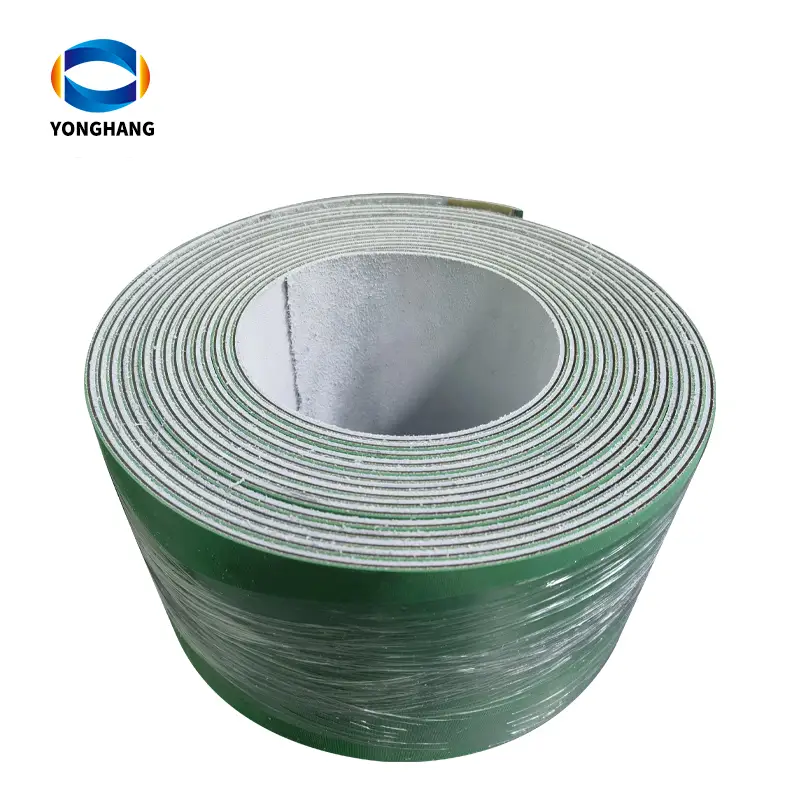

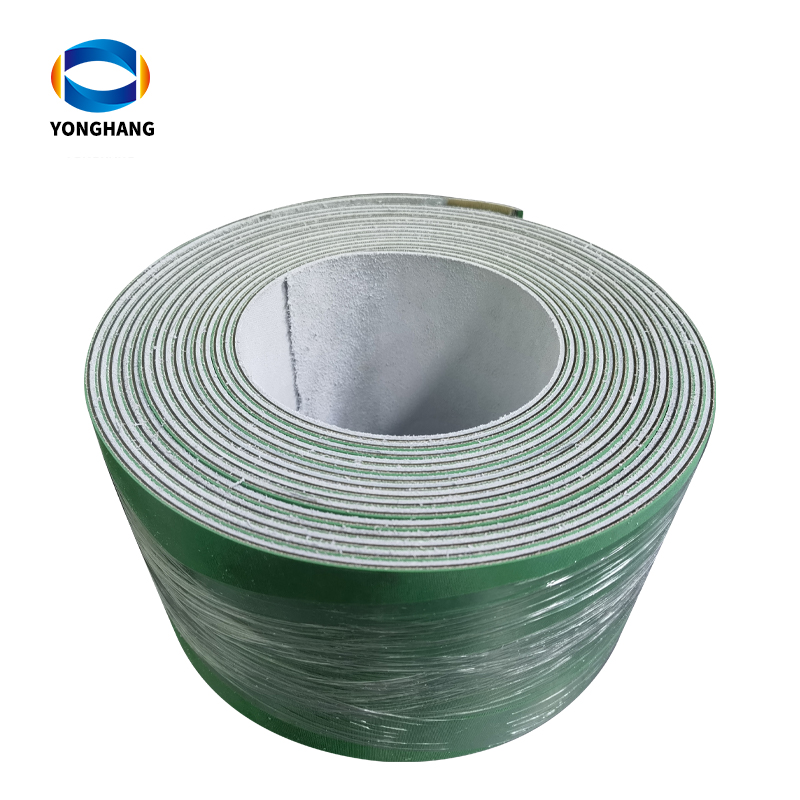

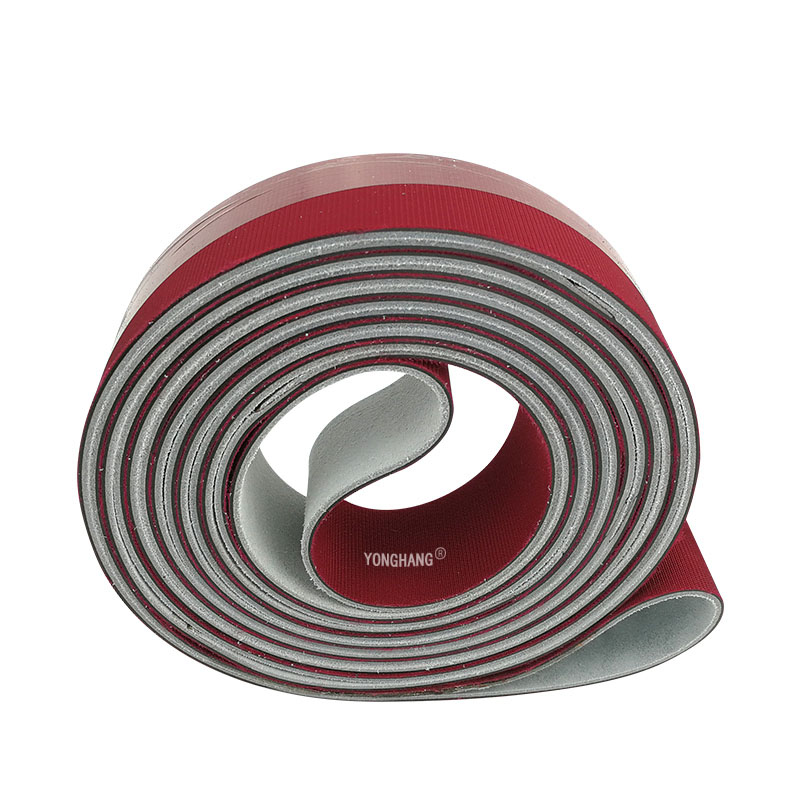

Leather-Fabric (LF)Sandwich Belts

Leather-Fabric (LF)Sandwich Belts are flat belts with high tensile Nylon (polyamide) as the core material, laminated on one sides with friction covering of Chrome Leather, Textile Fabric or Synthetic Elastomer.Very soft, durable, and highly tensile-resistant,Widely used in paper industry

Material:Nylon Fabric+Leather

Working temperature:-20-120℃

The high-temperature resistant leather-fabric (LF)sandwich belts is developed by improving upon the original leather belt. This belt retains the characteristics of the original leather belt while adding better adhesion, high-temperature resistance, material shrinkage elasticity, and corrosion resistance. It is commonly used in equipment such as glue box machines, automatic box sealing machines, and plastic packaging machines. During high-speed operation of the equipment and in harsh environments such as residual glue remaining on the belt surface and being blown by high-temperature air guns, the new high-temperature leather-fabric (LF)sandwich belts can handle these situations with ease, maintaining stable performance and lasting durability!

Yonghang Transmission belts has made changes to the connection method for this high-temperature belt structure due to its particularity. After multiple adjustments to the glue, process, and material itself, it has become more sturdy and stable in performance. It has received unanimous praise from the industry!

| Material | leather-fabric (LF) |

| Thickness | 3/3.5/4mm |

| Brand | yonghang |

| Belt Width | 10-200mm |

| Belt Length | 500-5000 mm |

| Country of Origin | China |

| Packaging Type | Roll |

| Tensile Strength | 20 MPa |

| Hardness | 40 ShoreA |

| Color | Red + gray, Green + gray |

| Features | High Strength, Durable, Cost-Effective, Reliable, Long Life, Smooth Running,high temperature resistance |

Types of Leather Sandwich Belts:

Leather-Fabric (LF): In this type of belt upper friction layer build from fabric, bottom friction layer consists chrome leather sheets and traction layer made from polyamide sheet.

Applications

1. Food Processing and Packaging

Application: Used for transporting baked goods, candies, meats, etc. The surface of the cowhide can reduce adhesion and facilitate cleaning, meeting food hygiene standards.

Advantage: Natural material is non-toxic and resistant to grease, suitable for scenarios where direct contact with food is required.

2. Light Industry and Precision Manufacturing

Application: In the electronics and textile industries for transporting precision components or fragile items. The cowhide surface is soft, preventing scratches on the products.

Advantage: Moderate friction coefficient, smooth operation, suitable for materials with high surface requirements.

3. Special Process Requirements

Application: Such as leather processing, paper printing, etc. The cowhide belt can provide uniform friction force and buffering protection.

Advantage: Wear-resistant and less prone to static electricity, suitable for processes sensitive to static electricity.

We are leading manufacturer, supplier and trader of extensive array of Transmission Belts. Our products are available as per the industry standards and in recommended specifications. We provide these products at industry leading prices.welcome to consult

Contact Details