210L-17+3 White Rubber Coating Seamless Timing Belts for sewing machine

210L-17+3 White Rubber Coating Seamless Timing Belts for sewing machine

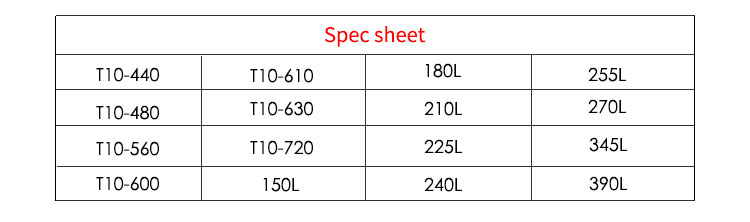

Adopt mould one - piece vulcanization molding process, seamless without interface.all kinds of specifications can be customized, length, width and thickness of coated, surface coated can be added with red,white,green coated etc., can be perforated according to requirements, and drawings need to be provided.

Product description

Designed specifically for industrial sewing machines, embroidery machines and other precision textile equipment, this 210L-17+3 white rubber-coated seamless timing belt is an indispensable high-performance transmission component in modern sewing workshops. Seamless and integrated vulcanization, without layers, not prone to breaking, and truly wear-resistant rubber-coated seamless timing belt.

Advantage:

Precision Synchronization, Eliminates Skipping

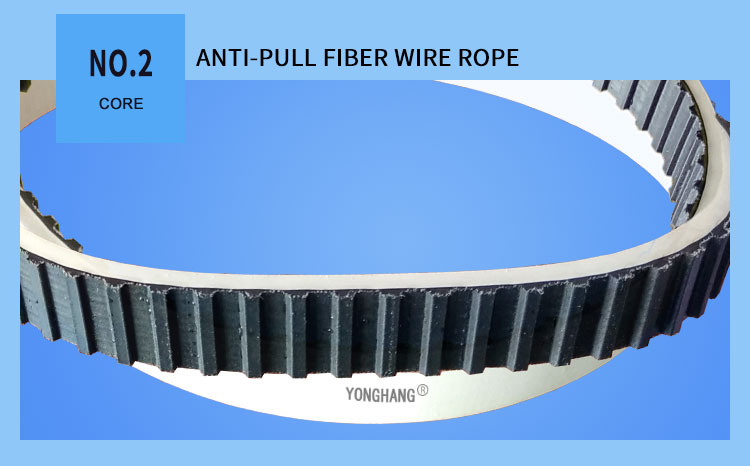

Utilizing high-strength fiberglass cables as the reinforcement layer ensures minimal elongation. Precise tooth profile design and seamless construction enable perfect meshing between the belt and equipment gears, completely eliminating skipping, tooth slippage, or phase errors during transmission. This guarantees flawless precision in every stitch.

White Rubber Coating: Exceptional Grip and Quiet Operation

The unique white rubber-coated surface delivers an extraordinary coefficient of friction and superior grip, ensuring efficient and smooth power transmission.

Seamless Monolithic Construction: Ultra-Smooth Operation

The seamless, monolithic structure completely eliminates vibrations, impacts, and noise that may occur in traditional spliced belts during high-speed operation. This enables smoother, more stable equipment operation, significantly reduces wear, and extends the lifespan of core equipment components.

Exceptional Flexural Fatigue Resistance

Its superior resistance to flexural fatigue ensures the belt maintains a long service life even under frequent starts/stops and high-speed cycles.

Clean White Finish, Easy Maintenance

The white belt surface clearly shows wear and contamination, facilitating timely equipment maintenance and cleaning. Its material resists ink and dust adhesion, helping maintain internal equipment cleanliness—ideal for textile and apparel production environments with high cleanliness requirements.

Technical Specifications:

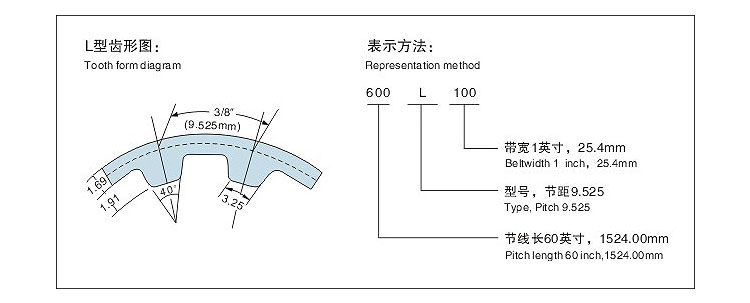

Model: 210L-17+3

Length: 21inch

Width: 17mm

Thickness: 3mm

Construction: Seamless

Surface: White rubber coating

Reinforcement: Glass fiber cord

Applications :

Widely applicable to high-performance industrial flat-seam sewing machines, overlock machines, quilting machines, computerized embroidery machines, quilting machines, and other textile machinery and automated equipment requiring precision synchronous transmission across various brands.

- Year Established2014

- Business TypeFactory

- Country / RegionCHINA

- Main IndustryBearing Accessories

- Main Productshaul off belts, Pull down belts ,Rubber flat belt ,Coating timing belt,PU Timing belt ,ATM belt ,V belts,Rubber Timing belts,conveyer belts

- Enterprise Legal Personjunliang yang

- Total Employees201~1000 people

- Annual Output Value10000wUSD

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated CustomersGates,Continental,Optibelt,synchroflex,nitta,bando,optibelt

YONGHANG strictly implements ISO9001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging industry, pipe wire and cable industry,food packaging industry, wood chopsticks carpentry industry, and so on.

YONGHANG production full range of standard and special products designed to satisfy specific customers requirements.Products sell well in China, Southeast Asia, the Middle East and actively explore the European, American and Russian markets. The company and a number of well-known enterprises to establish a good partnership.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

Contact Details