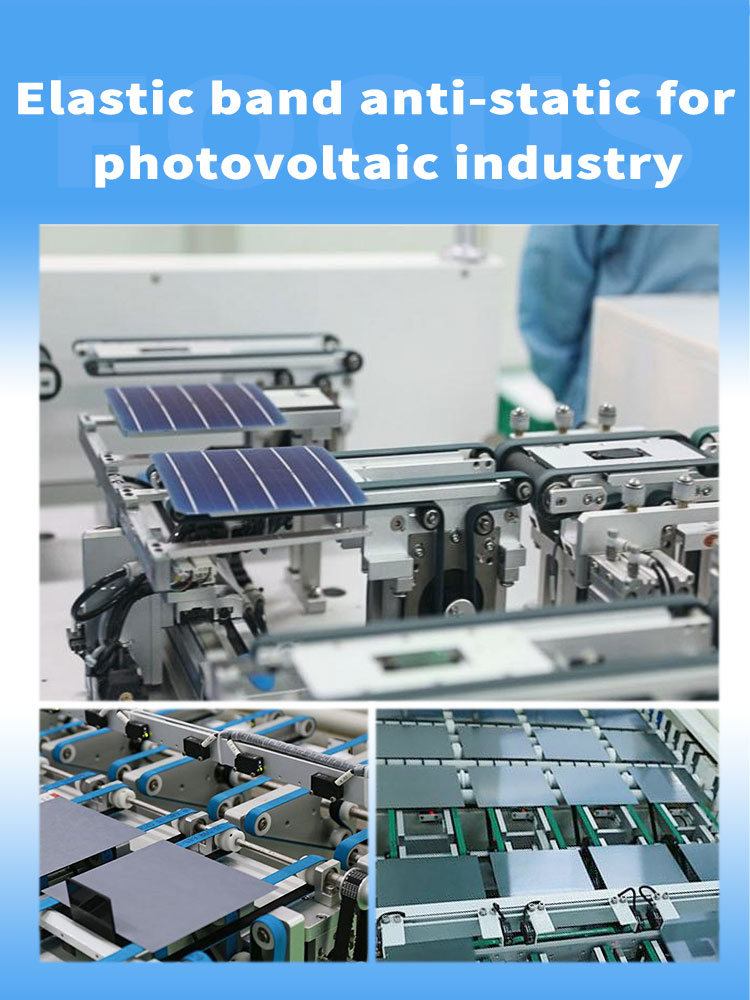

anti-static elastomeric belt for photovoltaic solar industry

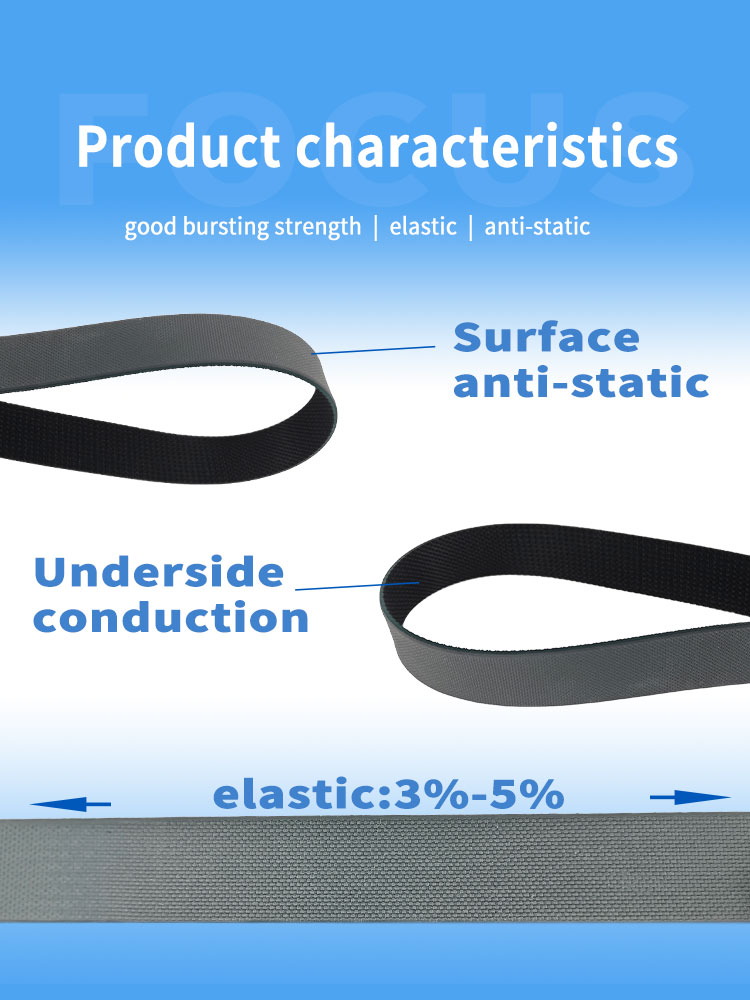

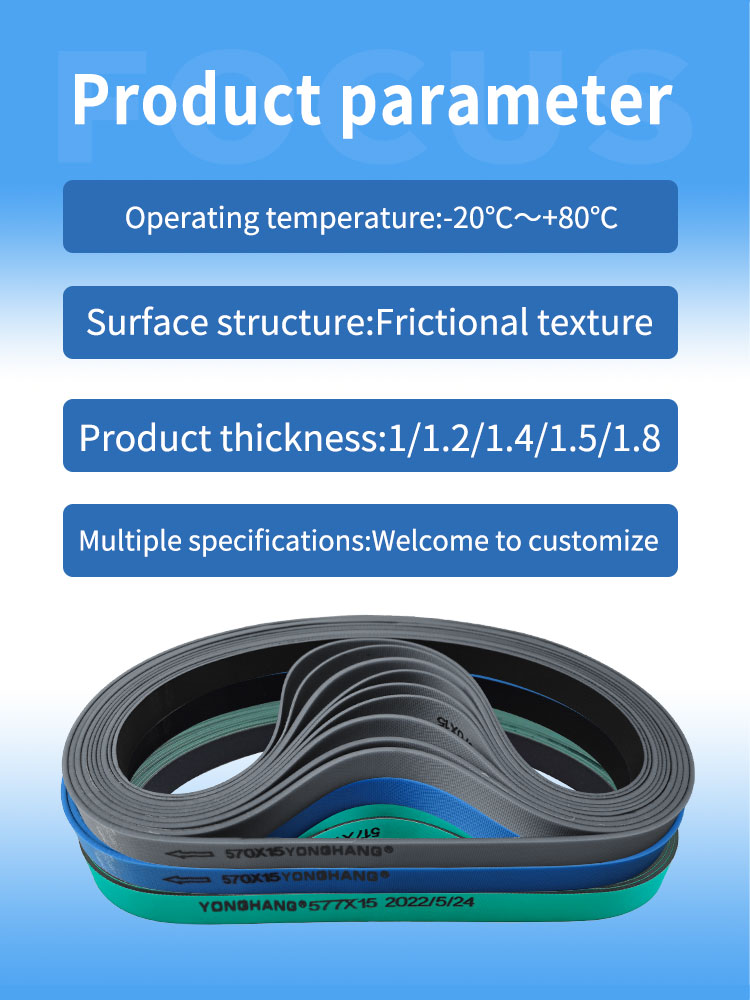

Photovoltaic solar flat belts, also known as elastic belts, are widely used in various industries for their excellent performance. It is mainly made of highly elastic polyurethane with an anti-static coating on the bottom and a thickness range of 1-1.5 mm. It has an expansion rate of about 3% and is available in a variety of colors such as green-black, blue-black and gray-black. With an allowable operating temperature range of -20 to 80 degrees Celsius, it is a versatile and reliable belt for a wide range of operating conditions. It has excellent abrasion resistance to withstand harsh environments, and is also known for its excellent stretchability to accommodate a wide range of sizes and shapes without compromising performance. It is designed to be less likely to mark products, ensuring a high quality finish.

Anti-static elastic belt Core functions and design highlights

Electrostatic protection technology: The surface resistance is stably controlled within the range of 6–9Ω, effectively preventing the accumulation of static electricity during production, and avoiding the degradation of photovoltaic module efficiency caused by electrostatic discharge (ESD) of the battery cells.

High Elastic Composite Material: Composed of weather-resistant synthetic rubber and anti-static fibers in a composite layer, it has self-repairing properties and can withstand high-frequency bending and stretching scenarios in the photovoltaic production line, significantly reducing material fatigue caused by mechanical stress.

Environmental Adaptability: Tested through salt spray corrosion and ammonia environment tests (in accordance with IEC 62716 standards), it can adapt to the production environment of photovoltaic modules in extreme climates such as deserts and high humidity areas.

Technical Specifications

Resistance characteristics: Surface resistance uniformity error ≤ 15%, in line with IEC 61340-5-1 electrostatic protection standard

Mechanical properties: Tensile strength ≥ 15 MPa, elongation ≥ 3%, supports dynamic mechanical loads (IEC 62782 standard)

Compatibility: Compatible with crystalline silicon, thin film and flexible perovskite battery production lines, width can be customized (8mm – 25mm). Application scenario

Application

Battery sheet transmission: Provides stable and static-free transmission during the cutting and welding processes, reducing the fragmentation rate.

Component packaging: Completes the precise alignment of EVA film and glass with the laminator to prevent bubble formation.

BIPV production: Suitable for the special cutting and assembly lines of building-integrated photovoltaic components.

standard thickness:1mm 2mm 1.25mm 1.5mm 2.5mm(Can be customized in thickness)

width:2-200mm(Within this range, cutting and customization for production can be carried out.)

Length range:100mm-100m/roll(We produce rolls of material. If you are looking to purchase in bulk, the price will be significantly reduced.)

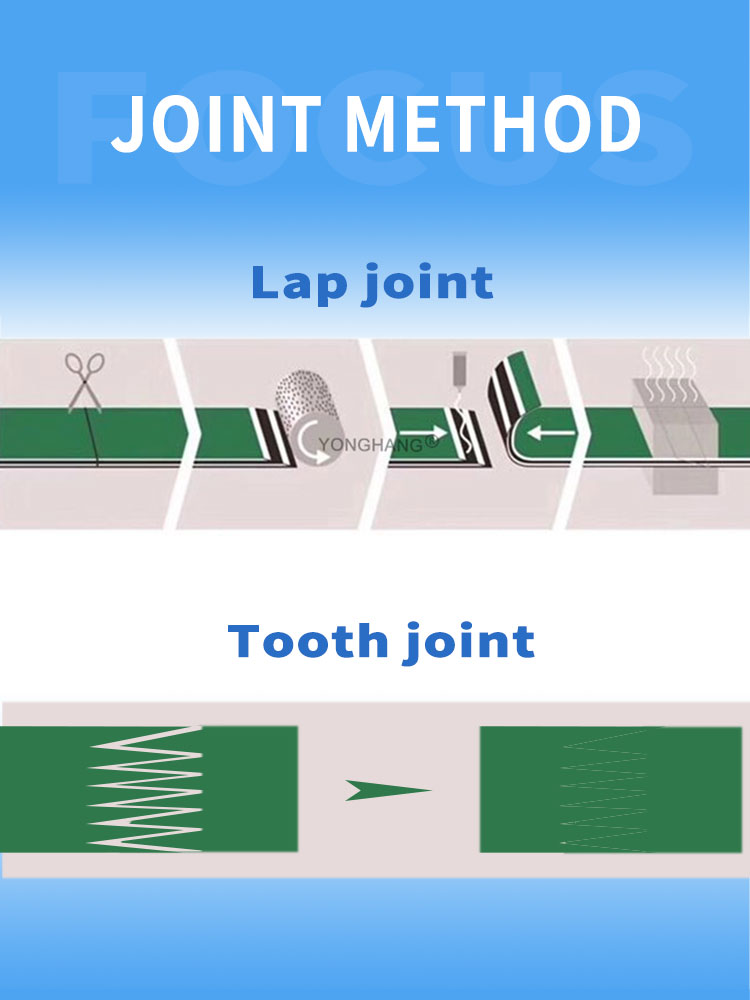

Joining methods: lap joint, butt joint, teeth joint,Anti-static elastic belt for photovoltaic solar industry Use teeth joint

colour:One side is black, the other side is grey, blue and green.

Contact Details