DA Double-sided tooth timing belts | Yonghang

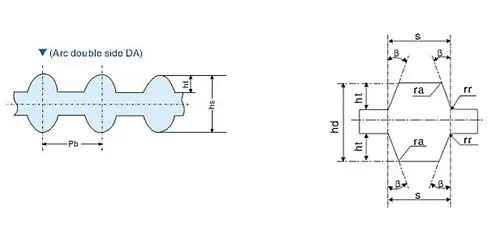

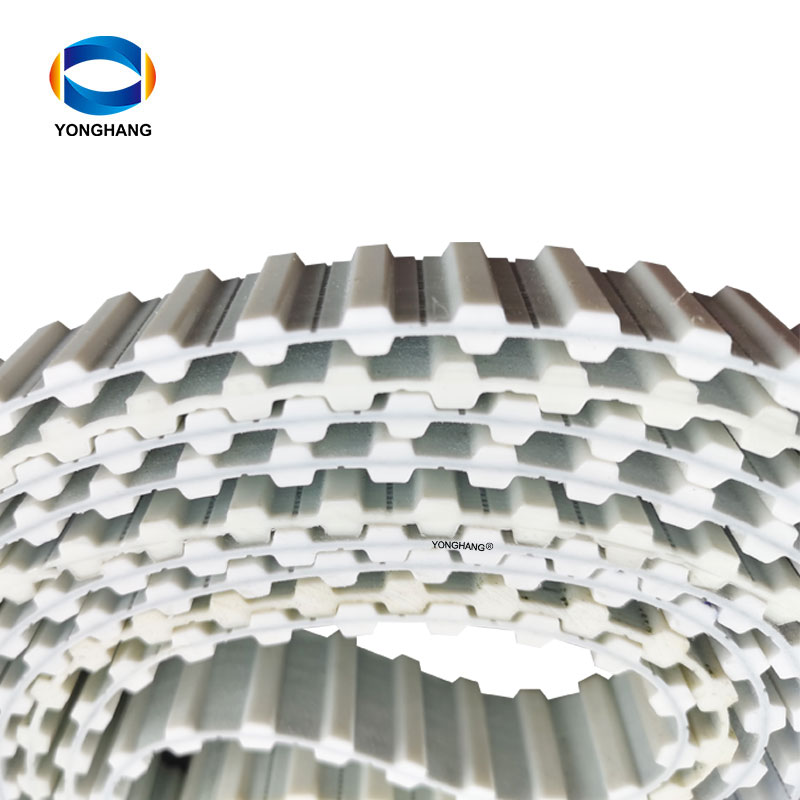

The pitch and tooth profile of Double-sided timing belt are same as the single-side timing belt.

Double-sided timing belt has two standard forms:

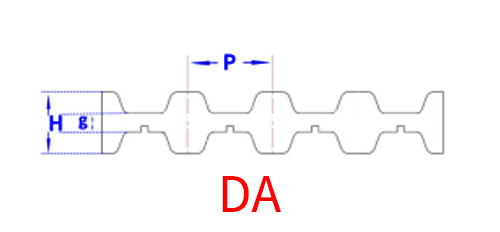

Model DA Symmetrical arrangement of the two-side teeth;

Model DB Staggered arrangement of the two-side teeth.

TO PLACE AN ORDER PLEASE CONTACT OUR EXPERIENCED AND PROFESSIONAL CUSTOMER SERVICE TEAM:

PHONE&Whatapp&wechat:+ 0086134 1810 3085

Email :sales@yhbelt.com

Product Introduction

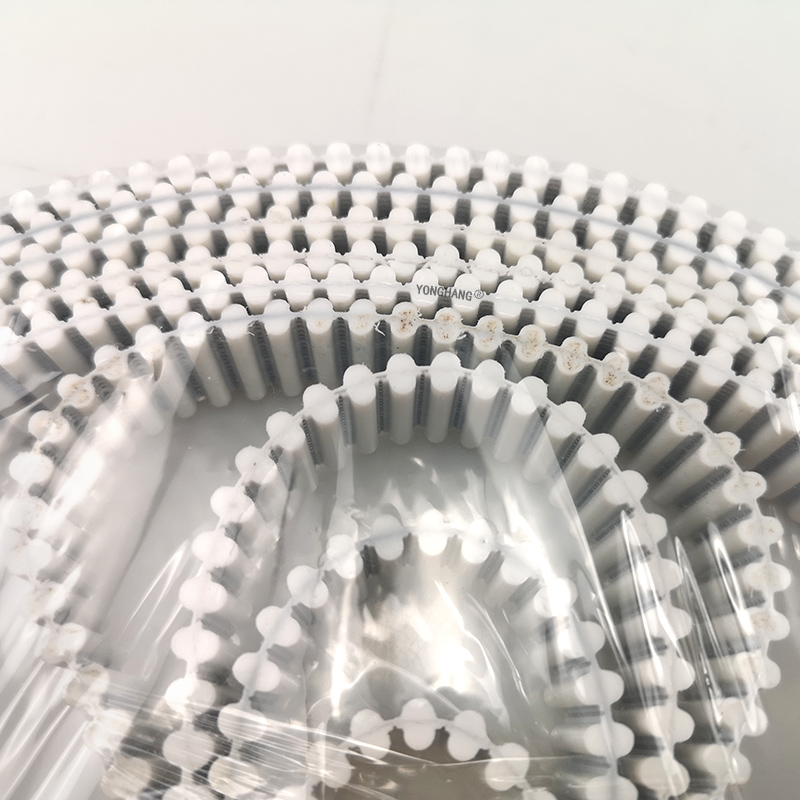

Color :black/white/grey/transparent

Size:DA Double-sided tooth

Length:Customized

Width:10-550mm

Material:TPU/Polyurethane

Type:Double-sided tooth

Shore hardness (A):PU 90° Shore A

Working temperature:-20-+80°C

Joint:Open/Endless with joint/Seamless (moulded)

Cords:steel/ kevlar

Product Information

DA Double-Sided Tooth Timing Belt: We offer two material options—rubber and PU. The rubber DA Double-Sided Tooth Timing Belt utilizes premium imported Japanese synthetic neoprene rubber blended with multiple specialized rubber additives. The skeleton material consists of high-quality imported Japanese glass fiber cord. The tooth surface is protected by a high-elasticity nylon 66 fabric.

This product features the same pitch and tooth profile as single-sided tooth timing belts.

Primarily designed for dual-sided transmission, it offers synchronous operation, simultaneous power transfer, and dual efficiency. Ideal for applications requiring a single belt to drive opposing directions, compact installation spaces, or high-precision linkage between primary and auxiliary drives, this product is recognized and widely adopted across machinery, textiles, precision instrumentation, petrochemicals, and telecommunication cable industries for its lightweight construction, slip-free engagement, and low-noise operation.

DA Double-Sided Toothed PU timing Belt features symmetrical tooth profiles on both sides, enabling low noise and vibration during forward and reverse transmission. Complies with FDA and RoSH certifications.Steel wire or Kevlar core.Joint:Open/Endless with joint/Seamless (moulded),Surface fabric and double-sided fabric or surface fabric, etc.

| type | g(mm) | H(mm) | pitch length(mm) | teeth |

| D-XL | 0.508 | 3.05 | 355.6-5405.12 | 70~1064 |

| D-L | 0.762 | 4.58 | 514.35-80000.00 | 54~ |

| D-H | 1.372 | 5.95 | 520.70-80000.00 | 41~ |

| D-XH | 2.794 | 15.49 | 1778.00-80000.00 | 80~ |

| D-XXH | 3.048 | 22.11 | 1778.00-6667.5 | 56~210 |

| D-T2.5 | 0.5 | 1.9 | 500.00-5000.00 | 200~2000 |

| D-T5 | 0.84 | 3.25 | 500.00-7000.00 | 100~1400 |

| D-T10 | 1.86 | 6.8 | 500.00-80000.00 | 50~ |

| D-T20 | 2.85 | 12.85 | 1700.00-80000.00 | 85~ |

| D-AT10 | 1.82 | 7 | 500.00-7000.00 | 50~700 |

| HTD.DA-3M | 0.76 | 3.2 | 501.00-6804.00 | 167~2268 |

| D-3M | 1.143 | 5.3 | 500.00-7000.00 | 50~1400 |

| D-8M | 1.372 | 8.1 | 512-80000.00 | 64~ |

| D-14M | 2.8 | 14.8 | 1750-8120 | 125~580 |

| D-S8M | 1.372 | 7.48 | 512-80000.00 | 64~465 |

| D-S14M | 2.8 | 13.4 | 1750~5012 | 125~358 |

| D-RP5M | 1.143 | 5.44 | 500.00-3100.00 | 50~620 |

| D-RP8M | 1.372 | 7.8 | 512.00-3720.00 | 64~465 |

| D-RP14M | 2.8 | 14.5 | 1764.00-4326.00 | 126~309 |

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details