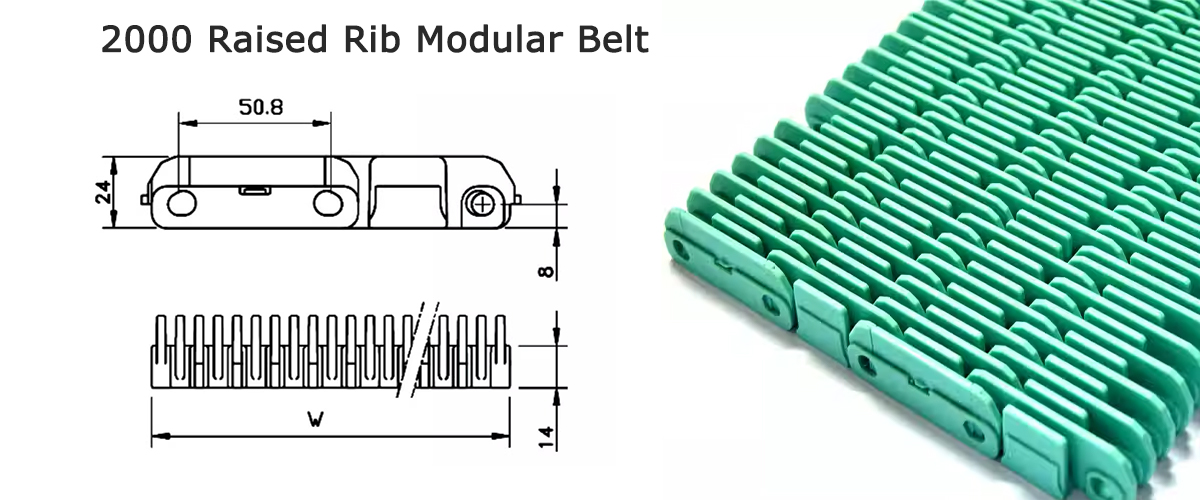

2000 Raised Rib Modular Belt Pitch 50.8mm

The 2000 Series Raised Rib Modular Conveyor Belt is a high-performance engineering plastic conveyor belt engineered to meet the demanding requirements of modern industrial applications. Its unique raised rib surface structure delivers exceptional traction and product stability while effectively guiding liquids and debris, ensuring clean and efficient conveying operations. This makes it an ideal choice for food processing, packaging, bottling, and diverse manufacturing industries.

Belt material:POM/PP

Belt Pitch:50.8mm

Operating Temperature: POM: -20°C to +90°C PP: -5°C to 105°C

Color:White, black, blue, etc. (customizable upon request)

| 2000 Raised Rib Modular Belt | |||||||||||

| Belt type | Pitch | Belt material | Pin Material | Pin Diameter | working load(max) | weight | thickness | back flex radius (min) | work temperature | monolithic width | assemble width |

| mm | mm | N(21℃ | Kg/m2 | mm | mm | dry | mm | mm | |||

| 2000 Raised Rib Modular Belt | 50.8 | POM | PP | 7.2 | 27380 | 11.32 | 24 | 75 | +5℃-+104℃ | 76.2*N | 152.4+76.2*N |

| 50.8 | PP | PP | 7.2 | 29500 | 10.6 | 24 | 75 | +5℃-+104℃ | 76.2*N | ||

| 50.8 | |||||||||||

| Open area:26% (N,n will increase as integer multiplication; due to different material shrinkage,Actual will be lower than standard width 1%-3% | |||||||||||

Product Advantages

Exceptional Traction and Stability:

Ribbed Design: The ribbed surface securely grips products, preventing slippage, rolling, or shifting during inclined or high-speed conveyance. Particularly suitable for bottles, cans, and bagged goods.

Superior Drainage and Debris Removal:

Gaps between ribs provide smooth flow channels for liquids, wash water, and fine debris, effectively reducing product contamination, maintaining belt cleanliness, and simplifying cleaning procedures.

High Strength and Long Service Life:

Manufactured from high-performance engineering plastics (e.g., polypropylene PP, polyethylene PE), it offers exceptional wear resistance, impact resistance, and fatigue resistance, withstanding heavy loads and continuous operation.

Modular Design for Easy Maintenance:

Unlike traditional monolithic belts, this product consists of interconnected modules. Localized damage requires replacing only the affected section, eliminating the need for full belt replacement. This significantly reduces downtime and maintenance costs.

Simple installation and disassembly, with flexible customization of length and width to match conveyor dimensions.

Superior Hygienic Properties:

Smooth, non-porous surface resists bacterial growth and facilitates easy cleaning and disinfection.

Excellent Air Permeability:

The spaced structure provides ideal airflow channels for cooling, heating, or drying processes, enhancing overall process efficiency.

Application

Food and Beverage Industry:

Food Processing: Fruit and vegetable washing, frozen foods, baked goods, confectionery, meat and poultry processing.

Packaging Industry:

Carton forming, filling, and sealing machines; labeling machines; and various automated packaging lines.

Pharmaceutical and Personal Care Industry:

Conveying, cleaning, and packaging of medicine bottles and cosmetic containers.

Automotive and Electronics Manufacturing:

Conveying and assembly of small components.

Logistics and Distribution Centers:

Used in sorting systems and parcel handling.

Contact Details