Industrial Polyester Conveyor Laundry Ironing Machines belts

Our special polyester/Meta Aramid needled felt belt has a very smooth surface, which gives a non-marking finishing to the linen, associated to higher air permeability, which increases the output of the ironer.

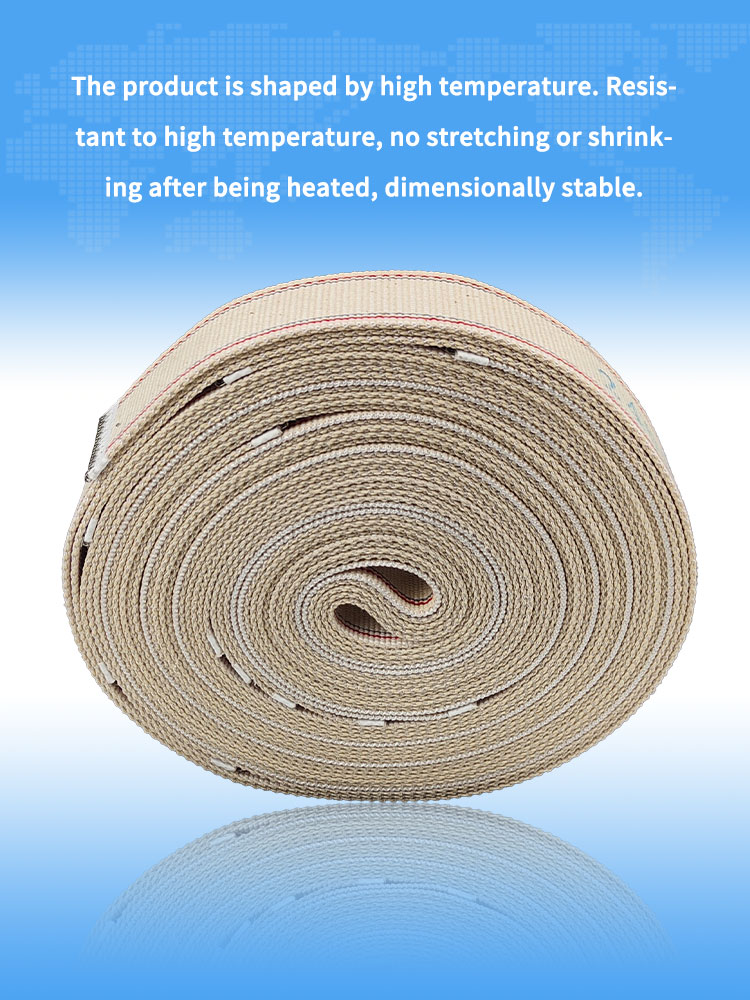

The ironing belt is composed of needled felt with a heavy-duty polyester fabric scrim and polyester fiber on one side and Meta Aramid fiber on the heated roll side for working temperature of max. 200ºC.

Product Overview Laundry ironing machine belts, also known as ironing machine guide belts or ironing belts in the industrial laundry sector, serve as critical conveying components in laundry equipment such as ironing machines, flatwork ironers, and folding machines. Primarily used to smoothly convey textiles like sheets, duvet covers, and tablecloths during ironing, these belts ensure consistent and efficient ironing quality by flattening and finishing fabrics. With the growth of the service industry and increasing demand for large-scale laundry processing, industrial washing equipment is evolving toward higher efficiency, automation, and specialization. As one of the most critical devices affecting linen processing capacity, the performance of ironing machines is paramount. The ironing machine belt, being its core component, directly determines the equipment's ironing efficiency, fabric flatness, and energy consumption performance.

Modern high-speed ironing machines operate at speeds up to 50 meters per minute, achieving a 40% efficiency gain over conventional models, placing heightened demands on their belts. Yonghang manufactures these belts in various materials, including pure cotton, synthetic fibers, and aramid, each with distinct performance characteristics and suitable applications. Among these, aramid ironing belts are most widely used in high-end industrial laundry equipment due to their exceptional heat resistance and tensile strength.

Advantages:

High resistance to abrasion

High breaking strength

High air permeability, allowing the belt to run dryer, and increasing the output of the ironer.

Our ironing belt has a soft felt surface giving a smooth high quality finish to the linen.

Materials and Structure

Washing and ironing machine belts can be manufactured from various materials based on different application requirements and operating environments:

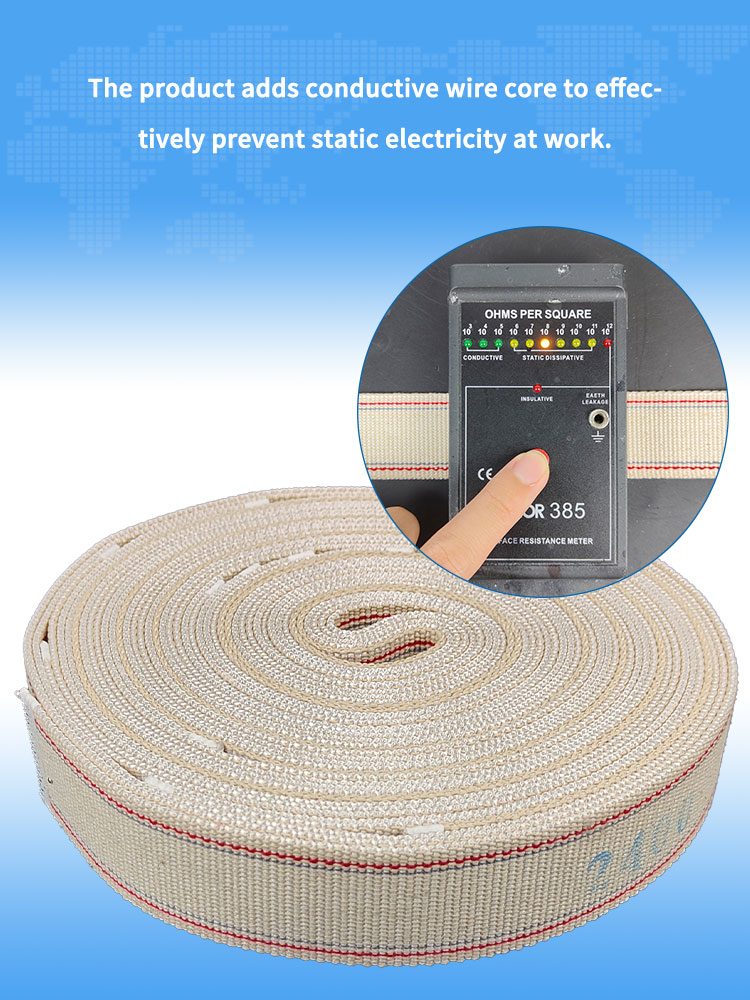

Aramid Material: Made from aramid fibers, it offers exceptional properties including high strength, high modulus, heat resistance, corrosion resistance, and low density. Aramid webbing typically maintains strength at elevated temperatures, resists melting, and delivers outstanding fatigue resistance and abrasion resistance. These belts often incorporate conductive yarns, providing static dissipation capabilities to effectively eliminate static electricity generated by friction during fabric ironing.

Other Materials:

Includes pure cotton guide belts (offering good breathability and moisture absorption, suitable for handling soft fabrics) and synthetic fiber guide belts (featuring abrasion resistance and high-temperature tolerance, ideal for fabrics requiring high wear resistance).

Connection Design

Ironing machine belts feature various joint connection designs. Common buckle types include:

Stainless Steel Buckle

Wolf Tooth Buckle

Spring Buckle

These connection designs facilitate easier belt replacement and installation. A specialized design incorporates a pair of circular double hooks embedded at each webbing end, connected via a hinge mechanism. Each webbing end is reinforced with a thermally fused adhesive layer. This design achieves a compact connection radius, ensuring seamless alignment with rollers. The structure is dense, robust, smooth, and flat, minimizing wear or fabric abrasion, thereby extending service life.

Laundry ironing machine belts are primarily used in the following environments and equipment:

Industrial laundries: Professional laundries in large institutions such as hotels and hospitals, handling large volumes of textiles including sheets, duvet covers, tablecloths, etc.

Washing equipment: Conveyor systems within ironing machines, flatwork ironers, folding machines, and similar devices

Fabric types: Suitable for various materials including pure cotton, synthetic fibers, and blended fabrics

Equipment Configuration and Innovation

Modern high-speed ironing machines feature compact designs such as “S”-shaped, double-sided ironing roller structures equipped with specialized differential speed mechanisms and variable frequency drive systems. These units typically employ pneumatic tensioning components and incorporate belt separator structures on each conveyor belt to eliminate the challenging issue of belt slippage during operation. Additionally, incorporating fabric release devices between linens and rollers prevents sticking, ensuring uninterrupted ironing operations.

Selection Considerations

When selecting suitable laundry ironing machine belts, consider the following factors:

Equipment Model and Specifications: Ensure belt width and thickness match the machinery.

Fabric Type Handled: Choose appropriate belt material based on primary fabric characteristics.

Production Efficiency Requirements: Opt for aramid belts with superior abrasion and heat resistance for high-speed production environments

Static Control Requirements: Prioritize anti-static belts when processing synthetic fabrics

Connection Type: Select appropriate buckle types based on equipment structure

In summary, laundry ironing machine belts serve as core components of industrial washing equipment, with their performance directly impacting ironing efficiency, quality, and operational costs. Selecting the appropriate belt type and maintaining it correctly can significantly enhance a laundry business's competitiveness and profitability.

Contact the Yonghang team to customize and procure your laundry ironing machine belts.

Contact Details