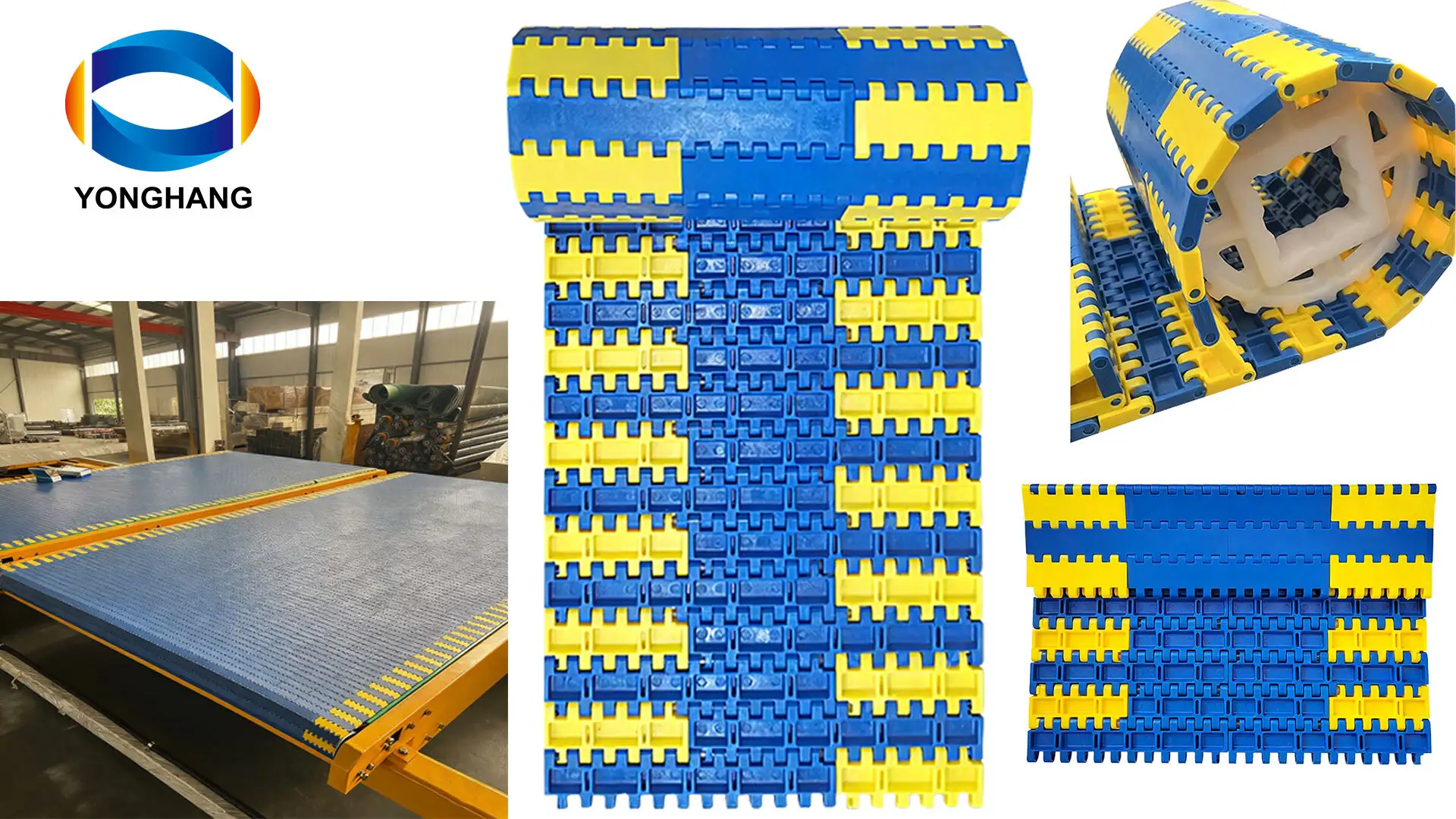

2540 Flat Top Modular Plastic Conveyor Belt for Heavy Duty Corrugated Industry

2540 Corrugated Paper plastic modular Conveyor Belt, Cardboard Processing Stacker modular Conveyor Belt, Heavy-Duty Conveyor Belt, Pitch 25.4mm

colour:Blue + Yellow

Bending radius(Minimum value)mm 25mm

Weight (kg/㎡) By detail and material classification

Length Scope(mm) Any length

Width Scope(mm) 76.2*N

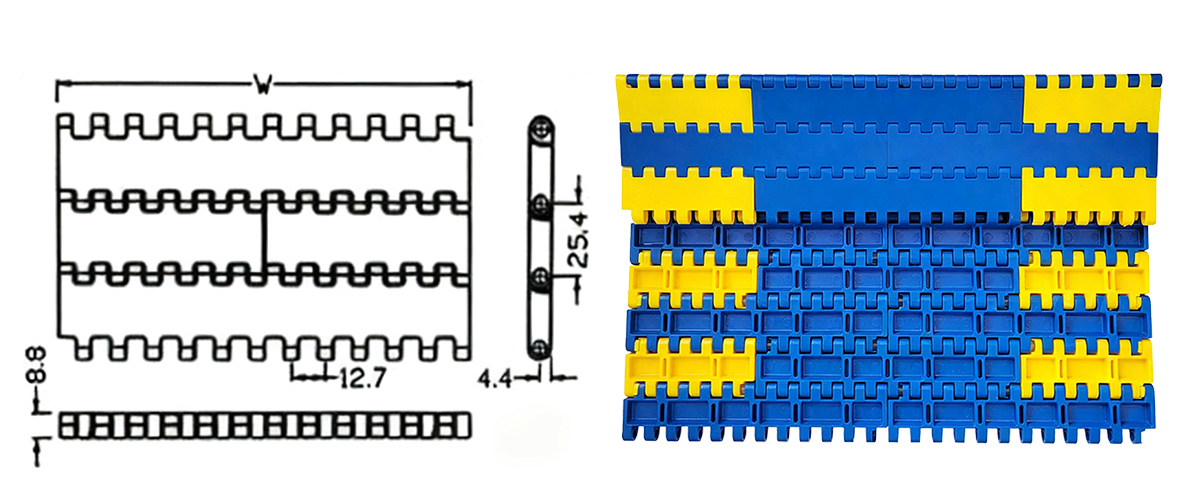

Thickness Scope(mm) 8.8mm

Tensile Strength(N/m) 21℃ POM 40000N

product description

2540 Flat Top Modular Plastic Conveyor Belt for Heavy Duty Corrugated Industry is a specific type of plastic conveyor belt with a 1.0-inch (25.4mm) pitch, designed with a smooth, solid surface to transport a wide range of products. The "2540" denotes its pitch, a standard measurement for modular belts, and the term "Flat Top" indicates its smooth, unbroken surface, often compared to a flat belt but with the advantages of modular design, such as easy cleaning, and quick repair or replacement.

Corrugated paper modular conveyor belts are made of individual, interlocking plastic modules designed for durability, precision, and ease of maintenance in the heavy-duty corrugated paper industry. These systems streamline the material handling of cardboard boxes, sheets, and related products throughout the manufacturing and packaging process, from printing and folder-gluing to stacking and scrap collection. Their modular design allows for flexibility in system configuration and simple, cost-effective replacement of damaged parts.

Advantages

· Solves production line logistics issues

· Automates corrugated cardboard handling

· Ensures high-quality corrugated board

· Prevents damage to bottom sheets in stacks

· Optimizes output and storage efficiency

Surface free of pressure marks, enhancing corrugated board quality

The 2540 series flat plastic module conveyor belt provides a stable, continuous transport surface, eliminating relative displacement of boards during conveyance. This prevents creep and deformation, reducing board wastage.

Smooth conveyance maintains stable corrugated stacks

High stack stability without damaging bottom boards

Board conveyance requires no interleaving, preventing creases

The 2540 series chain plates possess exceptional load-bearing capacity, maintaining a relaxed state during normal operation without excessive tension. They excel in high-load, extended-length conveying sections. This reduces labor costs, enhances operational efficiency, and performs tasks unattainable by manual labor. Its user-friendly operation meets the demands of modern industrial production.

Heavy-duty, 2540 plastic modular conveyor belts boost enterprise productivity

High safety standards prevent accidents

The 2540 plastic modular conveyor belt's interlocking structure offers excellent tear and impact resistance. Simple maintenance reduces equipment downtime and saves maintenance time and costs.

The 2540 plastic modular conveyor belt provides a stable conveying platform, preventing workshop personnel from walking on the conveyor belt and avoiding falls or accidental injuries, ensuring worker safety.

Increases paper stack height, optimizing output and storage efficiency.

Distinctive conveyor belt edge design emphasizes operational range.

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | Working load(max) | Working temperature | Weight | thickness | Width (Single piece) | Back flex radius (min) | Width (Assembly) |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | mm | mm | ||||

| 2540 | 25.4 | POM | PP | 4.1 | 40000 | -40℃~80℃ | 9 | 8.8 | 76.2*N | 25 | 76.2+25.4*N |

| 25.4 | PA | 4.1 | -40℃~90℃ | 10.4 | 8.8 | 76.2*N | 25 | ||||

| 25.4 | PP | PP | 4.1 | -4℃~100℃ | 8.8 | 76.2*N | 25 | ||||

| 25.4 | PE | PE | 4.1 | -40℃~65℃ | 8.8 | 76.2*N | 25 | ||||

| Open Area:0% N,n will increase as integer multiplication;Width reduction:Actual will be lower than standard width 0.1%-0.3%. | |||||||||||

| Machined Sprockets | Teeth | Pitch Diametet(mm) | Outside Diameter | Bore Size | Other Type | ||

| mm | Inch | mm | Inch | mm | Available On request | ||

| 2540-12T | 12 | 98.1 | 3.86 | 96.8 | 3.81 | 25 30 35 40 50 | By Machined |

| 2540-18T | 18 | 146.3 | 5.75 | 146.1 | 5.75 | 40 50 60 | |

| Special tooth counts can be customized. The shaft diameter can be square or round/D keyslot. The injection molded Sprockets material can be POM, PP, or PA. The machined material can be PA/PP. | |||||||

about us

1.We are a professional Transmission belts manufacturer, our product line contains modular belt, slat top chain, timing belts(PU and rubber),PUlleys,Conveyor belts

2.We Cooperated with DHL & Amazon to Help Them Solve Multi-scenario Application Parcel Sorting

3.In China, we help 20,000 companies solve transmission system solutions.

4.yonghangbelt not only has a complete production line to meet different application needs, but also can provide comprehensive product knowledge and experience.

5.After 20 years of innovative research and development, we can provide more than 5000 kinds of solutions to provide perfect support for you in the field of Transmission and transportation.

6.We have an experienced foreign trade team with global delivery capabilities.And we will offer you the lowest transportation cost.

7.We hope to recruit one agent in each country in Central and South Asia, the Middle East, Africa, and Russia for in-depth cooperation. We guarantee the quality of our products and the lowest prices. You are responsible for local sales, installation, and after-sales service.

Yonghang transmission Belt is a well-known company in China. Our founders and co-founders both have 20 years of experience in the transmission industry. We have a group of employees who have worked for 10 years, 8 years, and 5 years.

Our vision is: to ensure that mechanical equipment operates continuously. Our slogan is: never stop, set sail.

Certificate

We hold more than 40 national authorized patents and software certifications

Allseries of modular Plastic chain plate products have obtained the US "FDA" food grade certification And "EU" certification in Europe

Obtained "ISO9001-2008" quality management system certification

If you are interested in this product, please contact me.

Contact Details