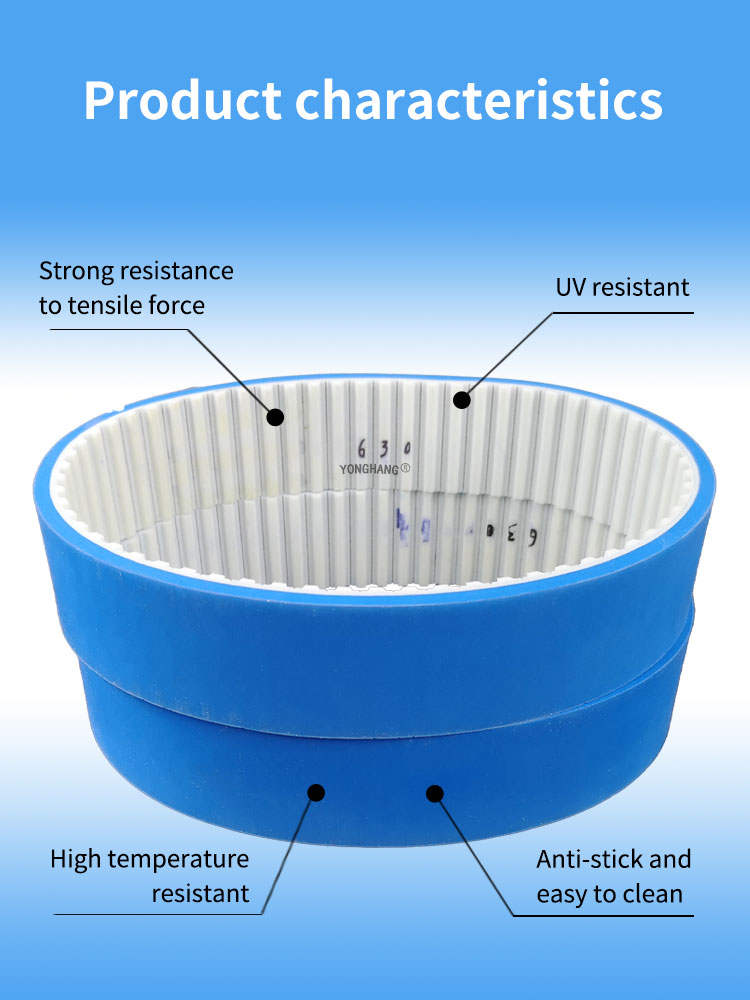

Excellent wear resistance: The silicone coating enhances the durability and longevity of the belts, making them suitable for demanding applications.

High flexibility: The PU material provides flexibility, allowing the belts to adapt to pulley systems and maintain precise synchronization.

Low maintenance: The silicone coating reduces the need for frequent lubrication, contributing to lower maintenance requirements.

Temperature resistance: The silicone coating provides thermal stability, making the belts suitable for a wide range of operating temperatures.

Reduced noise and vibration: The flexible and coated nature of these belts can contribute to smoother, quieter operation in various industrial settings.

These features make silicone coated PU flex timing belts a popular choice for applications requiring precise movement and durability.

Contact Details