rubber synchronous drive belt with coated for pipe bending machine

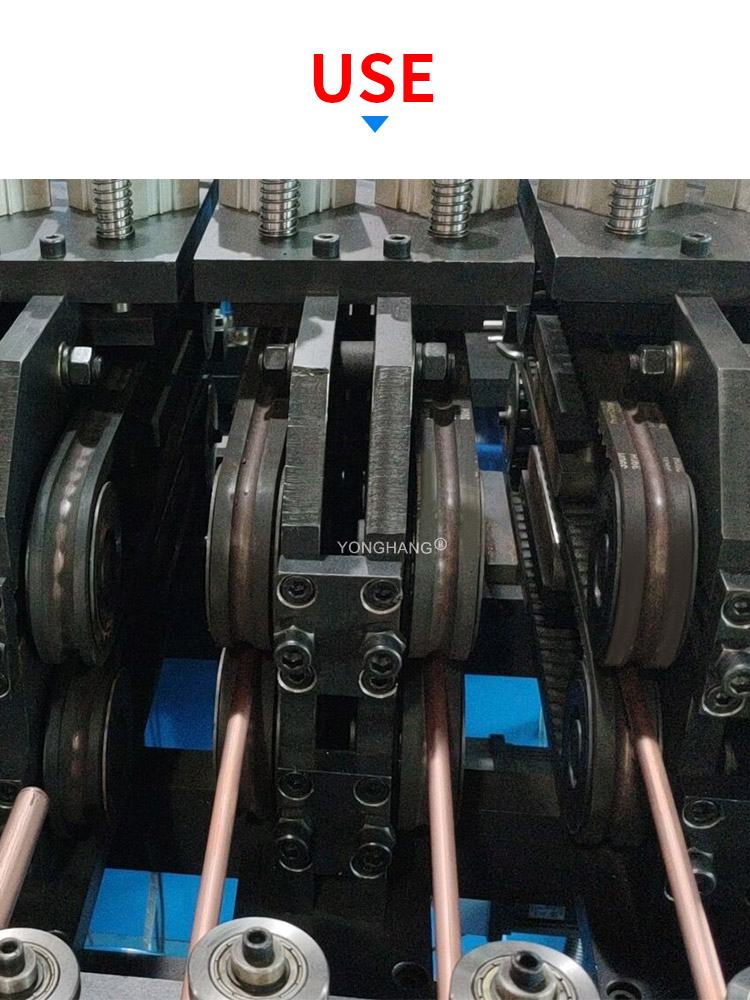

rubber synchronous drive belt with coated for pipe bending machine,This coated timings belt is grooved according to the size of the pipes on the production line. The groove dimensions are precisely matched to the size of the wire pipe, thus achieving precise traction.

Regarding the common tooth shapes and specifications of the belt for the bending machine, we hope this will help you gain a deeper understanding of our product!

Color :Black ,White ,Red ,green,brown,grey,Blue etc

Size (length * width * height): 400mm-1500mm*20-35mm*4-12mm(SIZE 0F SINK HOLE is Customizable)

Material:Vulcanized rubber

Tooth shape: Circular arc tooth,Trapezoidal tooth

Whether standard parts: Standard

Process (construction): Vulcanized rubber belt punching ,Single row hole, multi - emptying evenly distributed

Performance: Excellent strong friction wear resistance, oil and corrosion resistance, no lamination, long service life

Processing: punch/ slot / pattern / block / guide bar / profile

Use (for machines):Used for pulling plastic film in packaging machine, Printing industry, packaging industry, paste box machine belt,

vertical packaging machine, food and medicine packaging industry

Pipe Bending machine belts are true seamless integrated vulcanization molding,With high wear resistance and tensile strength, enable simultaneous bending of multiple tubes, significantly boosting bending efficiency and earning widespread user preference.

The most common tooth profiles for pipe bending machine belts on the market are trapezoidal teeth (imperial teeth) including H-profile, T10-profile, AT10-profile, and 8M arc teeth. Belts are typically slotted on the surface according to the size of copper tubes used by customers, generally with R6 or R5 slots. Slot widths primarily include 2mm, 2.5mm, 4mm, 5mm, 6mm, 7mm, 7.94mm, 8mm, 9.52mm, and 12.7mm. To reduce customer costs, these belts can be slit into individual slots for use. Should one slot become damaged during operation, only that section needs replacement, significantly lowering maintenance expenses!

Advantage

Yonghang pipe bending machine belts feature excellent dynamic flexibility, superior crack resistance, low elongation, extended service life, and outstanding wear resistance! With a comprehensive range of molds

we offer customization for various specifications, including surface rubber coating color and thickness. Quality is guaranteed with a 12-month warranty and technical support—purchase with confidence! Factory direct sales provide lower prices for bulk orders. For inquiries, please consult online or call us.

coated Color :Black ,White ,Red ,green,brown,grey,Blue etc

Material:Vulcanized rubber

Tooth shape: Trapezoidal tooth

commonly used size:330H100 340H100 560H 530H 650H100 680H100 750H100 8M-1000-25 8M-1040-25

Standard Width:1 inch/25mm/30mm/35mm/50mm

coated thickness:2mm-15mm

Application:Suitable for cold bending of welded pipes for low-pressure fluid conveyance, electric welded steel pipes, general-purpose steel pipes, and bending of pipes of specifications other than the same type, as well as non-ferrous metal pipes.

Five Key Reasons to Choose Yonghang Pipe Bending Machine Belts

1. Consistent Quality: Manufactured using mature molded vulcanization technology, featuring seamless construction without joints or gaps. Ensures no longitudinal fractures or delamination during use, guaranteeing stable performance!

2. Premium Materials: Crafted from imported Thai neoprene rubber with 90% rubber content. Reinforced with high-strength glass fiber cord as the reinforcement layer, enhancing tensile strength by 35% and delivering excellent dimensional stability!

3. Superior Performance: High strength, exceptional wear resistance, and superior tensile strength ensure extended durability and longevity!

4. Customizable: Yonghang integrates R&D, production, and customization under a factory-direct model, offering one-stop service. Our 10,000-square-meter facility houses over 8,000 production molds and 50+ precision machines, supporting full-scale processing and custom specifications based on drawings or samples!

5. Quality Assurance: With 12 years of industry experience, Yonghang possesses mature technology and processes across all aspects, ensuring reliable quality. All products come with a 12-month free warranty and technical support!

For further technical inquiries, please feel free to contact us.

Contact Details