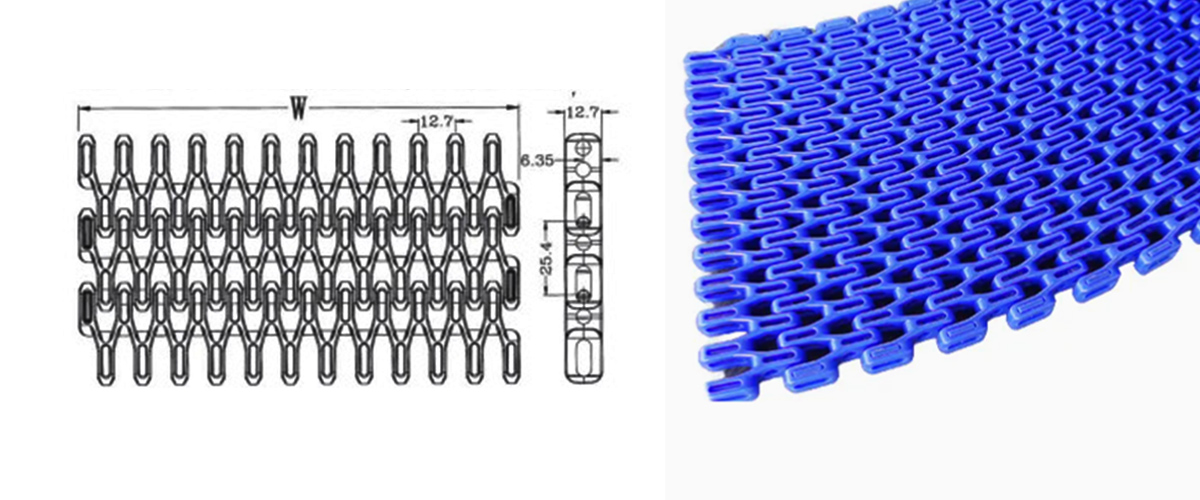

7100 series flush grid modular Conveyor belt Pitch 25.4

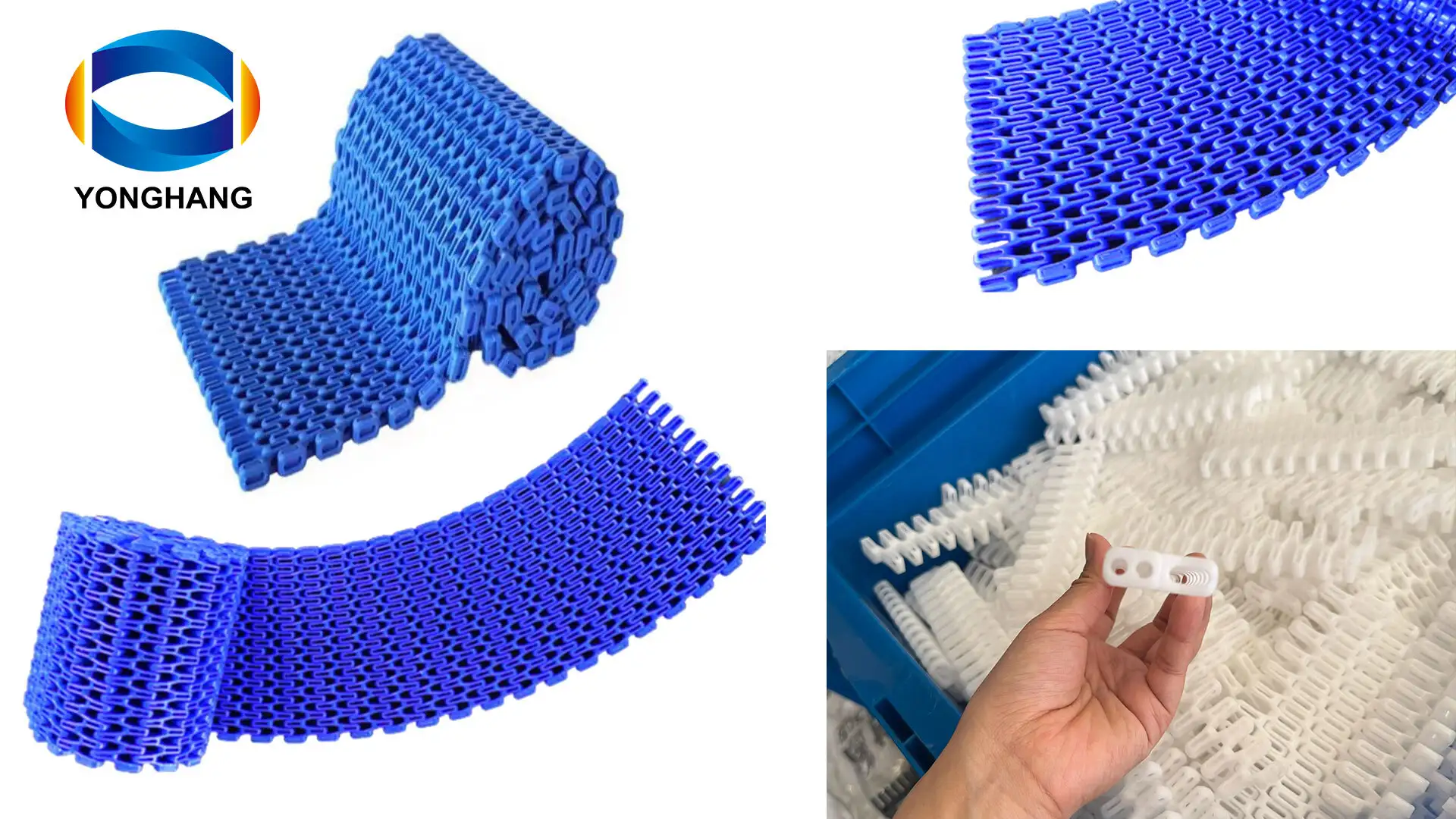

7100 series flush grid modular Conveyor belt

7100 series flush grid modular Conveyor belt

Pitch(mm): 25.4

Belt Material : POM

Pin Material: POM/PP/PA6

Temperature : POM:-30C°~ 80C° PP:+1°~90C°

Open Area :55%

Radius(Min) :2.3*Belt Width

7100 series flush grid modular Conveyor bel

| 7100 series flush grid modular conveyor belt | ||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Weight | thickness | Back flex radius (min) | Standard Width (Single piece) | Non-standard Width (Assembly) |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | mm | mm | |||

| 7100 | 25.4 | POM | PP | 5 | 25000 | 10 | 12.7 | 25 | 76/152 | 76+12.7*N |

| 25.4 | PA | 5 | 29000 | 10.1 | 12.7 | 25 | 76/152 | |||

| 25.4 | PP | PP | 5 | 16000 | 6.5 | 12.7 | 25 | 76/152 | ||

| Open Area 55% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | ||||||||||

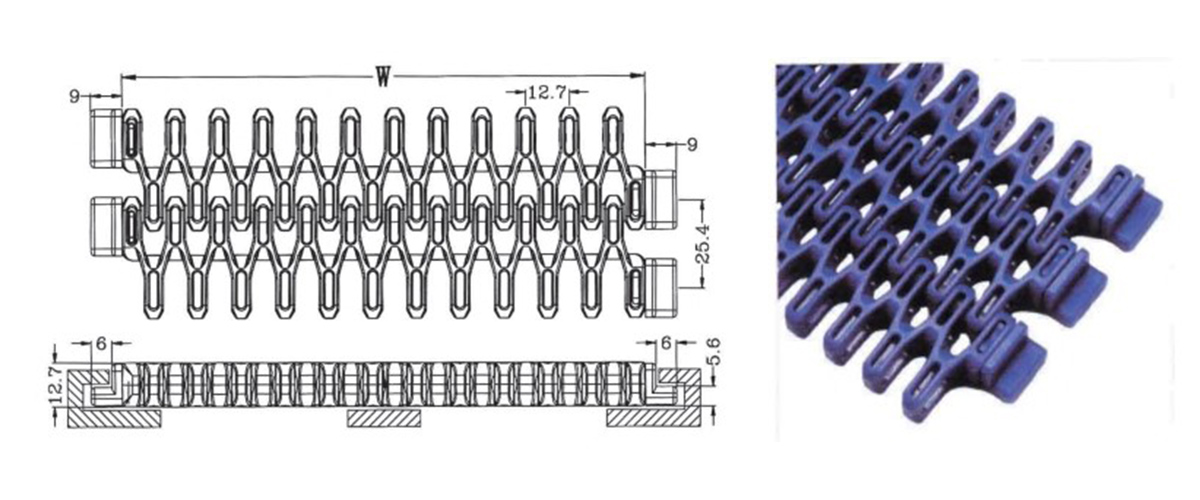

7100 Module Conveyor Belt Installation Guide Drawing

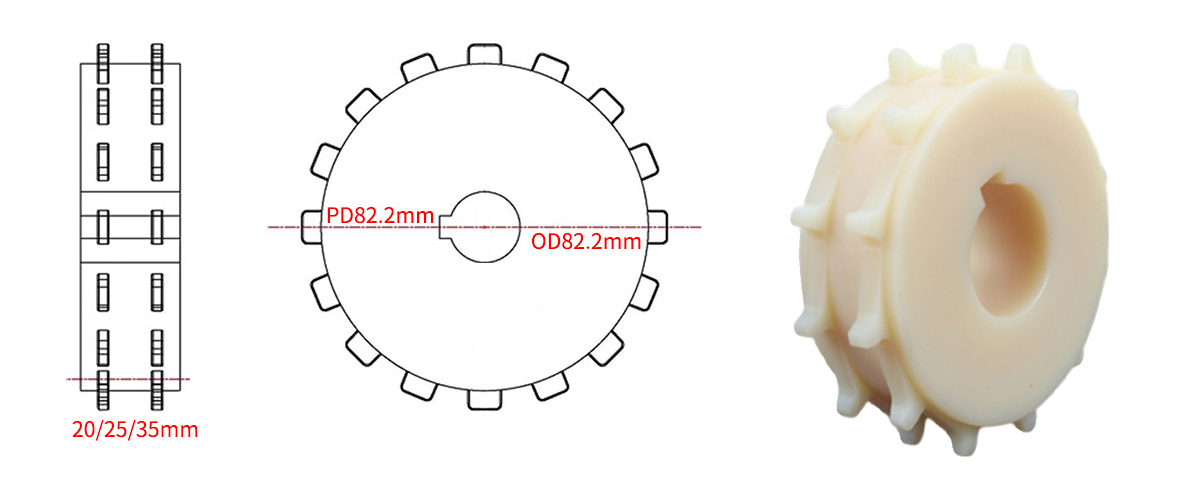

7100 Series Module Conveyor Sprocket

| Machined Sprockets | Teeth | Pitch Diametet (PD )mm | Outside Diameter (OD)mm | Bore Size | |||

| mm | Inch | mm | Inch | mm | |||

| 7100 | 9 | 74.3 | 2.92 | 73.8 | 2.9 | 20 25 35 | |

| 7100 | 10 | 82.2 | 3.23 | 82.2 | 3.23 | 20 25 35 40 | |

| 7100 | 12 | 98.2 | 3.86 | 98.8 | 3.88 | 25 30 35 40 | |

| 7100 | 15 | 122.2 | 4.81 | 123.5 | 4.86 | 25 30 35 40 | |

Product Information

7100 plastic flush grid modular conveyor belt, also call plastic steel belt, It is mainly used in plastic steel belt conveyor and it is a supplement to the traditional belt conveyor, it overcomes the belt machine belt tear, puncture, corrosion shortcomings, to provide customers with a safe, fast, simple maintenance of transportation. Due to it’s modular plastic belt and the transmission mode is sprocket drive,So it is not easy to crawling and running deviation, the modular plastic belt can withstand cutting, collision, and oil resistance, water resistance and other properties, therefore it will reduce the maintenance problems and related cost.

Advantages:

7100 Series Flush Grid Modular Comes with various openings including fine-mesh for water drainage and filtering

• Easily cleaned they are easy to wash down with water

• Reinforced product supports for high load elevators

• Strong and wear-resistant belt

• Closed and wide hinge design increasing product stability

• Edges allowing stability in side transfer applications

Application

Food Industry:

Snack Food(tortilla chips ,pretzels, potato chips,) ;Poultry,Seafood,

Meat (beef & pork) ,Bakery,Fruit & vegetables

Non-food Industry:

Packaging,Printing/Paper,Can manufacturing,Automotive,Tire manufacturing,Postal, Corrugated cardboard, Etc.

Material Physical and chemical properties

Acid and alkali resistance (PP) :

7100 modular plastic flush grid turnable conveyor belt using pp material in acidic and alkaline environment has better transport capacity

Antistatic material customized

We can produce material products with an anti-static value of 10E6Ω to 10E9Ω, This is a custom-made product. If you are interested, please contact us.

In addition, for the differences between POM PA materials, please refer to https://www.yhbelt.com/differences-between-POM-PP-PE-plastic-chain-plates.html

Contact Details