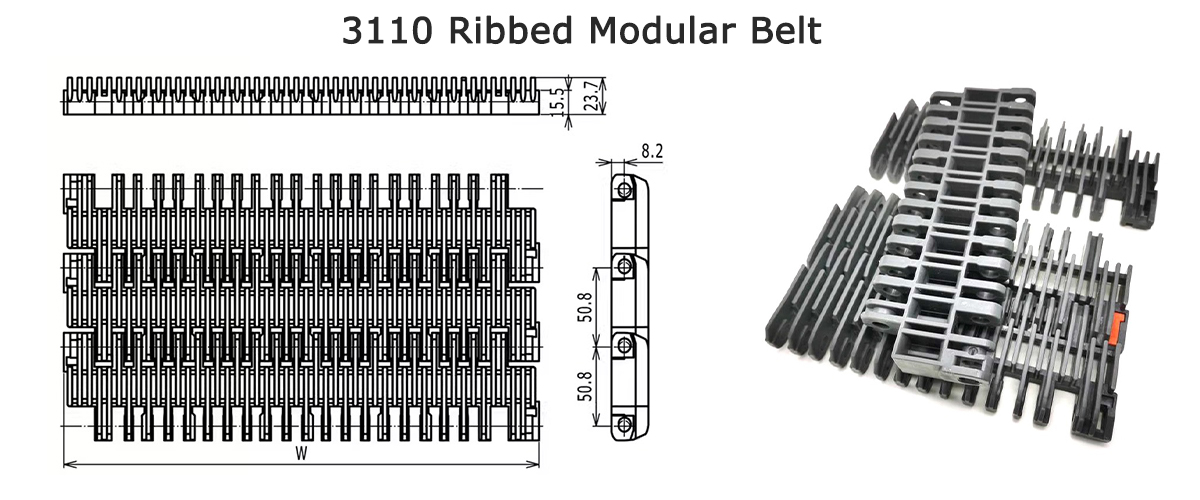

3110 Raised Rib Straight Run Modular Conveyor Belt

3110 Raised Rib Straight Run Modular Conveyor Belt Pitch: 50.8mm features a modular design. Injection-molded plastic modules are assembled into interlocking units via plastic hinge pins, achieving a “brick-laying” structural strength. Width and length can be customized as required.

Pitch: 50.8 mm

Thickness: 23.7 mm

Open Area: 23%

Material: PP (Polypropylene)

Working Load: 27000 N/m

Bending Radius: 75 mm

Working Temperature: 5 - 105°C

Feature Description:

Ribbed Structure Design: The raised ribs on the conveyor belt surface are ideal for maintaining product stability during transport, effectively preventing slippage and displacement.

Superior Drainage and Ventilation: A 23% open area ensures excellent drainage and airflow, suitable for washing, drying, sterilization, and similar processes.

Exceptional Durability: Constructed from PP plastic, it offers wear resistance and corrosion resistance for extended service life. Complies with food industry standards.

| 3110 Ribbed Modular Belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | working load(max) | weight | thickness | back flex radius (min) | work temperature | monolithic width | assemble width |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| 3110 Raised Rib Modular Belt | 50.8 | PP | PP/PA | 8.2 | 27000 | 11.32 | 23.7 | 75 | +5℃-+105℃ | 72.6*N | 72.6*N |

| 50.8 | POM | PP/PA | 8.2 | 24000 | 10.8 | 23.7 | 75 | -20℃~+85℃ | 72.6*N | ||

| Open area:26% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

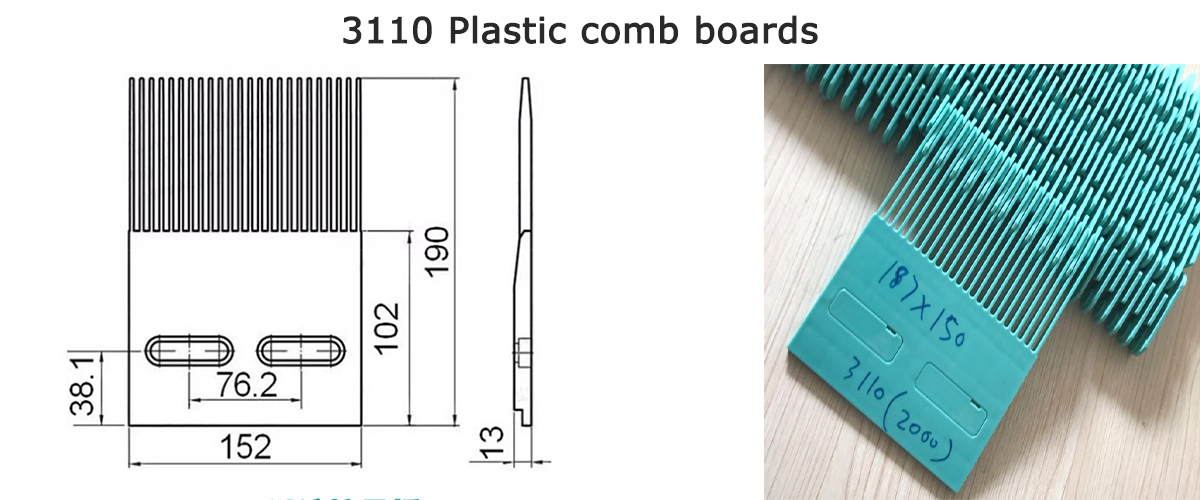

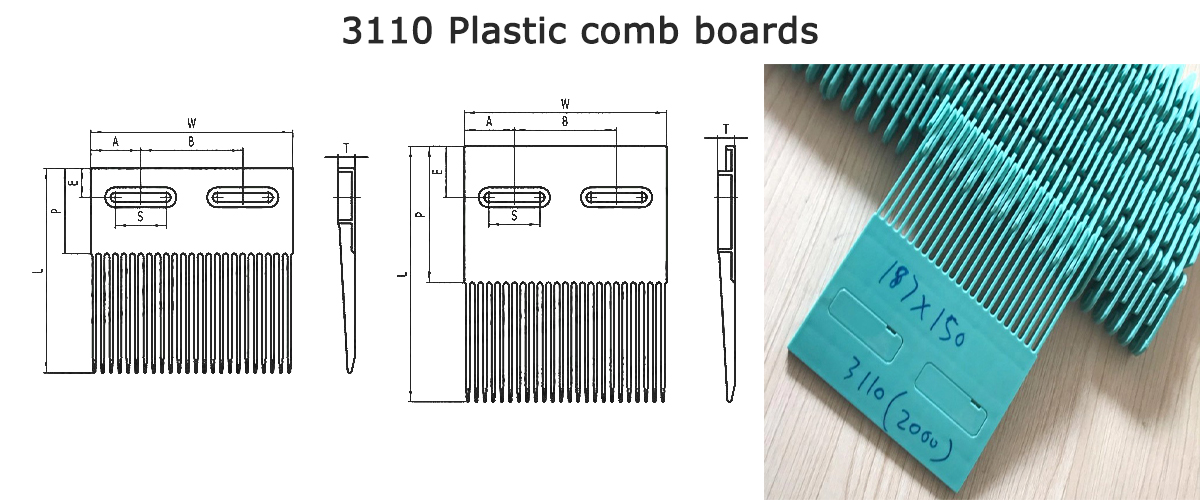

Code | 3110 Plastic comb boards Dimensions | |||||||||||||||

| L | W | P | E | T | A | B | S | |||||||||

| mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | |

| TC3110-01 | 152.4 | 6 | 150.9 | 5.94 | 63.5 | 2.5 | 21.6 | 0.85 | 12.7 | 0.5 | 37.4 | 1.47 | 76.2 | 3.0 | 38.1 | 1.5 |

| TC3110-02 | 190.5 | 7.5 | 150.9 | 5.94 | 101.6 | 4.0 | 38.1 | 1.50 | 12.7 | 0.6 | 37.4 | 1.47 | 76.2 | 3.0 | 38.1 | 1.5 |

Advantages

Exceptional Stability and Traction: The convex ribbed surface provides outstanding traction for bottles, cans, and pouched products, preventing slippage during horizontal or inclined conveyance and ensuring smooth, efficient production line operation.

Superior Drainage and Sanitation: The smooth, non-porous modular design resists bacterial growth. A 23% open area efficiently drains liquids and debris, facilitating easy cleaning and meeting stringent sanitation standards in food, pharmaceutical, and other industries.

High Strength and Long Service Life: PP material delivers excellent wear and corrosion resistance, withstanding a working load of 27,000 N/m. Ideal for heavy-duty and continuous operation environments.

Easy Maintenance and Cost Savings: Modular design allows replacement of only damaged sections, eliminating the need to replace entire belts during partial damage. This significantly reduces downtime and maintenance costs.

High-Temperature Compatibility: Operates reliably in temperatures ranging from 5°C to 105°C, making it ideal for temperature-controlled processes like high-temperature sterilization and frozen food processing.

Application

Beverage and Bottling Industry: Widely used for conveying beverage bottles and aluminum cans, suitable for specialized equipment such as bottle storage platforms, sterilization machines, and bottle cooling machines.

Food Processing and Packaging: Suitable for conveying needs in puffed food production lines, fruit grading, packaging lines, meat product conveyance, and various automated packaging production lines.

High-Temperature and Cold Chain Processing: Its temperature resistance makes it ideal for high-temperature sterilization lines while also supporting cold chain logistics segments like frozen food production lines.

Pharmaceutical and Cosmetics Industry: Meets stringent hygiene and stability requirements during the transportation, cleaning, and packaging of pharmaceutical and cosmetic containers.

Contact Details