People often ask why we use different joining methods for different types of polyamide power transmission belts. I will describe the various methods of joining belts. The most common joining methods we use are:

Connection methods for polyamide power transmission belts and conveyor belts

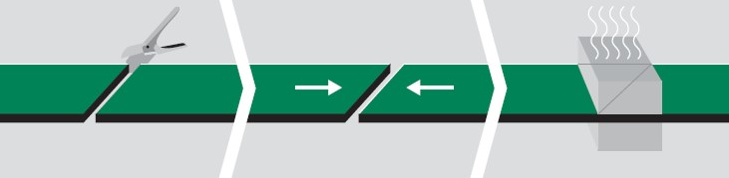

Quick fusion splice

This simple and fast fusion jointing method can be used for belts that are almost entirely made up of thermoplastic material. The end of the belt is cut at an angle to a certain length, fixed in the guide and then hot pressed to melt the material. We use this method when the pulley diameter is small and the working temperature is not higher than 80C/176°F. Quickmelt is usually used for round belts, elastic machine belts and integral belts. The quality of the joint can be easily assessed by visual inspection and the thermoplastic material can be repeatedly fused.

Quick fusion splice

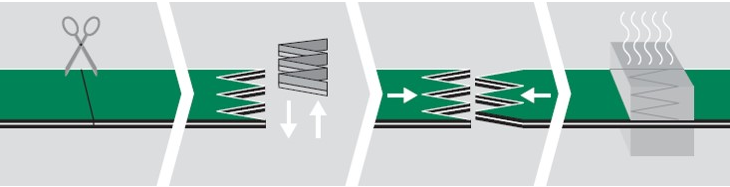

Anti-bend fusion joints

If there are fusible layers and fabrics in the belt construction, including at least one layer of thermoplastic material, we can use finger joints to achieve this easy and fast fusion method. The belt ends are cut in a finger shape, matched together and then hot pressed. For this type of joint, the weld length determines the tensile strength.

For polyamide power transmission belts with a polyester traction layer, we use long, thin fingers

Standard conveyor belts use medium fingers

Short fingers for machine tapes

If the joining procedure is completed correctly, the bend-proof joints provide more than 70% of the original belt tensile force at room temperature. The high flexibility on the joint allows for the smallest minimum pulley diameters. The fusion joint can be used at operating temperatures of up to 80°C / 176°F. Higher operating temperatures may be possible, however, the joint will deteriorate more quickly at these higher temperatures than other belts due to its variable thermal history. The quality of the joint can easily be assessed by visual inspection and the thermoplastic material can be repeatedly melted.

Anti-bend fusion joints

Stepflex fusion joints

This jointing method is mainly used for PVC belts which have guides on the running side of the belt or for use in contaminated environments. The belt is divided into a lower and an upper part and is finger-punched on both parts which are staggered in the longitudinal direction. The keys are fused together by means of a fusible intermediate layer.

Thanks to this overlapping/staggered joining technique, the fingers are more resilient to local pressure below/above the belt and therefore the weld has a higher resistance to penetration.

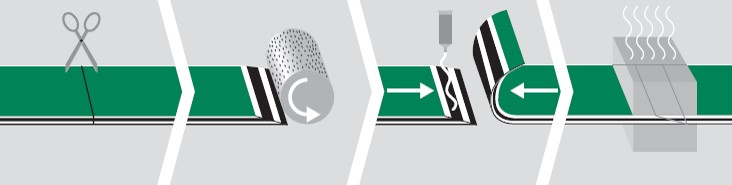

Thermoset bonded joints

Thermofix is a bonding joint method for conveyor belts and power transmission belts that require a combination of different materials of non-thermoplastic plastics (e.g. rubber or silicone and polyamide) with high resilience and/or impact resistance. It is suitable for operating temperatures of up to 100°C/212°F, but is not suitable for small pulley diameters. If nylon (polyamide) layers are present, they are combined into a single unit using a chemical bonding method.

The ends of the belt are cut into wedges, with one end of the belt starting at the top and the other end at the bottom side, which are then bonded together using a bonding system, heated and pressurised. This is a very strong welding method and, provided the joining process is completed correctly, the Thermofix method provides more than 70% of the original belt tensile force at room temperature. Careful workmanship is required as different adhesives and welding times are used, which is time consuming. After the heating procedure the joint is not reversible and the quality of the joint cannot be assessed visually. The joint has good resistance to lateral forces and dust on the pulley.

Thermoset bonded joints

Mechanical fasteners

Mechanical fasteners mechanically connect or fix two objects together. They are used where belts must be changed regularly or in applications where a quick change of belt is required. However, mechanical fasteners are a wearable part of the belt and can have openings into areas where dirt can enter, making this not the preferred solution for many applications.

Which belt uses which connection method?

For further support, please contact us for individual support.

Please contact us direct for more information regarding your specific requirements.

URL video:http://www.yhbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :sales@yhbelt.com

Contact Details