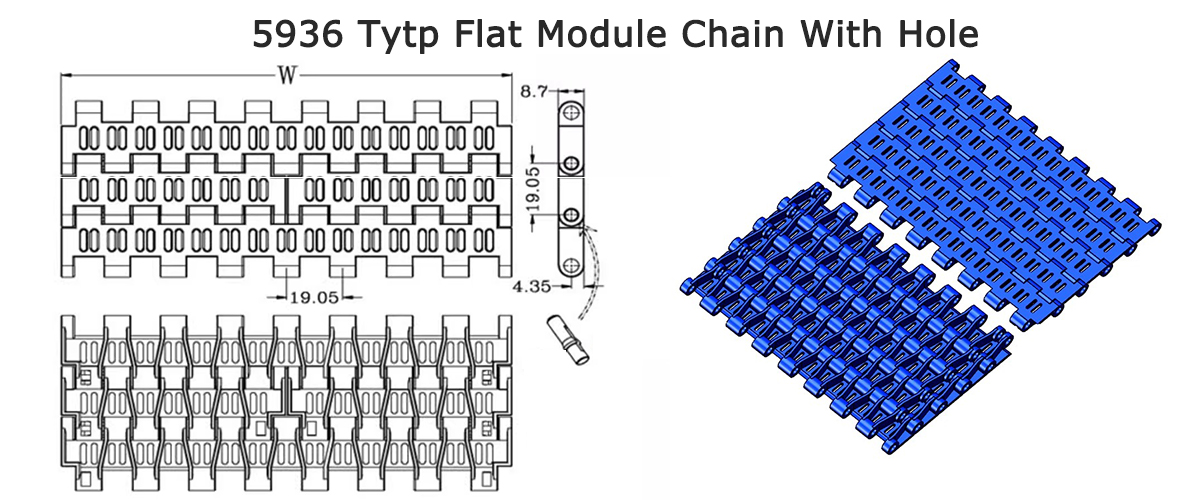

5936 Series Flat-Top Modular Conveyor Belt - Perforated Design

The 5936 flat-top modular conveyor belt combines a smooth conveying surface with precision perforation, providing an ideal solution for automated processes requiring drainage, ventilation, vacuum suction, or spray cooling. Widely used in food processing, packaging, and electronics assembly.

Pitch: 19.05 mm

Material: Polypropylene (PP), Polyethylene (PE), or Acetal (POM), with optional food-grade materials.

Operating Temperature:

POM: -20°C to +90°C

PP: -5°C to 105°C

Color:White, black, blue, etc. (customizable upon request)

Hole Diameter and Pitch:Customizable according to specific customer requirements.

| 5936 Series Flat-Top Modular Conveyor Belt - Perforated Design 19.05 pitch | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | working load(max) | weight | thickness | back flex radius (min) | work temperature | monolithic width | assemble width |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| 5936 Perforated Modular Belt | 19.05 | POM | PP | 4.35 | 13000 | 6.72 | 8.7 | 25 | -30℃~+80℃ | 76.2/152.4 | W=76.2*N

W=76.2*N+19.05*N |

| PA | 4.35 | 12000 | 6.82 | 8.7 | 25 | -30℃~+90℃ | 76.2/152.4 | ||||

| PP | PP | 4.35 | 7000 | 5.3 | 8.7 | 25 | +5℃~+105℃ | 76.2/152.4 | |||

| Open area:16% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

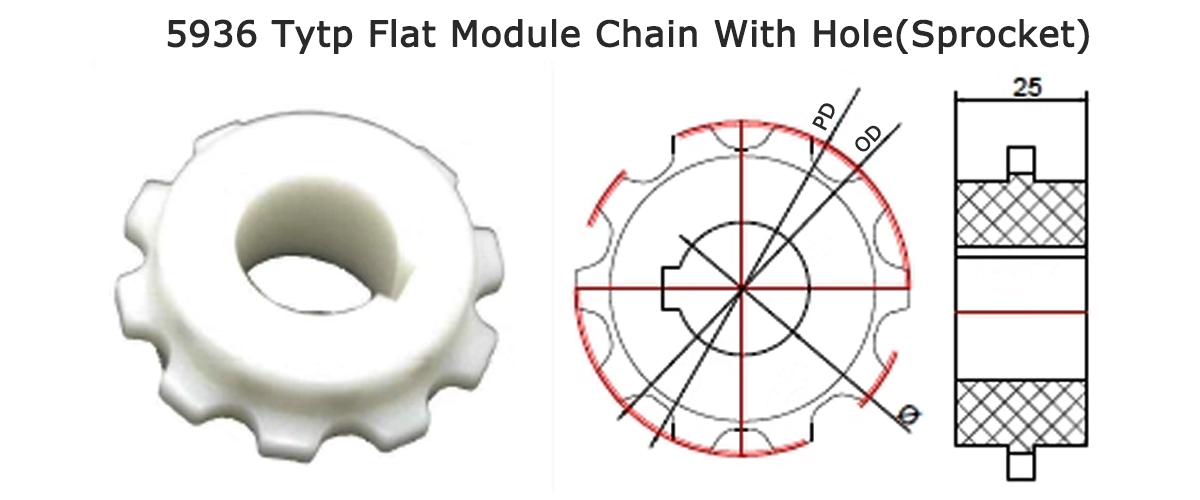

| Specification | Number of teeth | Outer diameter | Hole position | Material |

| 5936-10T | 10 | 63 | 25-45 | POM / PP / PE |

| 5936-12T | 12 | 74.6 | 30-60 | |

| 5936-13T | 13 | 80.3 | 30-60 |

Advantages and Features

Exceptional Surface Flatness

Provides stable, continuous support for products, particularly suited for conveying small, irregular items or packaged goods to prevent jamming and tipping.

Precision Perforation Design

Drainage and Drying: During washing, rinsing, or cooling processes, perforations rapidly expel moisture to accelerate product drying.

Vacuum Adhesion: Compatible with vacuum systems to securely hold lightweight or smooth products (e.g., paper, film, metal sheets), enabling precise positioning and incline conveyance.

Ventilation and Cooling: Allows unrestricted airflow to efficiently cool high-temperature products or meet specific process ventilation requirements.

Spraying and Inspection: Facilitates bottom spraying (lubrication, adhesive application) or visual inspection via sensors.

Modular Structure for Easy Maintenance

Modular design enables rapid replacement of damaged modules without dismantling the entire conveyor line, minimizing downtime and reducing maintenance costs.

Open hinge structure on both sides simplifies cleaning and effectively prevents bacterial growth, meeting hygiene requirements for food and pharmaceutical industries.

Applications

Food and Beverage Industry: Fruit and vegetable washing, pasteurization, freezing tunnels, beverage bottle and can drying, food packaging.

Packaging Industry: Conveying and positioning of cartons, bottles/cans, and packaging films; conveying systems for inkjet printers.

Electronics Manufacturing: PCB board cleaning, drying, and inspection lines.

Automotive Components: Cleaning, spraying, and assembly of small parts.

Logistics & Warehousing: Sorting systems and incline conveyors.

The 5936 flat-top modular perforated conveyor belt represents a smarter, more reliable conveying solution. Our expert team stands ready to provide technical support and customized solutions, helping you optimize processes and create greater value.

Selection and Application Recommendations

When selecting and using the 5936 Flat-Top Modular Conveyor Belt, please note the following:

Material Selection: Choose the appropriate material based on actual requirements. For example, PP (Polypropylene) typically meets food hygiene standards and offers high-temperature resistance (maximum operating temperature approx. 105°C), while POM (Polyoxymethylene) provides superior mechanical strength and wear resistance.

Accessory Customization: Add sidewalls (up to 50mm height or higher) and side skirts based on conveying requirements to prevent material spillage during inclines or high-speed transport.

Professional Consultation: For specific applications, particularly those involving extreme conditions (e.g., high/low temperatures, strong corrosion, heavy loads), consult Yonghang's supplier team to ensure optimal belt model and configuration selection.

Contact Details